Study on the Suitability of Baking Processing for Yak Stomach with Different Muscle Layer Thicknesses

-

摘要: 本研究以牦牛不同肌层厚度胃共17个样品为研究对象,分析其原料肉理化品质、加工品质和食用品质及经过烤制后理化、加工、食用和感官评价差异,建立了综合品质评价模型Y=0.33A1−0.05A2+0.12A3+0.26A4+0.35A5(A1~A5分别代表b*值、剪切力、泡沫稳定性、起泡能力、弹力)。结果表明,肚领1.5~1.8 cm、瓣胃1.0~1.2 cm、网胃0.6~1.2 cm适宜烤制加工,网胃0.5 cm、瓣胃0.5~0.9 cm、皱胃0.6~1.2 cm较适宜烤制加工。同时,以总体可接受性为因变量,综合品质评价为自变量建立回归方程Y=1.570X−0.258,方程拟合系数R2=0.906,进一步证明综合品质评价模型可较好地反映牦牛不同肌层厚度胃的烤制加工适宜性。通过烤制加工指标及原料肉进行相关性分析对比得出乳化活性高、乳化稳定性高、蛋白质含量高、且拥有较好的弹力的部位适合烤制加工。该研究为牦牛不同肌层厚度胃的精深加工提供理论依据。Abstract: In this study, 17 samples of yak stomach with different muscle layer thickness were taken as the raw meat, and the physicochemical quality, processing quality and eating quality of raw meat and the physicochemical, processing, eating and sensory evaluation differences after baking were analyzed. A comprehensive quality evaluation model Y=0.33A1−0.05A2+0.12A3+0.26A4+0.35A5 (A1~A5 represents b* value, shearing force, foam stability, foaming ability, elasticity) was established. Results showed that those stomach were suitable for roasting, which were the rumem with the muscle layer thickness were 1.5~1.8 cm, the omasum with the muscle layer thickness were 1.0~1.2 cm, and the reticulum with the muscle layer thickness were 0.6~1.2 cm. While the reticulum with the muscle layer thickness was 0.5 cm, the omasum with the muscle layer thickness were 0.5~0.9 cm, and the abomasum with the muscle layer thickness were 0.6~1.2 cm, which were less suitable for roasting. At the same time, the regression equation Y=1.570X−0.258 was established with the overall acceptability as the dependent variable and the comprehensive quality evaluation as the independent variable, and the fitting coefficient of the equation was R2=0.906, which further proved that the comprehensive quality evaluation model could better reflect the suitability of the roast processing of the stomachs with different muscle thicknesses of yak. Through the correlation analysis and comparison of grilling processing indexes and raw meat, it was concluded that the parts with high emulsification activity, high emulsification stability, high protein content and good elasticity were suitable for grilling processing. This study provides a theoretical basis for the deep processing of yak stomachs with different muscle thickness.

-

Keywords:

- yak stomach /

- muscle layer thickness /

- baking /

- processing suitability

-

牦牛胃是可食性副产物,共有4个室,分为瘤胃(Rumem)、网胃(Reticulum)、瓣胃(Omasum)和皱胃(Abomasus)[1]。2022年我国屠宰牦牛约380万头,胴体产量约48.6万吨[2],比2020年多屠宰10万头,胴体产量增加0.6万吨[3]。随着消费者对牦牛肉的需求增加,牦牛胃的产量也逐渐增加。

牦牛胃中含有丰富的蛋白质、钙离子、钾离子、多糖等多种营养物质和矿物质[4],其加工方式主要以卤制、煮制、涮制或用于重组肉加工。烤制类食品作为料理美食[5],因其风味独特、色泽诱人深受消费者们的喜爱。传统的烤制方式存在环境污染、火炉的温度难以统一等现象,因此,炭烤逐渐被电热、微波等方式代替,且经过电烤后的制品,非挥发性物质含量高于炭烤,味道优于传统烤制方式[6],因此,烤制食品成为加工方式的主要方式之一。影响烤肉的主要因素包括:烤制方式、烤制温度和烤制时间[7],同时原料肉的品质与烤制牛胃产品品质具有直接关系,包括肉色、持水能力、质地、嫩度、滋味等[8]。宋洁[9]研究发现不同月龄或不同部位的羊肉脂肪含量、蛋白质含量、肌纤维直径、嫩度、风味等方面存在一定差异,所适宜的加工方式不同。罗天林[10]将牛瘤胃、皱胃、肠分割后,在沸水中预煮后切片,放入烤箱中架空烘烤,研究发现不同脏器的保水性、色泽、风味、多汁性等存在一定的差异,不同脏器具有不同的选择性。郝婉名[11]研究发现,不同部位的西门塔尔杂交牛的品质特性有显著差异,不同部位肉所加工的制品适宜性也不同。王妍[12]确定牦牛肚领和非肚领部位的最佳烤制工艺,且在最佳工艺条件下,肚领与非肚领部分的加工损失、剪切力、质构具有差异。综上所述,不同部位肉的加工特性存在差异,所适宜的加工适宜性也不同。然而目前关于牦牛胃烤制加工适宜性评价方法与评价体系方面的研究较少,牦牛胃不同肌层厚度烤制加工适宜性尚不明确。

本实验以牦牛胃不同肌层厚度为研究对象,分析其烤制前后理化品质、加工品质、食用品质及感官品质的差异,明确烤制加工的关键品质指标,建立烤制加工适宜性评价模型,利用回归分析结合感官评价对模型进行验证,筛选适宜进行烤制加工的牦牛胃不同肌层厚度,为牦牛胃的合理化提供理论依据。

1. 材料与方法

1.1 材料与仪器

牦牛瘤胃、网胃、瓣胃和皱胃 均采自青海百宸食品有限公司。采集9副36±6月龄,生长发育良好、体况相近的牦牛。宰后在3±1 ℃条件下运回实验室后将污物、黑膜及黏膜清洗干净,备用;无水乙醇、甲基红、溴甲酚绿、硫酸、氯化钠、盐酸、氢氧化钠、硼酸 上海源叶生物科技有限公司;所有试剂均为分析纯;大豆油 中粮福临门营销有限公司。

HHS-4S电热恒温振荡水浴锅 上海宜昌仪器纱筛厂;UV 2550紫外可见分光光度计 日本岛津公司;C-LM3B质构仪 美国Brookfield公司;FA1204B电子天平 上海天美天平仪器有点公司;DHG-9030A鼓风干燥机 上海一恒科学仪器有限公司;800A 多功能粉碎机 深圳艾尔莎科技有限公司;PSH-2A可调高速匀浆机 杭州研和实验仪器有限公司:K1160凯氏定氮仪 济南海能仪器有限公司;ADC-50-C全自动测色色差计 北京辰泰克仪器技术有限公司。

1.2 实验方法

1.2.1 牦牛胃的分割

选取9副牦牛瘤胃、网胃、瓣胃和皱胃,用游标卡尺先将瘤胃分为肚领1.5~1.8 cm与非肚领部位,再将非肚领部位、网胃、瓣胃及皱胃的肌层厚度进行测量和分割,分别分割为1.0~1.2 cm、0.6~0.9 cm、0.5 cm、0.2~0.4 cm。

经过预实验结果,肚领1.5~1.8 cm、四个胃1.0~1.2 cm、0.6~0.9 cm、0.2~0.4 cm中间厚度品质差异不显著(P>0.05),因此,最终将牦牛胃按肌层厚度分先为瘤胃肚领1.5~1.8 cm及非独领部分,再按照肌层厚度将瘤胃非独领部分、瓣胃、网胃、皱胃分别分割为1.0~1.2 cm,0.6~0.9 cm,0.5 cm及0.2~0.4 cm,共17个样品。

1.2.2 烤制加工

参考王妍[12]的方法并结合预实验结果进行改进:

烤制:原料—切块烤制—冷却—成品(待测样品)。

将牦牛胃不同肌层厚度修整切型,切成长4 cm、宽2 cm、烤制温度为180 ℃、烤制时间为20 min,放于恒温的烤箱中进行烘烤,烘烤10 min时翻面一次,保证原料肉双面受热均匀,收集烤制样品,冷却至室温,待测。

1.2.3 原料肉及烤制理化品质指标测定

1.2.3.1 蛋白质

采用凯氏定氮法,具体参照GB/T 5009.5-2016《食品中蛋白质的测定》[13]。

1.2.3.2 水分

采用直接干燥法,具体参照GB 5009.3-2016《食品中水分的测定》[14]。

1.2.4 原料肉及烤制加工品质指标测定

1.2.4.1 蒸熟损失

参考李升升[15]的方法并做改进,将100 g左右不同厚度牛胃称重记为W1,放入80 ℃恒温水浴锅中加热30 min,用吸水纸吸取蒸煮后牛胃表面的水分后称为Wn,蒸煮损失按下列公式进行计算:

(1) 式中:CL为蒸煮损失,%;W1为肉样蒸煮前的重量,g;Wn为肉样蒸煮后的重量,g。

1.2.4.2 热收缩率

参考李升升[15]的方法并做改进,用最小刻度1 mm的卡尺测定每个样品沿肌纤维方向的长度。样品未经过加工处理前的长度L1,样品经过加工处理后的长度记为Ln,试验重复3次,结果取其平均值,长度热收缩率按下列公式计算:

(2) 1.2.4.3 离心损失

参考陈玉茹[16]的方法并做改进,将50 mL离心管中放入脱脂棉,脱脂棉的高度为5.5~6.0 cm。切取不同厚度牦牛胃5 g左右,立即放置于精度为0.0001 g的分析天平上称重,记为m3。用定性滤纸将样品包裹后放入装有脱脂棉的离心管中,在4 ℃下,转速9000 r/min离心10 min。取出样品,去除滤纸,再次精准称量,记为m4。离心前后肉样的重量损失占其原重量的百分比即为离心损失,按下列公式进行计算:

(3) 式中:m3为肉样离心前的重量,g;m4为肉样离心后的重量,g。

1.2.5 蛋白质功能特性

1.2.5.1 蛋白提取方法

参考王妍等[17]的方法并做改进,取100 g样品,加入300 mL 0.6 mol/L NaCl溶剂分散,然后调节pH至11,在组织捣碎机中以8000 r/min速度间歇匀浆2 min,然后将匀浆液在恒温环境中连续搅动2 h后,在1000×g转速下离心15 min,过滤,取上清液,备用。

1.2.5.2 乳化能力和乳化稳定性

参考PEARCE等[18]的方法并做改进,取蛋白匀浆液和大豆油按3:1(体积比)混合,在高速匀浆中剪切乳化1 min。分别在乳化0 min和10 min时吸取200 μL至离心管中,用0.1%SDS稀释到10 mL,将0.1%SDS作为空白,在500 nm下测定吸光值,分别记为A0、A10。EA(乳化活性)和ES(乳化稳定性),按下列公式进行计算:

(4) (5) 式中:△t为时间间隔,10 min。

1.2.5.3 起泡能力和泡沫稳定性

参考PLANCKEN等[19]方法并做改进,在室温条件下,将一定浓度的蛋白液调节pH至7.0,随后取100 mL置于容器内,在转速为15000 r/min的高速分散器中间歇搅打2 min,记录均质后的液面高度,为V0,静置30 min后再记录液面高度,为V30。FC(起泡能力)和FS(泡沫稳定性),按下列公式进行计算:

(6) (7) 式中:V0为均质后的液面高度,mL;V30为静置30 min后液面高度,mL。

1.2.6 原料肉及烤制食用品质指标测定

1.2.6.1 肉色

参考张萌等[20]的方法并做改进,测定前对仪器进行校准,将切好的不同厚度牦牛胃放置于光线充足的试验台上30 min后,垂直将色差仪镜头置于样品上,随机在每个样品的5个不同位置各测定1次,测定位置为瘤胃、网胃、瓣胃、皱胃外面。记录所测得亮度(L*)值、红度(a*)值、黄度(b*)值。

1.2.6.2 剪切力

参考李升升等[21]的方法并做改进,将经过蒸煮后的不同厚度牦牛胃切割成大小为2 cm×1 cm×厚度的长条状,置于质构仪进行垂直方向剪切,实验探头采用TA3/100探头,夹具为TA-SBA,测定参数为:测试速度4.5 mm/s,下压距离为75.0 mm。将厚度不足1 cm的根据系数相乘得到结果,重复测定5次,结果取平均值。

1.2.6.3 质构

参考张燕等[22]的方法并做改进,将经过蒸煮后的不同厚度牦牛胃切割成1 cm×1 cm×厚度的方块状,质构仪参数测定为:探头TA3/100,夹具为TA-DEC,目标形变70%,触发点负载5g,测试速度为4.5 mm/s,可恢复时间5s,循环次数2.0.重复测定5次,结果取平均值。

1.2.7 烤制感官评价

参考GB/T 22210-2008《肉与肉制品感官评定规范》[23],挑选9位经过培训选拔的品评员组成的评价小组。试验前准备好矿泉水、牙签等物品,并告知感官评价员试验所应注意事项,感官评价整体过程中保持安静,使感官评价员综合考虑牦牛胃不同肌层厚度加工产品的感官品质共有属性,对烤制牦牛胃的外观、色泽、嫩度、多汁性和风味五个方面进行评分。采用10分制并将感官评分分为三段,制定如表1所示的牛胃熟制品感官评价标准。

表 1 烤制感官评分表Table 1. Roasted sensory scale项目 适宜(8~10) 较适宜(6~7.9) 不适宜(0~5.9) 外观 外观易于接受 外观可接受度中等 外观不易接受 色泽 表面色泽均匀,有光泽 表面色泽与光泽度中等 表面色泽过深或过浅,无光泽 嫩度 肌丝易咬断,有嚼劲 肌丝不易咬断,嚼劲性小 肌丝难咬断,无嚼劲 多汁性 汁液丰富,易下咽 多汁感较好 口感粗糙,难下咽 风味 肉香浓郁 肉香柔和 轻微肉香或香气不协调 整体可接受性 完全可以接受 比较可以接受 不能接受 1.3 数据处理

每个试验重复3次,结果表示为平均值±标准差(M±SD)。采用SPSS 26.0对数据进行统计分析和主成分分析;各组间差异用Duncan’s式比较;所有统计分析的显著水平均为P<0.05;绘图采用Origin2021;实验涉及不同量纲、不同单位、不同作用效果指标,为了便于加工适宜性综合评价,对各指标进行正向化与标准化处理,对指标进行正向化、标准化[23]。参考张文霖[24]的方法,用主成分分析确定关键指标权重。

2. 结果与分析

2.1 牦牛胃不同肌层厚度原料品质指标分析结果

2.1.1 牦牛胃不同肌层厚度理化指标分析结果

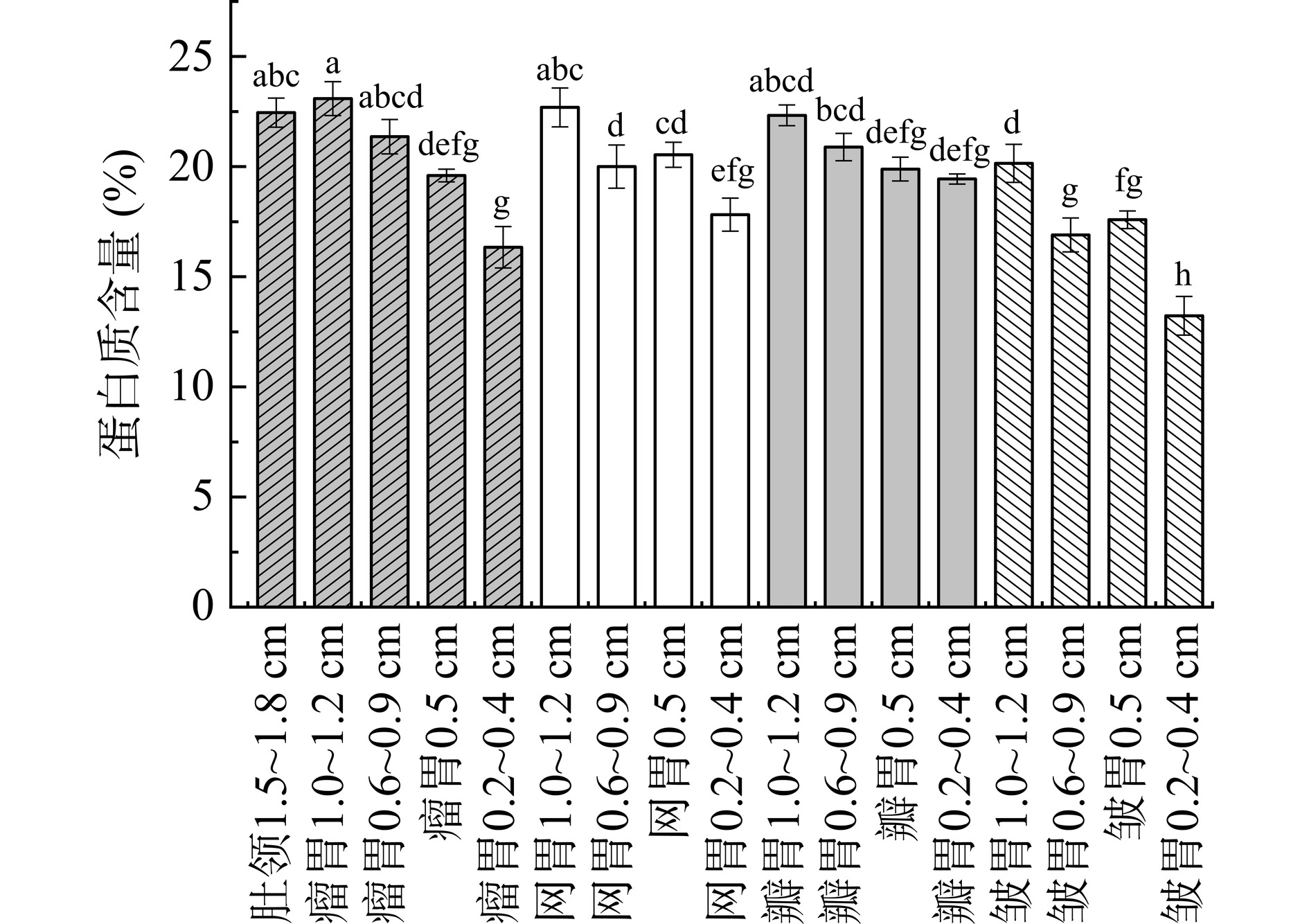

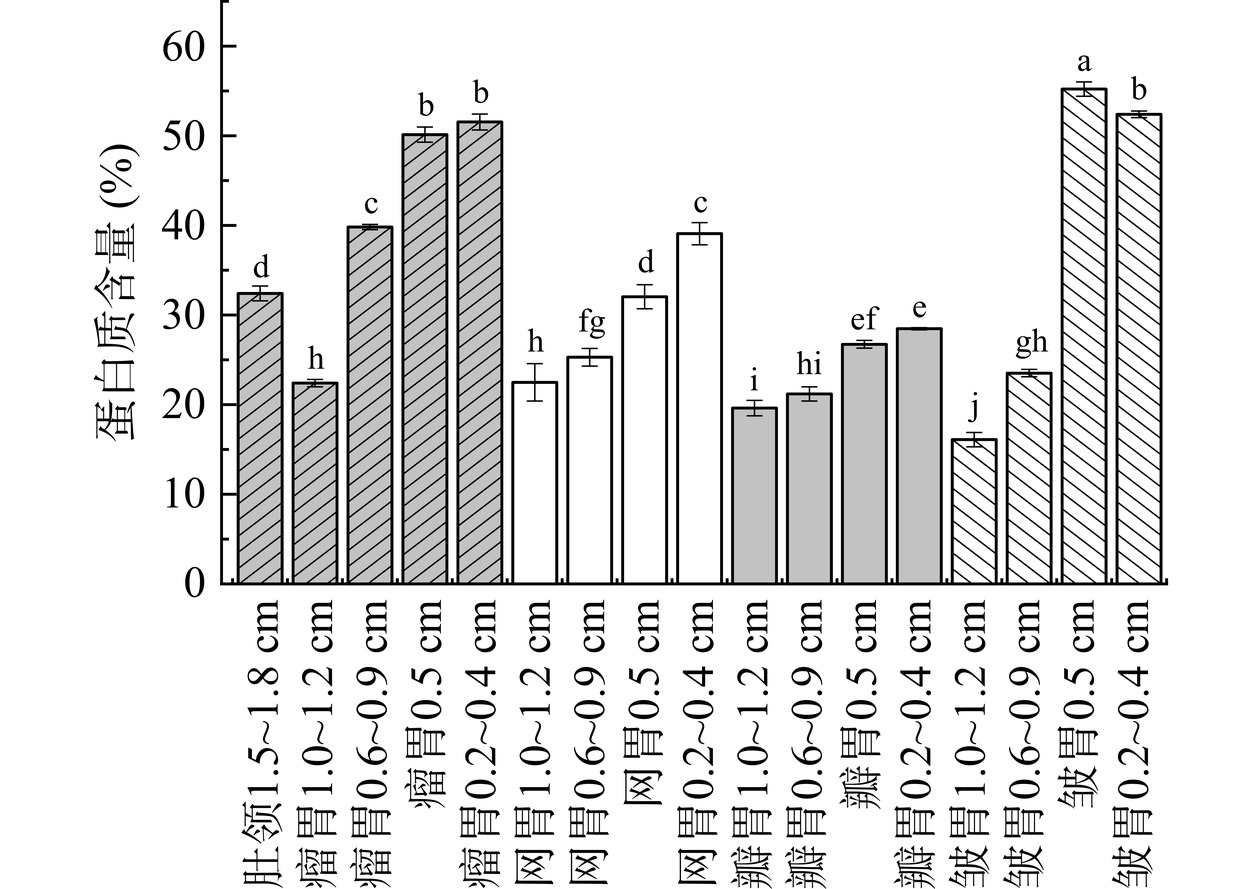

牦牛不同肌层厚度胃蛋白质含量变化如图1所示。瘤胃、网胃、瓣胃和皱胃不同肌层厚度呈现随着肌层厚度的降低,蛋白质含量逐渐降低,其中肚领1.5~1.8 cm与瘤胃1.0~1.2 cm、0.6~0.9 cm的蛋白质含量分别为22.45%、23.09%和21.36%差异不显著(P>0.05);网胃0.6~0.9 cm和0.5 cm差异不显著(P>0.05),瓣胃四个肌层厚度差异也不显著(P>0.05)。导致这一结果的原因,可能是因为每种胃的组织形态不同,肌层厚度不同、分子质量的大小不同会影响其蛋白质含量[25]。

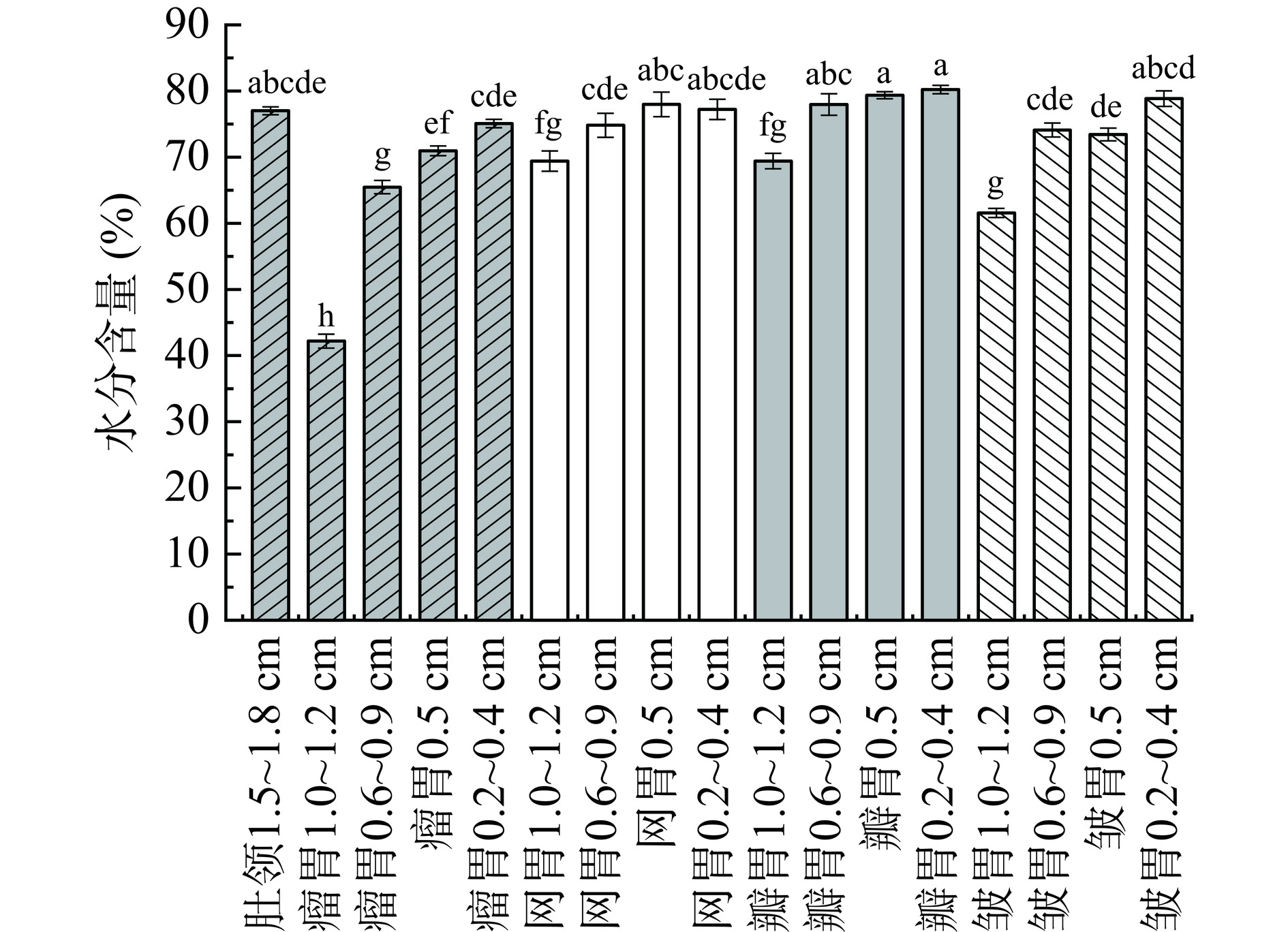

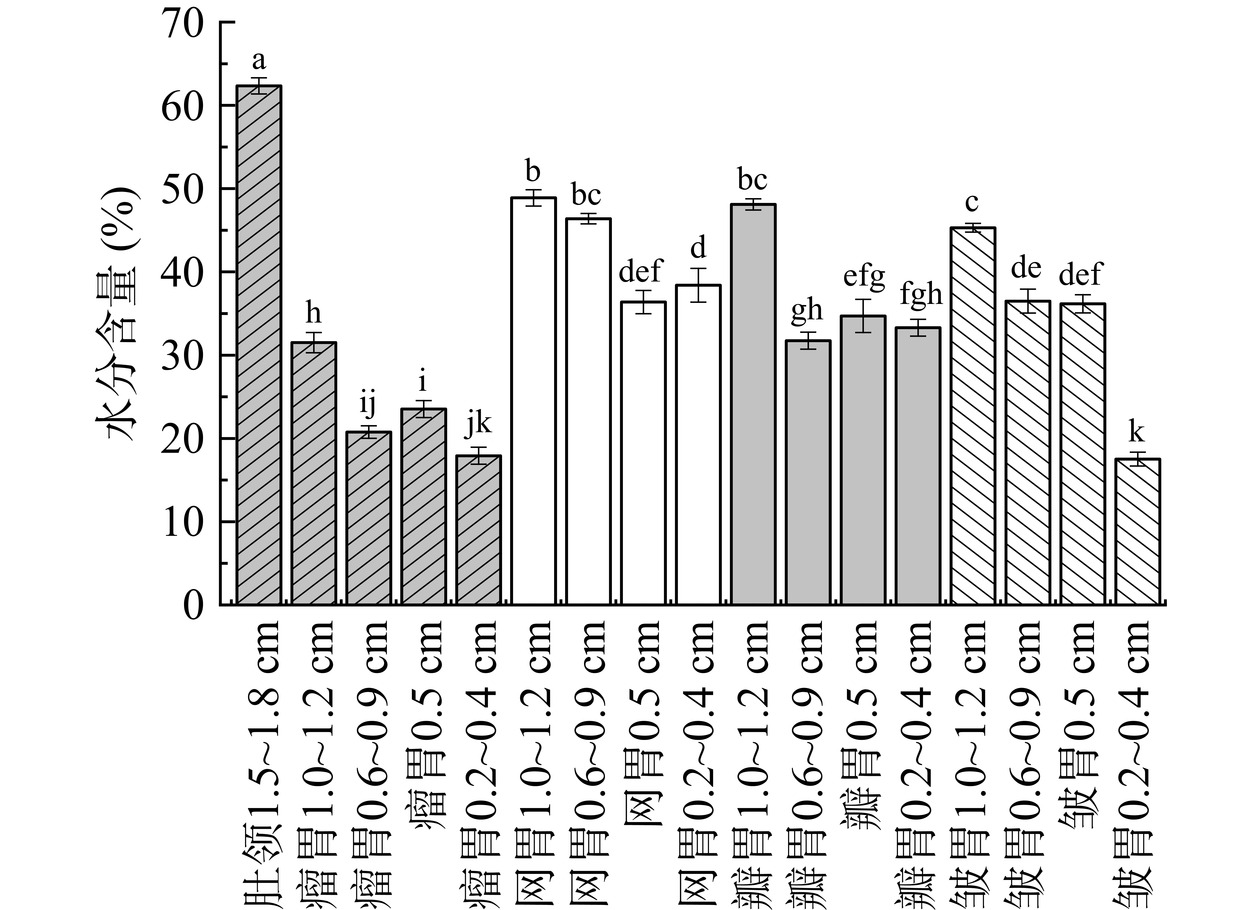

牦牛不同肌层厚度胃水分含量变化如图2所示。瘤胃不同肌层厚度呈现随着肌层厚度的降低,逐渐上升的趋势,瘤胃1.0~1.2 cm水分含量为42.19%,显著低于(P<0.05)其他样品;瓣胃0.5 cm、0.2~0.4 cm水分含量较高为79.36%和80.22%,这可能与瓣胃的生理结构具有过滤吸收水分的功能有关。

2.1.2 牦牛不同肌层厚度胃加工指标分析结果

2.1.2.1 蒸煮损失和离心损失

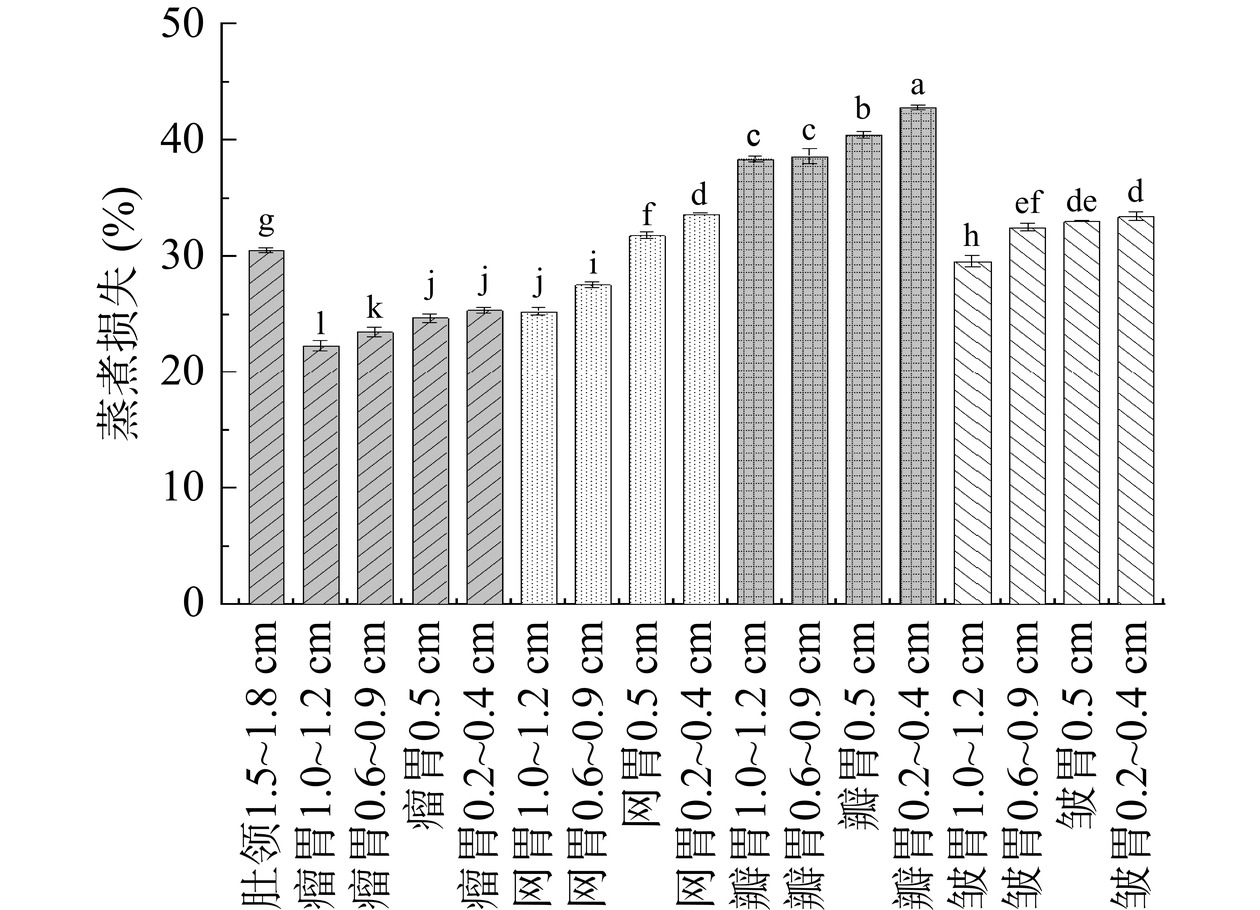

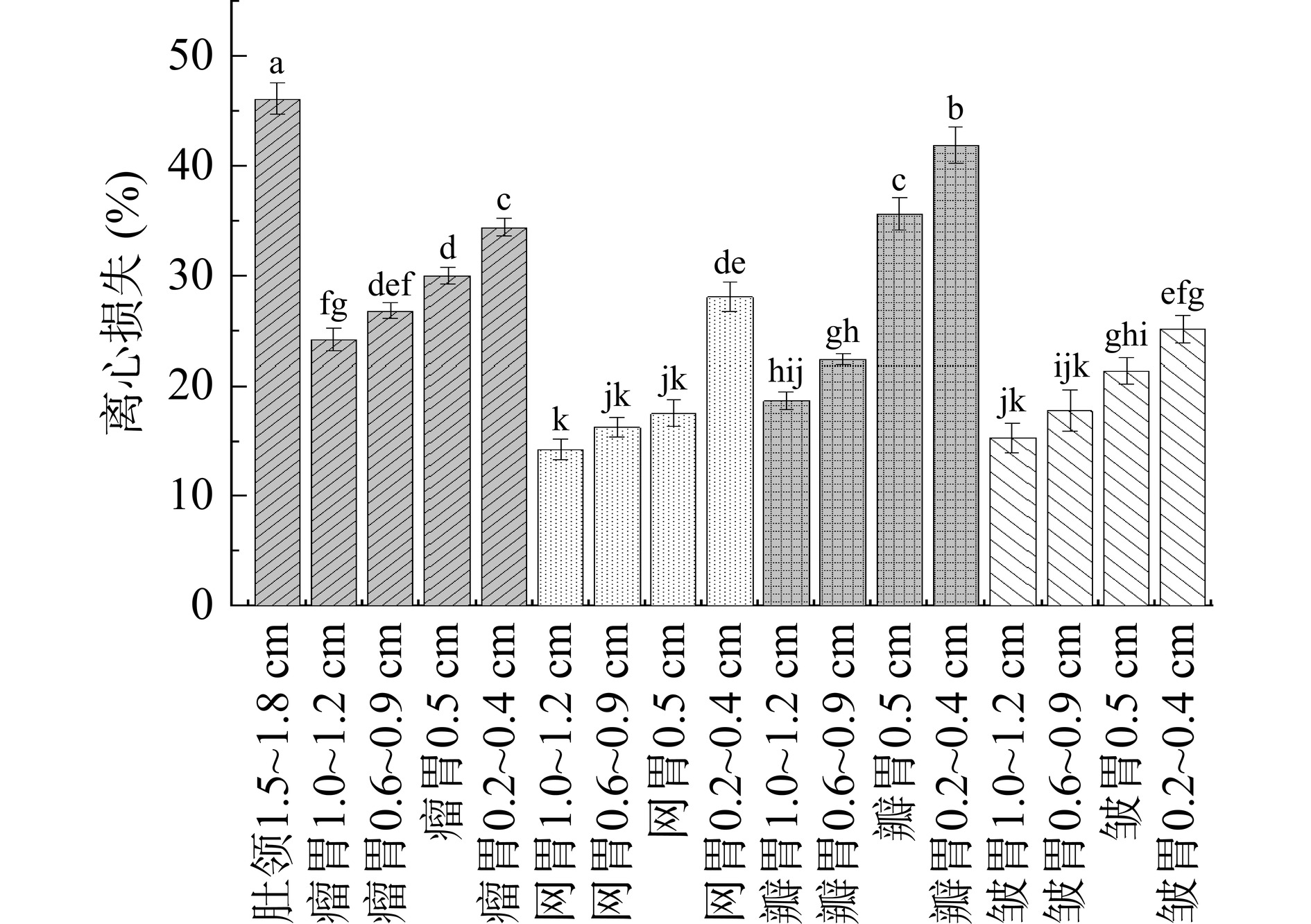

保水性指肌肉在贮藏和蒸煮过程中保持其原有水分的能力,蒸煮损失高低可直接反应原料肉保水性高低[26]。图3和图4反映了牦牛不同肌层厚度胃的保水性,发现牦牛瘤胃、网胃、瓣胃和皱胃的蒸煮损失和离心损失均随着厚度的降低,逐渐升高。其中肚领1.5~1.8 cm蒸煮损失和离心损失分别为30.56%和46.17%,显著高于瘤胃其他样品(P<0.05),其余四个胃呈现相同的趋势可能是和细胞大小与肌纤维间隙趋势相同有关,瓣胃的四个厚度显著高于其他样品(P<0.05),保水性较差。

2.1.2.2 乳化活性和乳化稳定性

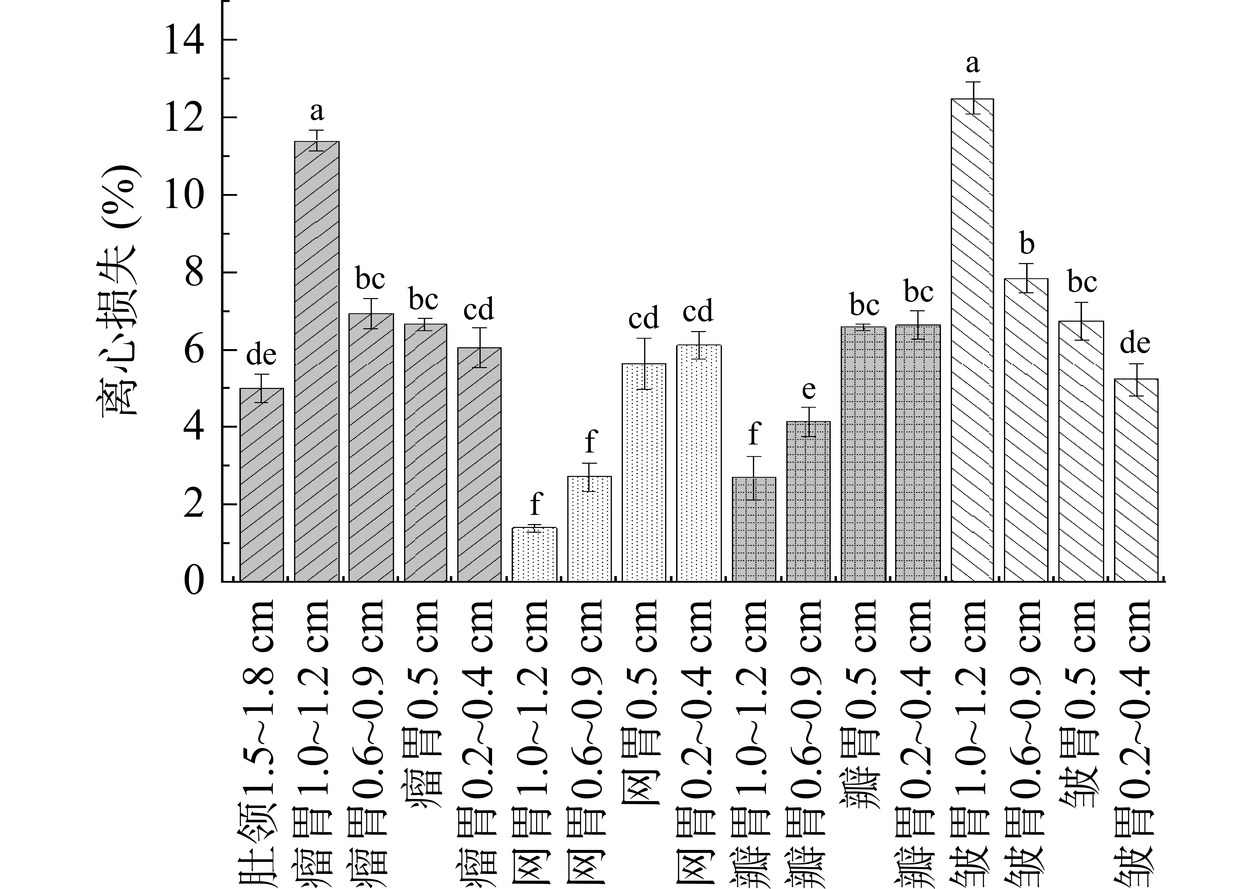

产品的稳定性取决于肌肉蛋白的乳化性,蛋白的乳化性主要包括乳化能力和乳化稳定性[27]。乳化能力越强,单位肌肉蛋白能够包裹的脂肪越多,从而稳定性越大,同时乳化同等数量脂肪的产品越稳定[28]。从表2可知,除肚领1.5~1.8 cm外,瘤胃、网胃、瓣胃和皱胃随着肌层厚度的降低,乳化活性逐渐降低,网胃1.0~1.2 cm和0.6~0.9 cm乳化活性为0.65和0.58,显著高于其他样品(P<0.05),肚领1.5~1.8 cm和瘤胃0.6~0.9 cm乳化活性接近,均为0.18。瓣胃和皱胃乳化稳定性均随着肌层厚度的降低,呈现下降趋势。网胃1.0 cm~1.2 cm和0.6 cm~0.9 cm乳化稳定性最好,显著高于其他样品(P<0.05)。王妍[12]发现瘤胃肚领和非肚领的乳化活性为0.18和0.20左右,乳化稳定性为14和16左右,与瘤胃研究结果一致。同时闫海鹏[29]研究发现,所提取的蛋白质的蛋白浓度相同时,乳化能力越大,乳化的油量越多,乳化稳定性越高,产品质量越好,货架期时间越长,结合本试验可知,牦牛肚领1.5~1.8 cm、瘤胃1.0~1.2 cm、瘤胃0.6~0.9 cm、网胃1.0~1.2 cm、网胃0.6~0.9 cm、瓣胃 1.0~1.2 cm、瓣胃0.6~0.9 cm、皱胃1.0~1.2 cm、皱胃0.6~0.9 cm乳化的油量相对于同一牦牛胃所产生的油量多,在加工中可更好的节约成本,同时产品质量好,货架期长。

表 2 牦牛胃不同肌层厚度乳化活性和乳化稳定性变化Table 2. Changes in emulsification activity and emulsification stability in yak stomach with different muscular layer thicknesses乳化活性(EA) 乳化稳定性(ES) 肚领1.5~1.8 cm 0.18±0.02d 13.31±0.30de 瘤胃1.0~1.2 cm 0.21±0.00c 12.73±0.47e 瘤胃0.6~0.9 cm 0.18±0.00de 15.99±1.01c 瘤胃0.5 cm 0.15±0.00f 6.47±0.07hi 瘤胃0.2~0.4 cm 0.13±0.01g 6.53±0.09ghi 网胃1.0~1.2 cm 0.65±0.02a 20.81±0.83b 网胃0.6~0.9 cm 0.58±0.00b 22.14±0.35a 网胃0.5 cm 0.10±0.00h 7.70±0.35g 网胃0.2~0.4 cm 0.05±0.00jk 9.64±0.01f 瓣胃1.0~1.2 cm 0.17±0.02def 14.29±1.58d 瓣胃0.6~0.9 cm 0.16±0.00ef 9.91±0.45f 瓣胃0.5 cm 0.10±0.00h 9.10±0.16f 瓣胃0.2~0.4 cm 0.06±0.00j 7.47±0.18gh 皱胃1.0~1.2 cm 0.08±0.00i 9.15±0.04f 皱胃0.6~0.9 cm 0.06±0.01j 5.71±0.26ij 皱胃0.5 cm 0.04±0.00kl 5.19±0.33j 皱胃0.2~0.4 cm 0.03±0.00l 5.57±0.65ij 注:表中小写字母表示不同肌层厚度差异显著(P<0.05),表3~表7同。 2.1.2.3 起泡能力和泡沫稳定性

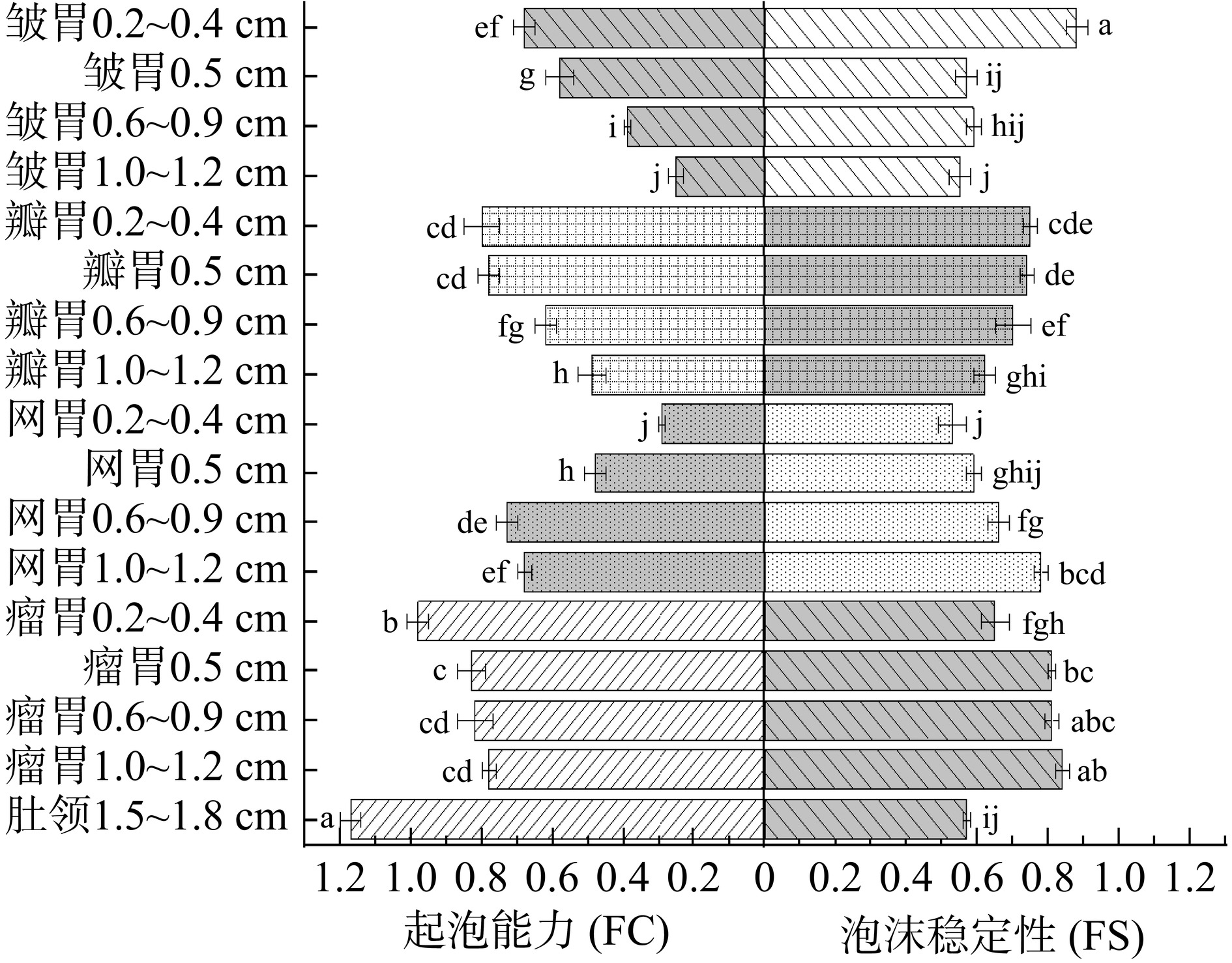

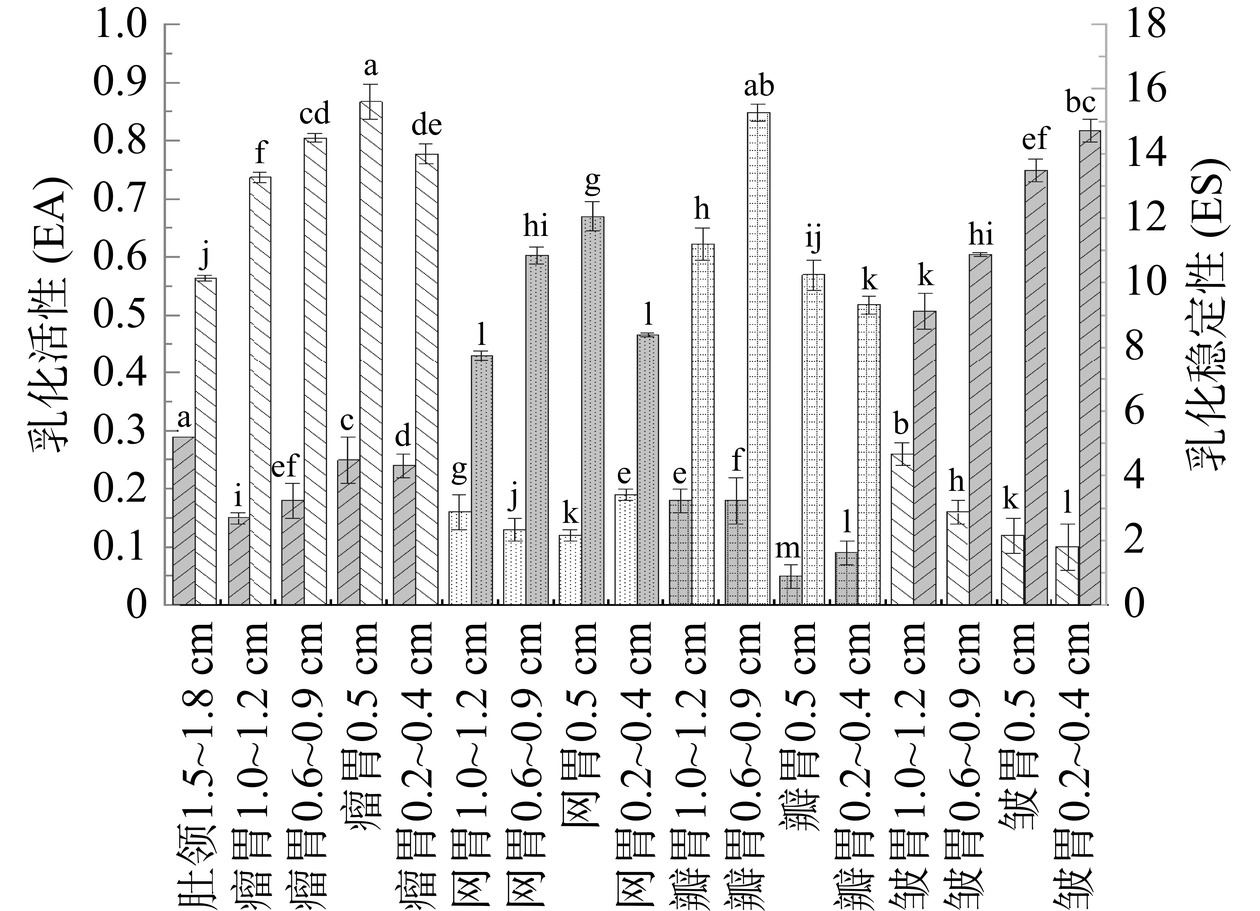

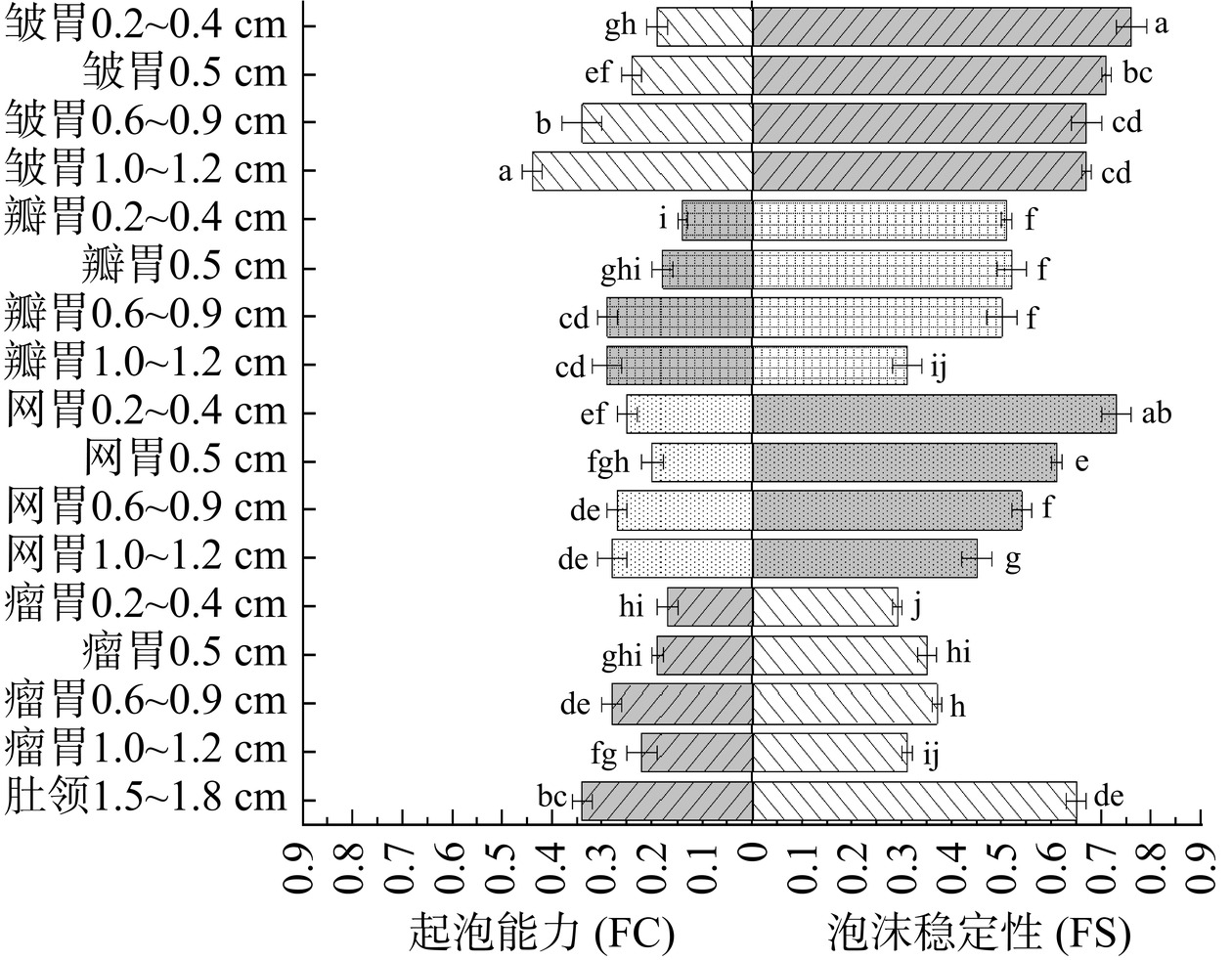

蛋白质的起泡性主要表现在蛋白质在打发的过程中,空气和水界面会被蛋白质分子吸附,形成具有弹性和延展性的蛋白质薄膜将空气包裹住所形成的泡沫[30]。图5左边反映了牦牛不同肌层厚度胃的起泡能力,图5右边反映了牦牛不同肌层厚度胃的泡沫稳定性。从图中可看出,肚领1.5~1.8 cm起泡能力为1.17,显著高于其他样本(P<0.05),其余瘤胃不同肌层厚度与和瓣胃、皱胃均随着厚度的降低,呈现逐渐升高的趋势,网胃则呈现相反趋势,网胃0.2~0.4 cm,起泡能力最弱,同时其泡沫稳定性较低。瘤胃肚领1.5~1.8 cm 和0.2~0.4 cm在瘤胃中,泡沫稳定性较低,瓣胃和皱胃呈现随着厚度的降低,泡沫稳定性逐渐升高的趋势,其中,皱胃0.2~0.4 cm 泡沫稳定性为0.88,显著高于其他样品(P<0.05),这个结果可能与蛋白泡沫的大小、表面电荷和不溶性颗粒有关[31]。

2.1.3 牦牛不同肌层厚度胃食用指标分析结果

2.1.3.1 牦牛不同肌层厚度胃色泽差异

肌肉颜色能直观的反映肉的品质,是影响消费者购买与否的主要因素之一[32]。牦牛不同肌层厚度胃的肉色值如表3所示,瘤胃五个不同肌层厚度L*值显著高于其他样本(P<0.05),说明瘤胃和网胃、瓣胃、皱胃相比,系水力较差。由于皱胃本身颜色偏于粉色且无黑膜,因此其四个厚度a*值显著高于其他样本(P<0.05),皱胃0.2~0.4 cm肌层较其他三个肌层厚度a*值较低,可能是因为皱胃又分为前部和后部,前部肌层厚度厚,颜色较红,后部肌层较薄,颜色较淡。整体看,不同厚度同种胃之间L*、a*、b*差异不显著(P>0.05),说明同一胃厚度对同一胃之间的色差值影响较小。罗天林[10]研究发现牦牛瘤胃L*值在65左右,a*值在12左右,b*值在20左右;牦牛皱胃L*值在45~60之间,a*值在20左右,b*值在15左右,牦牛瘤胃和皱胃色差值结果与本试验结果一致。

表 3 牦牛不同肌层厚度胃肉色值变化Table 3. Changes in gastric meat color values of yaks with different muscle layer thicknesses样品 L* a* b* △E 肚领1.5~1.8 cm 70.46±0.41abc 10.47±0.10gh 9.67±0.31e 71.89±0.38abc 瘤胃1.0~1.2 cm 71.24±1.74ab 14.80±0.56cdef 12.87±1.28cd 73.90±1.42ab 瘤胃0.6~0.9 cm 72.20±0.21a 14.42±0.15def 10.82±0.76de 74.42±0.20ab 瘤胃0.5 cm 72.21±0.76a 17.49±0.69c 16.77±2.18a 76.19±0.94a 瘤胃0.2~0.4 cm 72.92±1.36a 16.30±2.80cd 14.50±2.23abc 76.17±1.61a 网胃1.0~1.2 cm 67.29±1.25d 14.36±0.52def 8.47±0.12e 69.32±1.30de 网胃0.6~0.9 cm 68.76±0.43bcd 15.31±1.18cde 5.91±2.08f 70.55±0.69bcd 网胃0.5 cm 66.87±1.39d 13.00±2.17efg 3.80±1.15fg 67.99±1.73e 网胃0.2~0.4 cm 67.54±1.58cd 12.28±1.28fg 3.57±0.83fg 68.50±2.06e 瓣胃1.0~1.2 cm 63.29±1.61e 7.56±1.40i 1.68±0.77g 63.23±1.79f 瓣胃0.6~0.9 cm 61.95±1.61ef 7.09±1.74i 1.35±0.20g 62.71±1.76f 瓣胃0.5 cm 59.26±1.67fgh 6.08±1.03i 1.65±0.31g 59.61±1.59g 瓣胃0.2~0.4 cm 61.06±1.15efg 8.31±1.77hi 1.34±1.06g 61.66±1.01fg 皱胃1.0~1.2 cm 58.85±2.42gh 32.66±2.02a 15.23±2.09abc 69.04±2.70de 皱胃0.6~0.9 cm 59.53±0.97fgh 31.83±1.03b 15.05±0.54abc 69.11±1.66de 皱胃0.5 cm 58.07±1.38h 29.48±0.69ab 15.91±0.09ab 67.80±0.57e 皱胃0.2~0.4 cm 58.43±1.34gh 17.59±1.03c 13.55±0.99bc 62.85±1.52f 2.1.3.2 牦牛不同肌层厚度胃剪切力和质构差异

剪切力既能客观反映出肉品的嫩度,又是质构的主要评价指标[33]。牦牛不同肌层厚度的剪切力值如表4所示,除肚领1.5~1.8 cm外,瘤胃、网胃、瓣胃和皱胃剪切力值均随着厚度的降低,逐渐减小。瓣胃不同肌层厚度剪切力值显著低于(P<0.05)其他样品,可能是因为随着厚度的降低,肌肉中结缔组织较少,导致肉质越嫩[34]。王复龙等[35]研究发现,瘤胃的剪切力值在14 kg左右,网胃的剪切力值在10 kg左右,与本试验结果保持一致。

表 4 牦牛不同肌层厚度胃剪切力和质构变化Table 4. Changes in gastric shear force and texture of yaks with different muscle layer thicknesses剪切力(kg) 硬度(kg) 弹力 内聚性 胶着性(kg) 咀嚼性(mJ) 肚领1.5~1.8 cm 9.74±0.40d 3.10±0.08ef 0.50±0.03cd 0.78±0.02bcd 2.24±0.16fg 1859.55±254.19d 瘤胃1.0~1.2 cm 14.22±0.39a 1.84±0.24h 0.33±0.01ef 0.74±0.03cde 1.34±0.12hi 1181.79±151.11ef 瘤胃0.6~0.9 cm 13.27±1.16ab 5.70±0.46b 0.46±0.02d 0.78±0.08bcde 3.12±0.58de 1285.92±36.81e 瘤胃0.5 cm 10.39±0.50d 5.10±1.09bc 0.50±0.04cd 0.77±0.07bcde 3.91±0.90bc 2581.33±108.15c 瘤胃0.2~0.4 cm 9.70±0.33d 8.43±0.44a 0.52±0.03bcd 0.87±0.07ab 6.47±0.69a 5205.83±14.65a 网胃1.0~1.2 cm 13.41±0.97ab 2.14±0.19gh 0.36±0.01e 0.86±0.00abc 2.45±0.38ef 2499.44±235.59c 网胃0.6~0.9 cm 13.23±0.87ab 3.76±0.46de 0.52±0.03bcd 0.85±0.14abc 3.52±0.36cd 2869.78±99.45c 网胃0.5 cm 11.56±0.09c 3.99±0.55de 0.57±0.03bc 0.85±0.03abc 3.36±0.39cd 4046.57±61.78b 网胃0.2~0.4 cm 8.10±0.29e 4.50±0.38cd 0.58±0.05b 0.82±0.07abcd 4.16±0.19b 4452.53±762.23b 瓣胃1.0~1.2 cm 9.52±0.26d 2.14±0.24gh 0.46±0.02d 0.93±0.01a 1.67±0.26fghi 742.13±40.04ghi 瓣胃0.6~0.9 cm 8.42±0.15e 1.82±0.14h 0.38±0.03e 0.71±0.06de 1.62±0.29ghi 530.58±5.84hi 瓣胃0.5 cm 8.28±0.25e 1.64±0.13h 0.33±0.02ef 0.76±0.07bcde 1.38±0.08hi 288.33±48.91i 瓣胃0.2~0.4 cm 7.36±0.27e 1.82±0.21h 0.34±0.02ef 0.66±0.06ef 1.44±0.09hi 437.85±39.99hi 皱胃1.0~1.2 cm 13.10±0.18b 2.85±0.48fg 0.81±0.02a 0.75±0.06bcde 2.05±0.26fg 1097.91±38.02efg 皱胃0.6~0.9 cm 12.58±0.34bc 2.42±0.03fgh 0.37±0.05e 0.57±0.03f 1.85±0.19fgh 762.30±23.14fgh 皱胃0.5 cm 9.57±0.12d 2.15±0.20gh 0.27±0.03fg 0.35±0.05g 1.32±0.26hi 730.00±105.43ghi 皱胃0.2~0.4 cm 9.51±0.26d 1.82±0.66h 0.25±0.05g 0.25±0.03g 1.06±0.04i 753.89±39.38fgh 质地剖面分析(texture Profile analysis,TPA)法是一种常见的食品分析方法[36],在肉制品中,质构可直接反映肉品品质,对肉品的开发和加工有重要影响[37]。瘤胃0.2~0.4 cm硬度最高,为8.43 kg,显著高于其他样品(P<0.05),瓣胃四个肌层厚度硬度值均较低。张晨等[38]研究发现非肚领(Ⅰ)硬度值为9290.7 g,非肚领(Ⅱ)硬度值为6816 g,与本研究趋势一致,导致这一趋势,可能是由于不同厚度胃的蛋白质组成和含量不同。弹力是反映新鲜度的指标,样品含水率越高,弹力越大。弹力趋势和硬度趋势相同,除肚领1.5~1.8 cm外,瘤胃和网胃的弹力随着厚度的降低逐渐升高,而瓣胃和皱胃则相反。其中,皱胃肌层厚度为1.0~1.2 cm时,弹力为0.81,显著高于其他样品(P<0.05),这一结果可能是由于结缔组织中的弹性蛋白和胶原蛋白含量不同所影响的。瘤胃、网胃呈现随着厚度的降低,内聚性逐渐增加趋势,瓣胃和皱胃则呈现相反趋势,且四个胃的不同肌层厚度差异不显著(P>0.05)。张晨等[38]发现瘤胃(Ⅰ)的内聚性显著高于其他样品,这与本试验结果相一致。四个胃胶着性的趋势和内聚性趋势相同。其中,瘤胃0.2~0.4 cm胶着性为6.47 kg,显著高于其他样品(P<0.05),皱胃0.2~0.4 cm时为1.06 kg显著低于(P<0.05)其他样品。瘤胃和网胃随着肌层厚度的降低,呈现逐渐上升趋势,其中瘤胃0.2~0.4 cm咀嚼性最高。瓣胃和皱胃咀嚼性随着厚度的降低,呈现逐渐降低趋势,且瓣胃四个肌层厚度的咀嚼性显著低于(P<0.05)其他样品,同时四个肌层厚度之间咀嚼性差异不显著(P>0.05)导致牦牛胃不同肌层厚度TPA特性不同的主要原因是肌肉中的结缔组织的数量、蛋白质的溶解度、肌肉纤维的组成和收缩状态以及僵肌中蛋白质水解程度的不同[39]。

2.2 烤制牦牛胃不同肌层厚度品质指标分析结果

2.2.1 烤制牦牛胃不同肌层厚度理化指标分析结果

图6表示经过烤制加工后牦牛胃不同肌层厚度水分含量。从图中可看出,随着厚度的逐渐降低,水分含量基本呈现逐渐降低的趋势,其中肚领1.5~1.8 cm水分含量为62.34%,显著高于(P<0.05)其他样品,瘤胃和皱胃0.2~0.4 cm水分含量显著低于(P<0.05)其他样品,导致这一原因可能是因为随着热处理温度的升高,样品的肌动蛋白和肌联蛋白会发生横向收缩,从而导致大量水分流失[40]。

图7分别表示经过烤制加工后牦牛胃不同肌层厚度蛋白质含量,从图中可看出,皱胃0.5 cm蛋白质含量显著高于(P<0.05)其他样品,为55.22%,皱胃1.0~1.2 cm显著低于(P<0.05)其他样品,为16.10%,造成此原因可能是因为经过烤制加工后的样品由于蛋白质发生变性,从而影响蛋白质含量。

2.2.2 烤制牦牛胃不同肌层厚度加工指标分析结果

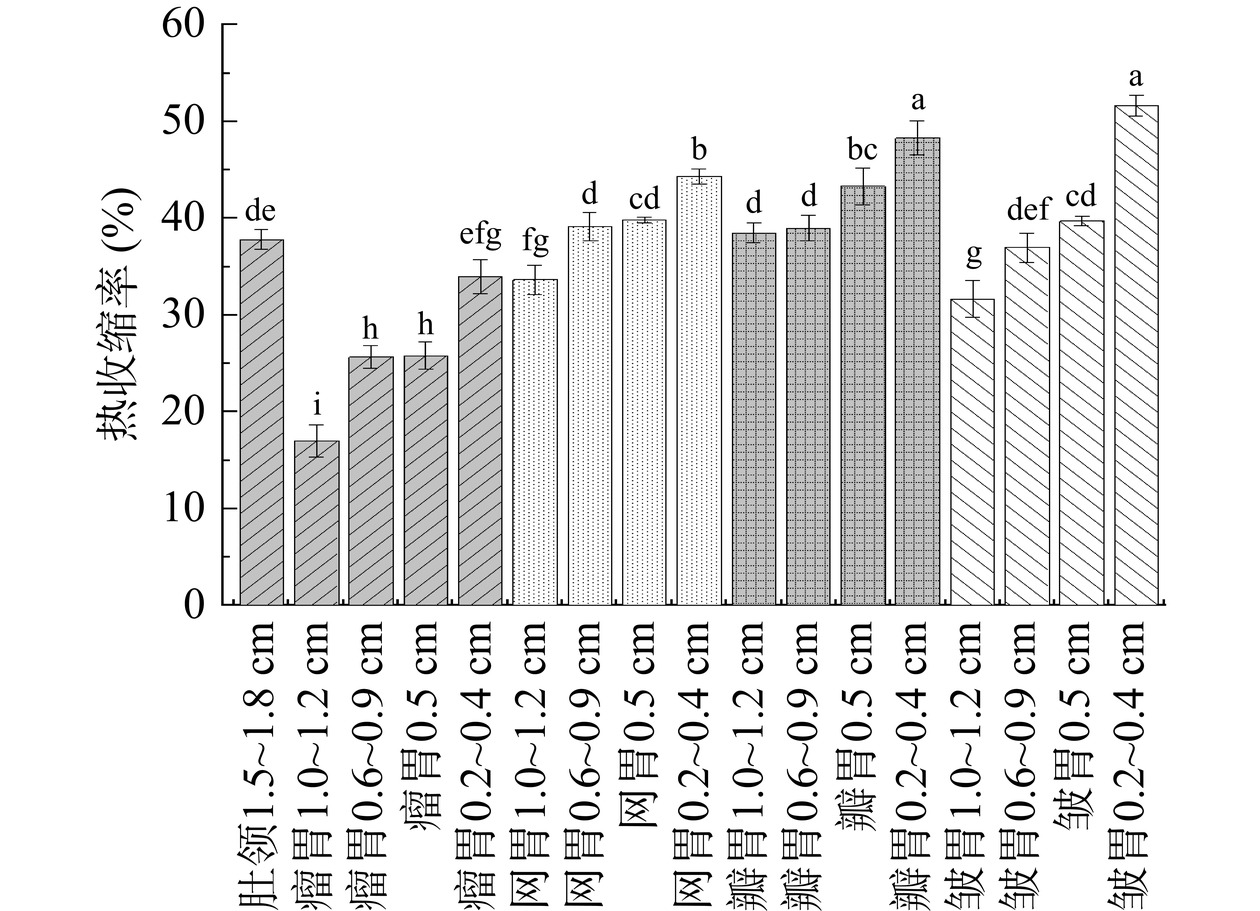

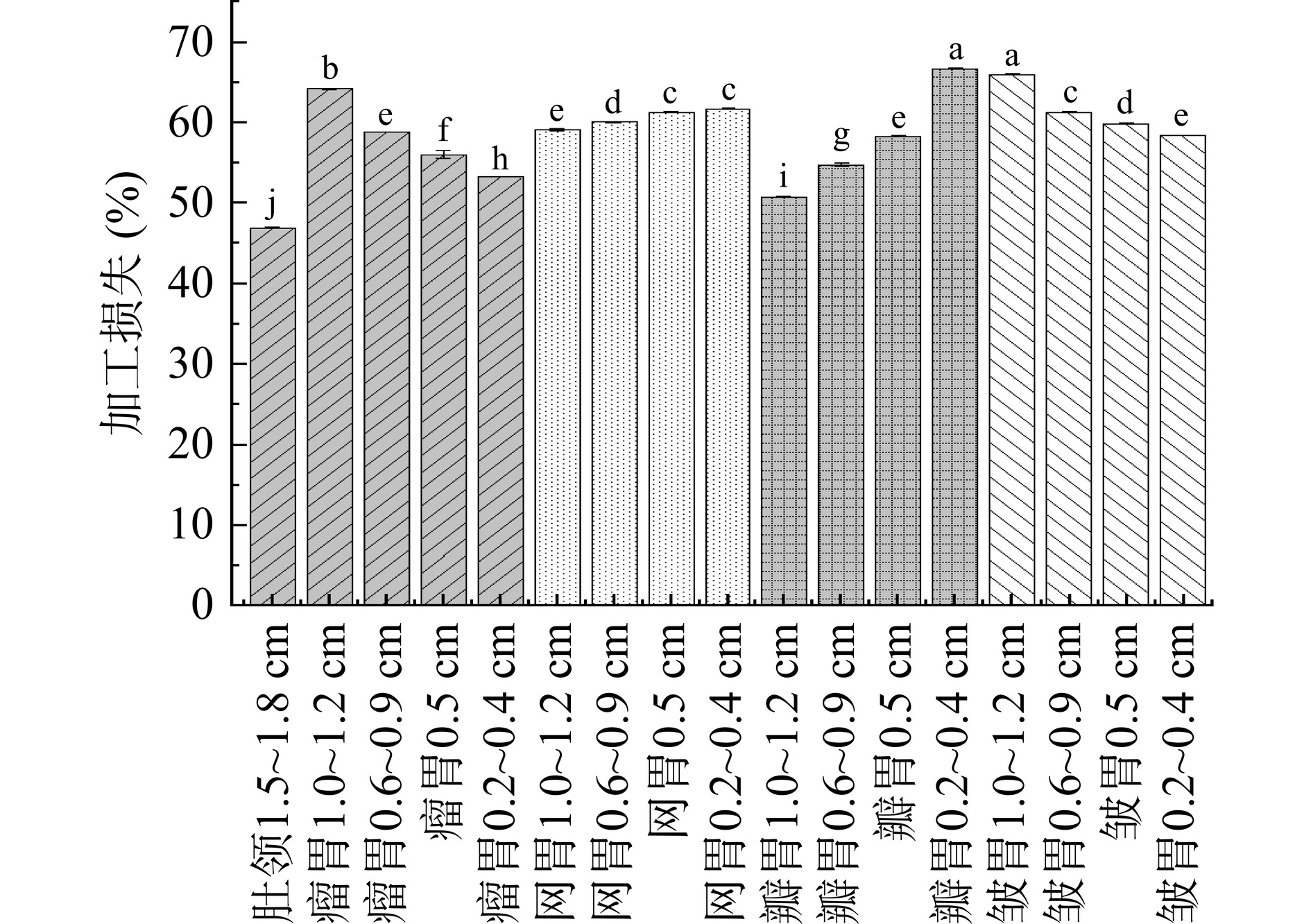

从图8可知,经过烤制加工后牦牛不同肌层厚度胃加工品质存在差异。通过热收缩率指标可知,瓣胃0.2~0.4 cm和皱胃0.2~0.4 cm显著高于(P<0.05)其他样品,瘤胃中除肚领1.5~1.8 cm外,其他肌层厚度同网胃、瓣胃和皱胃均随着厚度的降低呈逐渐升高趋势。说明,经过烤制加工后,厚度越薄的样品,热收缩越明显。

图9、图10分别表示经过烤制加工后牦牛胃不同肌层厚度加工损失和离心损失,从图中可看出,瘤胃中,肚领1.5~1.8 cm加工损失和离心损失最小,网胃和瓣胃随着肌层厚度的降低呈逐渐升高趋势,瘤胃和皱胃呈降低趋势,可能是因为在烤制加工时,肉块在受到高温处理后,大量内容物流出,后因内外渗透压差等原因,部分水分残留在纤维间隙,从而导致加工损失较小。

从图11可知,肚领1.5~1.8 cm乳化活性显著高于(P<0.05)其他样品,瘤胃随着厚度的降低,乳化活性呈逐渐升高趋势,瓣胃和皱胃呈逐渐降低趋势,瘤胃0.5 cm的乳化稳定性显著高于(P<0.05)其他样品,皱胃四个肌层厚度乳化活性和乳化稳定性高于原料肉,原因可能是经过烤制加工后,皱胃结构展开,较多的亲油和亲水基团暴露,使油水发生了较好的交联作用,进而提高了乳化活性[41],有利于乳化稳定[42]。

图12表明,烤制牦牛不同肌层厚度胃起泡特性差异。蛋白质的起泡能力与其产品口感等相关[43]。随着厚度的降低,瘤胃、网胃、瓣胃和皱胃起泡能力整体呈现逐渐降低趋势,可能是因为烤制时样品表面的受热程度较高,经烤制加工后的样品的肌球蛋白含量减少,空间结构变化加剧,导致蛋白质分子之间的化学作用力以及氨基与羧基之间形成氢键的能力变弱,分子间的界面特性与扩散速率受到影响,继而导致蛋白质的泡沫形成能力减弱[44]。皱胃0.2~0.4 cm泡沫稳定性显著高于其他样品(P<0.05),瘤胃0.2~0.4 cm泡沫稳定性显著低于(P<0.05)其他样品。随着厚度的降低,瘤胃、网胃、瓣胃和皱胃起泡能力整体呈现逐渐降低趋势;随着厚度的降低,网胃、瓣胃和皱胃的泡沫稳定性呈现逐渐升高趋势。

2.2.3 烤制牦牛不同肌层厚度胃食用指标分析结果

2.2.3.1 烤制牦牛不同肌层厚度胃色泽差异

表5表示烤制牦牛胃不同肌层厚度对色差的影响,肚领1.5~1.8 cm的L*、b*和△E值显著高于(P<0.05)其他样品。皱胃1.0~1.2 cm的a*值显著高于(P<0.05)其他样品,且皱胃四个肌层厚度的a*值均显著高于其他样品,因为皱胃原料肉a*值高,经过烤制加工后皱胃比其他胃更亮,a*值更高。同种胃不同肌层厚度之间L*、a*、b*差异基本不显著(P>0.05),说明经过烤制加工,牦牛胃不同肌层厚度对色差的影响较小。

表 5 烤制加工对不同肌层厚度牦牛肉色的影响Table 5. Effect of baking processing on the color of yak meat with different muscle layer thicknessesL* a* b* △E 肚领1.5~1.8 cm 58.72±1.05a 9.11±0.30h 28.05±1.72a 65.72±1.41a 瘤胃1.0~1.2 cm 34.19±0.58hi 12.15±0.76g 10.48±1.06gh 37.78±0.37i 瘤胃0.6~0.9 cm 32.99±0.64ij 11.85±0.91g 11.27±1.01fg 36.84±0.85i 瘤胃0.5 cm 32.93±0.65ij 8.93±0.66h 15.11±0.73de 37.32±0.44i 瘤胃0.2~0.4 cm 35.39±0.03h 7.99±0.83h 13.68±2.07e 39.01±0.60hi 网胃1.0~1.2 cm 54.77±3.02b 15.80±1.05de 19.79±1.46c 60.35±3.25c 网胃0.6~0.9 cm 48.72±0.51d 15.50±0.81def 22.48±1.07b 55.86±0.74de 网胃0.5 cm 46.54±0.77e 13.96±0.37f 19.66±1.13c 52.42±0.78f 网胃0.2~0.4 cm 41.80±0.25g 11.44±0.52g 17.02±0.83d 46.56±0.37g 瓣胃1.0~1.2 cm 57.64±0.40a 19.42±1.08c 16.87±0.35d 63.13±0.09b 瓣胃0.6~0.9 cm 54.40±1.20c 16.17±0.28d 16.74±0.32d 58.42±1.15d 瓣胃0.5 cm 49.33±0.59cd 16.01±0.71de 14.89±1.14de 53.97±0.67ef 瓣胃0.2~0.4 cm 44.10±0.62f 14.23±1.15ef 13.48±0.73ef 48.27±0.99g 皱胃1.0~1.2 cm 29.26±0.49k 24.21±1.34a 3.84±0.60j 38.19±0.93hi 皱胃0.6~0.9 cm 31.43±1.28j 22.14±1.07b 4.52±1.01j 38.74±0.65hi 皱胃0.5 cm 31.27±0.16jk 22.16±1.15b 6.90±0.43i 38.96±0.62hi 皱胃0.2~0.4 cm 33.76±0.86hi 20.29±0.83c 8.47±1.19hi 40.30±1.05h 2.2.3.2 烤制牦牛不同肌层厚度胃剪切力和质构差异

表6表示烤制牦牛胃不同肌层厚度对剪切力值和质构的影响,网胃0.2~0.4 cm的剪切力值、弹力、内聚性、咀嚼性显著高于(P<0.05)其他样品,瘤胃0.5 cm的硬度、内聚性、胶着性显著高于(P<0.05)其他样品。除肚领1.5~1.8 cm外,瘤胃、网胃、瓣胃的剪切力值随着厚度的降低而逐渐升高,说明厚度越厚,烤制后的肉品越嫩,皱胃的剪切力值呈现先上升后下降的趋势,皱胃0.2~0.4 cm剪切力较低,与其组织结构有关,皱胃0.2~0.4 cm肌层较薄,褶皱较少,且经过烤制加工后,使其变脆,因此其剪切力值、弹力值较低。

表 6 烤制加工对不同肌层厚度牦牛剪切力和质构的影响Table 6. Effect of baking processing on shear force and texture of yaks with different muscle layer thicknesses剪切力(kg) 硬度(kg) 弹力 内聚性 胶着性(kg) 咀嚼性(mJ) 肚领1.5~1.8 cm 10.63±0.23b 4.07±0.63c 0.33±0.03cde 0.81±0.04abc 3.24±0.75c 2337.73±482.90ab 瘤胃1.0~1.2 cm 7.43±0.20ef 1.76±0.03ghi 0.27±0.03fg 0.64±0.03g 1.07±0.01hij 60.00±5.16f 瘤胃0.6~0.9 cm 7.75±0.18e 1.33±0.15ij 0.29±0.02def 0.68±0.07efg 1.20±0.06ghij 62.27±10.68f 瘤胃0.5 cm 10.46±0.17b 7.43±0.33a 0.33±0.03cde 0.82±0.00ab 4.87±0.55a 1639.67±152.05cd 瘤胃0.2~0.4 cm 10.26±0.09bc 6.58±0.31b 0.28±0.02ef 0.69±0.03defg 4.28±0.43ab 253.53±31.00f 网胃1.0~1.2 cm 6.89±0.19g 2.47±0.23ef 0.40±0.03ab 0.67±0.02efg 1.72±0.03efg 124.50±12.46f 网胃0.6~0.9 cm 8.49±0.43d 2.84±0.11de 0.41±0.01a 0.78±0.05bcd 2.20±0.14de 1950.40±136.94bc 网胃0.5 cm 10.06±0.02c 2.12±0.12fgh 0.34±0.02cd 0.83±0.01ab 2.14±0.27de 1244.67±128.85de 网胃0.2~0.4 cm 11.50±0.17a 6.08±0.39b 0.22±0.06gh 0.88±0.00a 4.17±0.09b 2609.80±134.46a 瓣胃1.0~1.2 cm 4.30±0.15j 0.72±0.025k 0.42±0.01a 0.74±0.01cde 0.60±0.03j 131.03±23.10f 瓣胃0.6~0.9 cm 6.35±0.10h 2.25±0.37efg 0.35±0.01bc 0.86±0.02a 1.84±0.18ef 1704.10±229.67c 瓣胃0.5 cm 7.27±0.08f 1.52±0.40hij 0.34±0.04cd 0.82±0.02abc 1.51±0.23fgh 899.87±28.79e 瓣胃0.2~0.4 cm 8.32±0.14d 1.04±0.13jk 0.34±0.00cd 0.82±0.02abc 0.80±0.15ij 43.63±1.23f 皱胃1.0~1.2 cm 4.47±0.16j 1.06±0.15jk 0.35±0.04bc 0.66±0.02fg 0.60±0.09j 405.93±20.12f 皱胃0.6~0.9 cm 7.30±0.15f 2.64±0.30def 0.38±0.00abc 0.72±0.06def 1.75±0.35efg 1614.77±316.88cd 皱胃0.5 cm 6.32±0.19hi 3.24±0.29d 0.25±0.04fg 0.72±0.07def 2.65±0.14cd 2537.70±456.44a 皱胃0.2~0.4 cm 5.96±0.03i 1.44±0.28ij 0.19±0.01h 0.62±0.07g 1.21±0.32ghi 834.00±97.96e 2.2.4 烤制牦牛不同肌层厚度胃感官评价结果

9位感官评价员对17个烤制加工后牦牛胃不同肌层厚度感官评价结果见表7。由表7可知,17个牦牛胃不同肌层厚度的外观、色泽、嫩度、多汁性、风味之间都具有显著性差异(P<0.05)。其中经过烤制加工后瓣胃0.5 cm和瓣胃0.2~0.4 cm外观都较差;肚领1.5~1.8 cm的风味、多汁性显著高于(P<0.05)其他样品;瘤胃、网胃、瓣胃和皱胃0.5 cm、0.2~0.4 cm的嫩度、多汁性、风味都较差。9位感官评价员普遍认为肚领1.5~1.8 cm、网胃1.0~1.2 cm、瓣胃1.0~1.2 cm具有显著高于其他样品的整体可接受性,瘤胃0.5 cm、瘤胃0.2~0.4 cm、网胃0.2~0.4 cm、瓣胃0.2~0.4 cm、皱胃0.5 cm、皱胃0.2~0.4 cm被认为最令人难以接受(P<0.05)。

表 7 烤制加工对牦牛胃不同肌层厚度感官评价的影响Table 7. Effect of baking processing on sensory evaluation of yak stomach with different muscle layer thicknesses外观 色泽 嫩度 多汁性 风味 整体可接受性 肚领1.5~1.8 cm 8.20±1.96abcd 8.37±1.74abc 8.43±0.87abc 8.63±0.82a 9.09±1.08a 9.37±0.10a 瘤胃1.0~1.2 cm 8.03±0.89abcd 8.20±0.98bc 5.38±0.71de 5.04±1.02c 5.52±1.74e 6.15±1.36defg 瘤胃0.6~0.9 cm 8.28±1.91abc 8.17±1.78bc 5.40±0.73de 5.39±1.69c 5.60±1.09e 6.25±1.15defg 瘤胃0.5 cm 8.11±1.19abcd 8.04±1.56bc 5.53±0.76de 5.32±1.79c 5.42±1.21e 6.14±1.62defg 瘤胃0.2~0.4 cm 7.34±1.06de 7.87±1.80bc 5.57±1.64d 5.38±1.00c 5.61±0.80e 6.07±1.45efg 网胃1.0~1.2 cm 8.14±0.90abcd 8.26±0.94bc 8.76±1.56a 8.53±1.51a 8.33±0.58abc 8.98±0.71ab 网胃0.6~0.9 cm 8.39±1.27ab 8.35±0.86abc 8.08±1.63abc 7.92±1.02ab 8.78±0.67ab 8.65±0.58abc 网胃0.5 cm 8.07±1.96abcd 8.00±1.13bc 7.87±1.76bc 5.72±0.53c 7.76±1.66cd 7.25±0.38cdef 网胃0.2~0.4 cm 7.28±1.48de 8.07±1.06bc 4.98±1.71de 5.25±1.66c 5.49±0.63e 5.73±1.29fg 瓣胃1.0~1.2 cm 8.10±0.72abcd 9.04±0.36a 8.74±1.58ab 8.49±0.95a 7.56±1.12cd 8.39±0.35abc 瓣胃0.6~0.9 cm 8.21±1.71abcd 8.36±1.47abc 7.66±0.48c 7.53±1.04b 7.66±1.47cd 8.06±1.18abc 瓣胃0.5 cm 7.06±1.63e 7.99±1.62bc 5.53±1.01de 4.99±1.09c 5.55±1.04e 6.15±0.55defg 瓣胃0.2~0.4 cm 7.00±0.79e 7.61±1.23c 5.59±0.69d 7.71±0.64ab 5.92±1.38e 5.84±1.05fg 皱胃1.0~1.2 cm 8.66±1.56a 9.06±0.75a 8.02±0.79abc 7.95±1.73ab 7.84±1.09bcd 7.59±1.13bcdef 皱胃0.6~0.9 cm 8.07±1.46abcd 8.25±0.68bc 7.96±1.46abc 7.86±1.77ab 7.09±1.20d 7.74±1.61abcd 皱胃0.5 cm 7.68±1.49bcde 8.20±1.71bc 4.66±1.02e 5.58±1.65c 5.27±0.69e 5.92±1.04fg 皱胃0.2~0.4 cm 7.35±1.59cde 8.61±1.17ab 5.05±0.59de 4.84±1.79c 5.42±1.53e 4.66±0.61g 2.3 烤制牦牛不同肌层厚度胃适宜性结果分析

2.3.1 烤制加工牦牛胃不同肌层厚度适宜性评价指标确定

表8为烤制加工牦牛不同肌层厚度胃品质指标主成分结果。通常选取特征根>1的成分与累计贡献率≥80%的主成分数为研究对象[45]。从表8可看出,前5个主成分的方差累计贡献率达到86.511%,因此,选择前5个主成分。

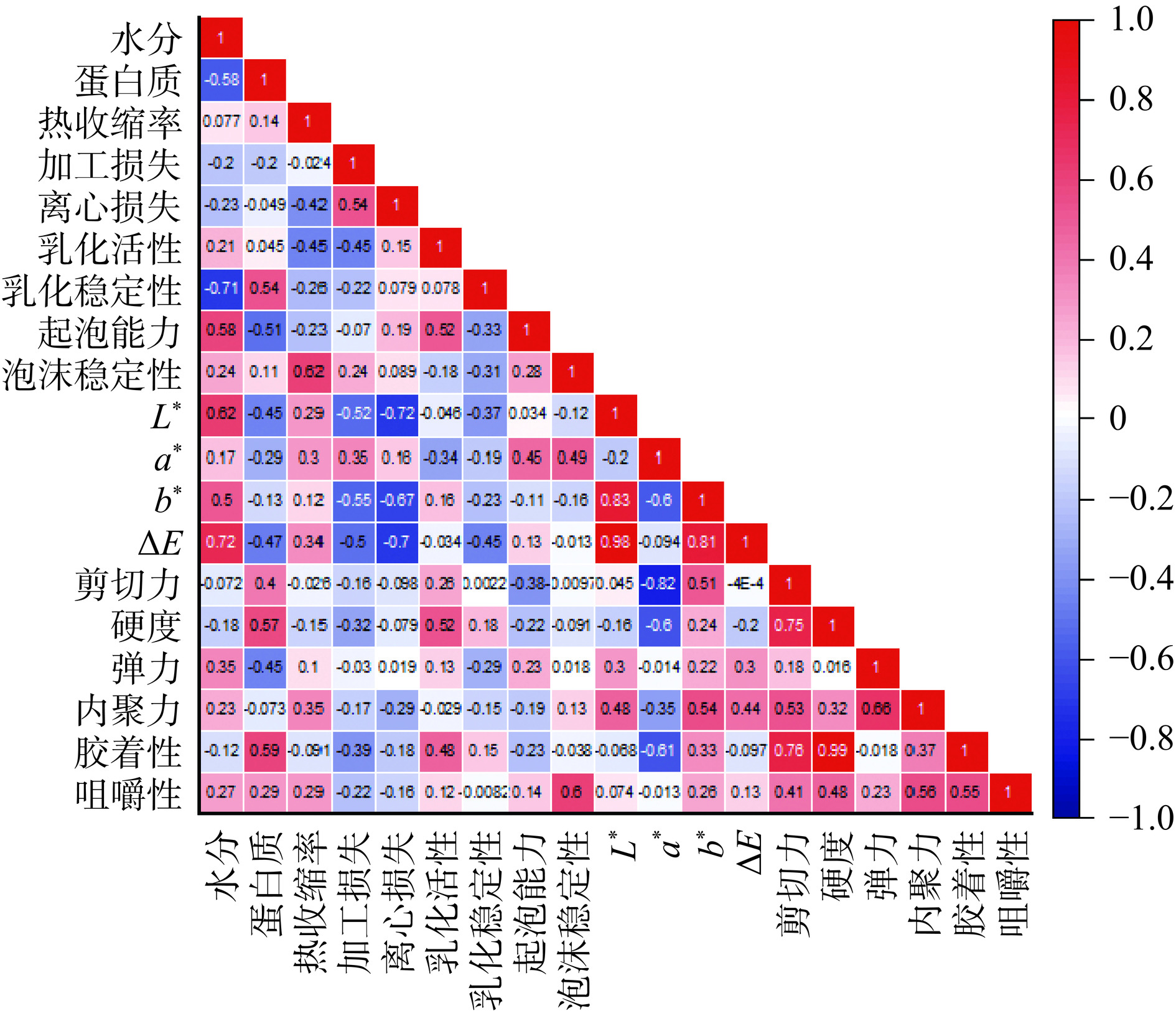

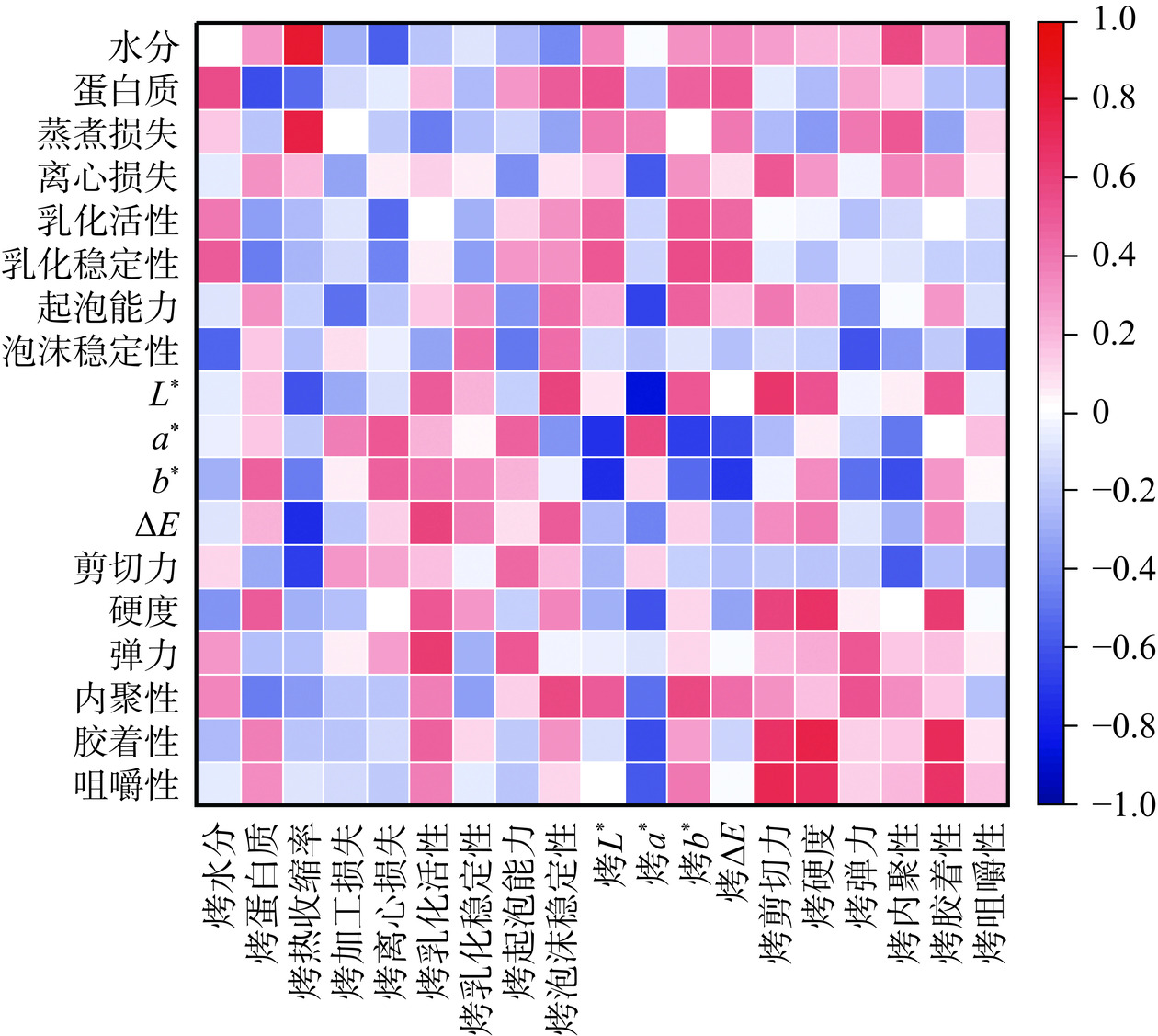

表 8 烤制加工对牦牛胃不同肌层厚度品质指标主成分分析结果Table 8. Principal component analysis results of baking processing on gastric quality indicators of yaks with different muscle layer thicknesses品质指标 PC PC1 PC2 PC3 PC4 PC5 水分 0.496 0.671 0.027 0.403 −0.101 蛋白质 0.025 0.807 0.324 0.229 0.332 热收缩率 −0.226 −0.291 0.717 0.416 0.126 加工损失 0.625 −0.125 0.314 −0.051 −0.560 离心损失 −0.648 −0.174 −0.021 0.513 0.348 乳化活性 −0.268 0.296 −0.395 −0.708 0.264 乳化稳定性 −0.249 −0.610 0.166 −0.251 −0.237 起泡能力 −0.067 0.489 0.113 0.765 −0.320 泡沫稳定性 0.030 −0.233 0.868 −0.232 0.218 L* 0.762 0.530 0.207 −0.272 −0.046 a* −0.555 0.602 −0.371 0.102 −0.296 b* 0.914 0.098 0.198 −0.161 0.018 △E 0.746 0.603 0.138 −0.198 −0.112 剪切力 −0.597 0.612 0.143 −0.096 −0.345 硬度 0.457 −0.782 −0.091 0.282 −0.036 弹力 0.387 0.295 −0.095 0.347 0.535 内聚性 0.722 −0.001 −0.343 0.012 0.439 胶着性 −0.541 0.745 0.134 −0.228 0.098 咀嚼性 −0.486 0.170 0.652 −0.337 0.192 特征值 5.294 4.658 2.508 2.383 1.596 方差贡献率(%) 27.861 24.513 13.198 12.540 8.400 累计贡献率(%) 27.861 52.374 65.572 78.111 86.511 经过烤制加工后牦牛胃不同肌层厚度品质指标相关性分析结果见图13。由图13可看出,水分含量和乳化稳定性、L*、△E值、蛋白质含量、起泡能力、b*值呈显著相关关系(P<0.05);蛋白质含量与乳化稳定性、起泡能力、硬度、胶着性呈显著相关关系(P<0.05);热收缩率和泡沫稳定性呈显著相关关系(P<0.05);离心损失和L*、b*、△E值呈显著相关关系(P<0.05);加工损失与离心损失、L*值、b*值、△E值呈显著相关关系(P<0.05);乳化活性和起泡能力、硬度呈显著相关关系(P<0.05);泡沫稳定性和a*值、咀嚼性呈显著相关关系(P<0.05);L*值和b*、△E值呈显著相关关系(P<0.05);a*值和b*值、硬度、剪切力、胶着性呈显著相关关系(P<0.05);b*值和△E值、剪切力、内聚性呈显著相关关系(P<0.05);剪切力值和硬度、内聚性、胶着性呈显著相关关系(P<0.05);硬度和胶着性呈显著相关关系(P<0.05);弹力和内聚性呈显著相关关系(P<0.05);内聚性和咀嚼性呈显著相关关系(P<0.05);胶着性和咀嚼性呈显著相关关系(P<0.05)。

由以上结果可知,经过烤制加工牦牛胃不同肌层厚度的各项指标之间存在相关性,反映的信息存在不同程度的重叠,为了降低加工适宜性评价负担,需要对以上指标进行筛选,确定关键品质指标。

结合表8、表9及图13结果可知,第一主成分方差贡献为27.861%,代表性指标为L*、b*和△E,其中b*值变异系数较大,且b*与L*和△E均呈现极显著相关关系(P<0.05),因此,选择b*值作为第一主成分代表性指标;第二主成分方差贡献率为24.513%,代表性指标为硬度、蛋白质含量、剪切力和胶着性,剪切力值和硬度、胶着性呈极显著相关(P<0.05),因此,选择剪切力作为第二主成分代表性指标;第三主成分方差贡献率为13.198%,代表性指标为泡沫稳定性、热收缩率、咀嚼性,其中泡沫稳定性与热收缩率呈极显著相关关系(P<0.05),与咀嚼性呈显著相关关系(P<0.05),因此,选择泡沫稳定性作为第三主成分代表指标;第四主成分方差贡献率为12.540%,代表性指标为热收缩率、乳化活性、水分含量和起泡能力,其中起泡能力与乳化活性和水分含量呈显著相关(P<0.05),热收缩率变异系数较小,因此,选择起泡能力作为第四主成分代表指标;第五主成分方差贡献率为8.400%,代表性指标为加工损失、弹力和内聚性,其中弹力变异系数较大,且弹力和内聚性呈极显著相关关系(P<0.05),加工损失变异系数较小,因此,选择弹力作为第五主成分代表指标。指标前5个主成分特征值大于1,累计贡献率达到86.511%,反映了大部分结果的信息,因此,选择前5个主成分进行分析。通过主成分分析和载荷分析,可确定经过烤制牦牛胃不同肌层厚度的评价指标主要为色度因子、质构因子、泡沫因子。

表 9 烤制加工牦牛胃不同肌层厚度品质指标变异系数Table 9. Coefficient of variation for quality indicators of different muscle layer thicknesses in roasted yak stomach品质指标 变异系数(%) 水分 33.52 蛋白质 39.01 热收缩率 23.16 加工损失 8.79 离心损失 45.65 乳化活性 38.99 乳化稳定性 21.25 起泡能力 29.84 泡沫稳定性 30.23 L* 24.36 a* 32.05 b* 44.70 △E 21.19 剪切力 27.17 硬度 71.23 弹力 20.18 内聚性 10.97 胶着性 62.57 咀嚼性 86.22 综上所述,选取b*值、剪切力、泡沫稳定性、起泡能力、弹力为烤制牦牛胃不同肌层厚度的关键品质指标。

2.3.2 烤制加工牦牛胃不同肌层厚度评价指标权重的确定

烤制加工牦牛胃不同肌层厚度关键品质评价指标分别为b*值、剪切力、泡沫稳定性、起泡能力、弹力(表10)。其中b*值和弹力权重最大,泡沫稳定性和起泡能力次之,剪切力最小。

表 10 烤制加工牦牛胃不同肌层厚度的关键品质权重Table 10. Key quality weights of yak stomach with different muscle layer thicknesses during baking processing项目 b*值

(A1)剪切力

(A2)泡沫稳定性

(A3)起泡能力

(A4)弹力

(A5)主成分分析权重 0.14 −0.02 0.05 0.11 0.15 归一化后权重 0.33 −0.05 0.12 0.26 0.35 2.3.3 烤制加工牦牛胃不同肌层厚度综合评价及加工适宜性结果

将关键指标进行正向化和标准化处理,并依据公式Y=0.33A1−0.05A2+0.12A3+0.26A4+0.35A5(A1~A5分别代表b*值、剪切力、泡沫稳定性、起泡能力、弹力),综合品质评价Y值K-means聚类分析结果见表11。

表 11 烤制加工牦牛胃不同肌层厚度综合品质评价得分K-means聚类分析结果Table 11. K-means clustering analysis results of comprehensive quality evaluation scores for yak stomach with different muscle layer thicknesses during baking processing牦牛胃不同肌层厚度(cm) 聚类 距离 烤制加工适宜性 肚领1.5~1.8 1 0.058 适宜 瘤胃1.0~1.2 2 0.054 不适宜 瘤胃0.6~0.9 2 0.046 不适宜 瘤胃0.5 2 0.066 不适宜 瘤胃0.2~0.4 2 0.064 不适宜 网胃1.0~1.2 1 0.033 适宜 网胃0.6~0.9 1 0.028 适宜 网胃0.5 3 0.006 较适宜 网胃0.2~0.4 2 0.056 不适宜 瓣胃1.0~1.2 1 0.053 适宜 瓣胃0.6~0.9 3 0.044 较适宜 瓣胃0.5 3 0.096 较适宜 瓣胃0.2~0.4 2 0.066 不适宜 皱胃1.0~1.2 3 0.054 较适宜 皱胃0.6~0.9 3 0.004 较适宜 皱胃0.5 2 0.014 不适宜 皱胃0.2~0.4 2 0.104 不适宜 根据表11可知,Y为0.65以上为适宜,Y为0.41~0.64为较适宜,Y为0.40以下为不适宜。结果表明,肚领1.5~1.8 cm、网胃1.0~1.2 cm、网胃0.6~0.9 cm、瓣胃1.0~1.2 cm适宜烤制加工,网胃0.5 cm、瓣胃0.6~0.9 cm、瓣胃0.5 cm、皱胃1.0~1.2 cm、皱胃0.6~0.9 cm较适宜烤制加工,瘤胃1.0~1.2 cm、瘤胃0.6~0.9 cm、瘤胃0.5 cm、瘤胃0.2~0.4 cm、网胃0.2~0.4 cm、瓣胃0.2~0.4 cm、皱胃0.5 cm、皱胃0.2~0.4 cm不适宜烤制加工。

2.3.4 烤制加工牦牛胃不同肌层厚度适宜性评价模型的验证

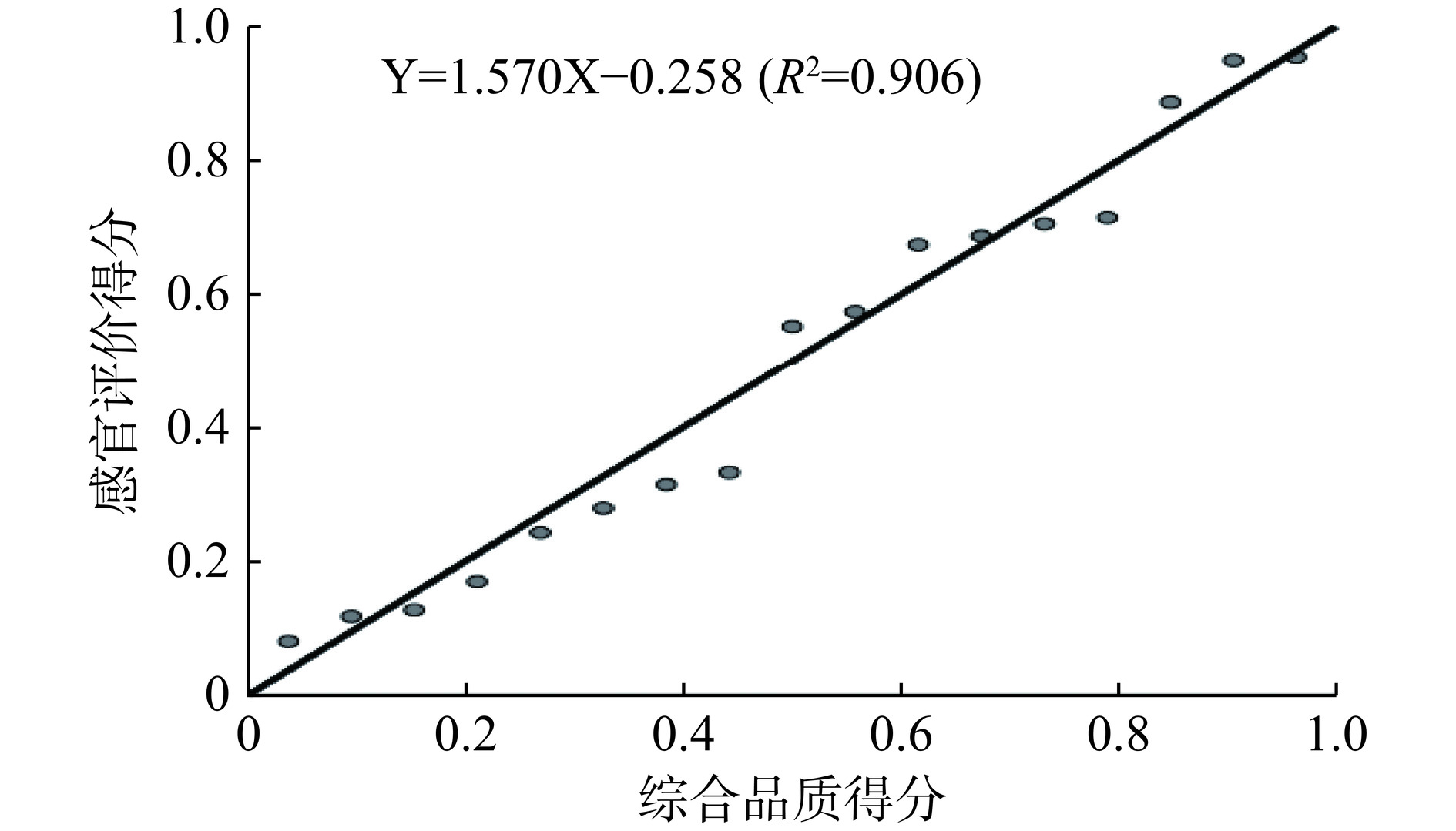

烤制加工牦牛胃不同肌层厚度的感官评价中总体可接受性结果进行标准化处理,以总体可接受性为因变量,综合品质评价为自变量,建立回归方程(图14)。从图14中可以看出,回归方程R2为0.906,表明综合品质评价模型可以较为准确地预测感官总体可接受性,较好地反映烤制牦牛胃不同肌层厚度的加工适宜性。

2.3.5 烤制加工牦牛胃不同肌层厚度对原料肉品质的要求

图15为原料肉品质指标与经过烤制加工后牦牛胃不同肌层厚度品质指标相关性分析结果。从图中可看出,经过烤制加工后的b*值与原料肉的乳化活性与乳化稳定性呈正相关(P<0.05),与b*呈负相关(P<0.05),和内聚性呈正相关(P<0.05),乳化特性是肉制品品质的重要影响因素,乳化性特性高的原料肉所制作出的样品内聚性较好[46];经过烤制加工后的剪切力值和原料肉的弹力呈正相关(P<0.05);经过烤制加工后的泡沫稳定性与原料肉的内聚性、蛋白质含量呈正相关(P<0.05),欧秀琼等[47]认为猪肉中蛋白质含量越多,蛋白质分子形成的空间网络结构越致密,肌肉对外界的抵抗能力越强,因此,瓣胃和皱胃的硬度和弹性越好;经过烤制加工后的起泡能力与原料肉的泡沫稳定性呈负相关(P<0.05),与蛋白质含量呈正相关(P<0.05);经过烤制加工后的弹力和原料肉的弹力、内聚性呈正相关(P<0.05),和b*值呈负相关(P<0.05)。

因此,总体来说,由于每个胃的组织形态不同,瘤胃、网胃、瓣胃和皱胃四个牦牛胃的不同肌层厚度中基本选择乳化活性高、乳化稳定性高、高蛋白质含量,且拥有较好的弹力的部位适合进行烤制加工。这与本试验得出的肚领1.5~1.8 cm、网胃1.0~1.2 cm、网胃0.6~0.9 cm、瓣胃1.0~1.2 cm适宜烤制加工,网胃0.5 cm、瓣胃0.6~0.9 cm、瓣胃0.5 cm、皱胃1.0~1.2 cm、皱胃0.6~0.9 cm较适宜烤制加工,瘤胃1.0~1.2 cm、瘤胃0.6~0.9 cm、瘤胃0.5 cm、瘤胃0.2~0.4 cm、网胃0.2~0.4 cm、瓣胃0.2~0.4 cm、皱胃0.5 cm、皱胃0.2~0.4 cm不适宜烤制加工的结论基本相符。

3. 结论

本文研究了牦牛胃不同肌层厚度的品质特性并利用多元统计分析方法对牦牛胃不同肌层厚度烤制加工适宜性进行评价。结果表明,肚领1.5~1.8 cm、瓣胃1.0~1.2 cm、网胃0.6~1.2 cm适宜烤制加工,网胃0.5 cm、瓣胃0.5~0.9 cm、皱胃0.6~1.2 cm较适宜烤制加工,瘤胃0.2~1.2 cm、皱胃0.2~0.5 cm、网胃和瓣胃0.2~0.4 cm不适宜烤制加工,为牦牛胃的科学加工提供了科学依据。后续应通过研究不同加工方式下牦牛胃的消化特性,进一步揭示不同肌层厚度下烤制牦牛胃的加工适宜性。

-

表 1 烤制感官评分表

Table 1 Roasted sensory scale

项目 适宜(8~10) 较适宜(6~7.9) 不适宜(0~5.9) 外观 外观易于接受 外观可接受度中等 外观不易接受 色泽 表面色泽均匀,有光泽 表面色泽与光泽度中等 表面色泽过深或过浅,无光泽 嫩度 肌丝易咬断,有嚼劲 肌丝不易咬断,嚼劲性小 肌丝难咬断,无嚼劲 多汁性 汁液丰富,易下咽 多汁感较好 口感粗糙,难下咽 风味 肉香浓郁 肉香柔和 轻微肉香或香气不协调 整体可接受性 完全可以接受 比较可以接受 不能接受 表 2 牦牛胃不同肌层厚度乳化活性和乳化稳定性变化

Table 2 Changes in emulsification activity and emulsification stability in yak stomach with different muscular layer thicknesses

乳化活性(EA) 乳化稳定性(ES) 肚领1.5~1.8 cm 0.18±0.02d 13.31±0.30de 瘤胃1.0~1.2 cm 0.21±0.00c 12.73±0.47e 瘤胃0.6~0.9 cm 0.18±0.00de 15.99±1.01c 瘤胃0.5 cm 0.15±0.00f 6.47±0.07hi 瘤胃0.2~0.4 cm 0.13±0.01g 6.53±0.09ghi 网胃1.0~1.2 cm 0.65±0.02a 20.81±0.83b 网胃0.6~0.9 cm 0.58±0.00b 22.14±0.35a 网胃0.5 cm 0.10±0.00h 7.70±0.35g 网胃0.2~0.4 cm 0.05±0.00jk 9.64±0.01f 瓣胃1.0~1.2 cm 0.17±0.02def 14.29±1.58d 瓣胃0.6~0.9 cm 0.16±0.00ef 9.91±0.45f 瓣胃0.5 cm 0.10±0.00h 9.10±0.16f 瓣胃0.2~0.4 cm 0.06±0.00j 7.47±0.18gh 皱胃1.0~1.2 cm 0.08±0.00i 9.15±0.04f 皱胃0.6~0.9 cm 0.06±0.01j 5.71±0.26ij 皱胃0.5 cm 0.04±0.00kl 5.19±0.33j 皱胃0.2~0.4 cm 0.03±0.00l 5.57±0.65ij 注:表中小写字母表示不同肌层厚度差异显著(P<0.05),表3~表7同。 表 3 牦牛不同肌层厚度胃肉色值变化

Table 3 Changes in gastric meat color values of yaks with different muscle layer thicknesses

样品 L* a* b* △E 肚领1.5~1.8 cm 70.46±0.41abc 10.47±0.10gh 9.67±0.31e 71.89±0.38abc 瘤胃1.0~1.2 cm 71.24±1.74ab 14.80±0.56cdef 12.87±1.28cd 73.90±1.42ab 瘤胃0.6~0.9 cm 72.20±0.21a 14.42±0.15def 10.82±0.76de 74.42±0.20ab 瘤胃0.5 cm 72.21±0.76a 17.49±0.69c 16.77±2.18a 76.19±0.94a 瘤胃0.2~0.4 cm 72.92±1.36a 16.30±2.80cd 14.50±2.23abc 76.17±1.61a 网胃1.0~1.2 cm 67.29±1.25d 14.36±0.52def 8.47±0.12e 69.32±1.30de 网胃0.6~0.9 cm 68.76±0.43bcd 15.31±1.18cde 5.91±2.08f 70.55±0.69bcd 网胃0.5 cm 66.87±1.39d 13.00±2.17efg 3.80±1.15fg 67.99±1.73e 网胃0.2~0.4 cm 67.54±1.58cd 12.28±1.28fg 3.57±0.83fg 68.50±2.06e 瓣胃1.0~1.2 cm 63.29±1.61e 7.56±1.40i 1.68±0.77g 63.23±1.79f 瓣胃0.6~0.9 cm 61.95±1.61ef 7.09±1.74i 1.35±0.20g 62.71±1.76f 瓣胃0.5 cm 59.26±1.67fgh 6.08±1.03i 1.65±0.31g 59.61±1.59g 瓣胃0.2~0.4 cm 61.06±1.15efg 8.31±1.77hi 1.34±1.06g 61.66±1.01fg 皱胃1.0~1.2 cm 58.85±2.42gh 32.66±2.02a 15.23±2.09abc 69.04±2.70de 皱胃0.6~0.9 cm 59.53±0.97fgh 31.83±1.03b 15.05±0.54abc 69.11±1.66de 皱胃0.5 cm 58.07±1.38h 29.48±0.69ab 15.91±0.09ab 67.80±0.57e 皱胃0.2~0.4 cm 58.43±1.34gh 17.59±1.03c 13.55±0.99bc 62.85±1.52f 表 4 牦牛不同肌层厚度胃剪切力和质构变化

Table 4 Changes in gastric shear force and texture of yaks with different muscle layer thicknesses

剪切力(kg) 硬度(kg) 弹力 内聚性 胶着性(kg) 咀嚼性(mJ) 肚领1.5~1.8 cm 9.74±0.40d 3.10±0.08ef 0.50±0.03cd 0.78±0.02bcd 2.24±0.16fg 1859.55±254.19d 瘤胃1.0~1.2 cm 14.22±0.39a 1.84±0.24h 0.33±0.01ef 0.74±0.03cde 1.34±0.12hi 1181.79±151.11ef 瘤胃0.6~0.9 cm 13.27±1.16ab 5.70±0.46b 0.46±0.02d 0.78±0.08bcde 3.12±0.58de 1285.92±36.81e 瘤胃0.5 cm 10.39±0.50d 5.10±1.09bc 0.50±0.04cd 0.77±0.07bcde 3.91±0.90bc 2581.33±108.15c 瘤胃0.2~0.4 cm 9.70±0.33d 8.43±0.44a 0.52±0.03bcd 0.87±0.07ab 6.47±0.69a 5205.83±14.65a 网胃1.0~1.2 cm 13.41±0.97ab 2.14±0.19gh 0.36±0.01e 0.86±0.00abc 2.45±0.38ef 2499.44±235.59c 网胃0.6~0.9 cm 13.23±0.87ab 3.76±0.46de 0.52±0.03bcd 0.85±0.14abc 3.52±0.36cd 2869.78±99.45c 网胃0.5 cm 11.56±0.09c 3.99±0.55de 0.57±0.03bc 0.85±0.03abc 3.36±0.39cd 4046.57±61.78b 网胃0.2~0.4 cm 8.10±0.29e 4.50±0.38cd 0.58±0.05b 0.82±0.07abcd 4.16±0.19b 4452.53±762.23b 瓣胃1.0~1.2 cm 9.52±0.26d 2.14±0.24gh 0.46±0.02d 0.93±0.01a 1.67±0.26fghi 742.13±40.04ghi 瓣胃0.6~0.9 cm 8.42±0.15e 1.82±0.14h 0.38±0.03e 0.71±0.06de 1.62±0.29ghi 530.58±5.84hi 瓣胃0.5 cm 8.28±0.25e 1.64±0.13h 0.33±0.02ef 0.76±0.07bcde 1.38±0.08hi 288.33±48.91i 瓣胃0.2~0.4 cm 7.36±0.27e 1.82±0.21h 0.34±0.02ef 0.66±0.06ef 1.44±0.09hi 437.85±39.99hi 皱胃1.0~1.2 cm 13.10±0.18b 2.85±0.48fg 0.81±0.02a 0.75±0.06bcde 2.05±0.26fg 1097.91±38.02efg 皱胃0.6~0.9 cm 12.58±0.34bc 2.42±0.03fgh 0.37±0.05e 0.57±0.03f 1.85±0.19fgh 762.30±23.14fgh 皱胃0.5 cm 9.57±0.12d 2.15±0.20gh 0.27±0.03fg 0.35±0.05g 1.32±0.26hi 730.00±105.43ghi 皱胃0.2~0.4 cm 9.51±0.26d 1.82±0.66h 0.25±0.05g 0.25±0.03g 1.06±0.04i 753.89±39.38fgh 表 5 烤制加工对不同肌层厚度牦牛肉色的影响

Table 5 Effect of baking processing on the color of yak meat with different muscle layer thicknesses

L* a* b* △E 肚领1.5~1.8 cm 58.72±1.05a 9.11±0.30h 28.05±1.72a 65.72±1.41a 瘤胃1.0~1.2 cm 34.19±0.58hi 12.15±0.76g 10.48±1.06gh 37.78±0.37i 瘤胃0.6~0.9 cm 32.99±0.64ij 11.85±0.91g 11.27±1.01fg 36.84±0.85i 瘤胃0.5 cm 32.93±0.65ij 8.93±0.66h 15.11±0.73de 37.32±0.44i 瘤胃0.2~0.4 cm 35.39±0.03h 7.99±0.83h 13.68±2.07e 39.01±0.60hi 网胃1.0~1.2 cm 54.77±3.02b 15.80±1.05de 19.79±1.46c 60.35±3.25c 网胃0.6~0.9 cm 48.72±0.51d 15.50±0.81def 22.48±1.07b 55.86±0.74de 网胃0.5 cm 46.54±0.77e 13.96±0.37f 19.66±1.13c 52.42±0.78f 网胃0.2~0.4 cm 41.80±0.25g 11.44±0.52g 17.02±0.83d 46.56±0.37g 瓣胃1.0~1.2 cm 57.64±0.40a 19.42±1.08c 16.87±0.35d 63.13±0.09b 瓣胃0.6~0.9 cm 54.40±1.20c 16.17±0.28d 16.74±0.32d 58.42±1.15d 瓣胃0.5 cm 49.33±0.59cd 16.01±0.71de 14.89±1.14de 53.97±0.67ef 瓣胃0.2~0.4 cm 44.10±0.62f 14.23±1.15ef 13.48±0.73ef 48.27±0.99g 皱胃1.0~1.2 cm 29.26±0.49k 24.21±1.34a 3.84±0.60j 38.19±0.93hi 皱胃0.6~0.9 cm 31.43±1.28j 22.14±1.07b 4.52±1.01j 38.74±0.65hi 皱胃0.5 cm 31.27±0.16jk 22.16±1.15b 6.90±0.43i 38.96±0.62hi 皱胃0.2~0.4 cm 33.76±0.86hi 20.29±0.83c 8.47±1.19hi 40.30±1.05h 表 6 烤制加工对不同肌层厚度牦牛剪切力和质构的影响

Table 6 Effect of baking processing on shear force and texture of yaks with different muscle layer thicknesses

剪切力(kg) 硬度(kg) 弹力 内聚性 胶着性(kg) 咀嚼性(mJ) 肚领1.5~1.8 cm 10.63±0.23b 4.07±0.63c 0.33±0.03cde 0.81±0.04abc 3.24±0.75c 2337.73±482.90ab 瘤胃1.0~1.2 cm 7.43±0.20ef 1.76±0.03ghi 0.27±0.03fg 0.64±0.03g 1.07±0.01hij 60.00±5.16f 瘤胃0.6~0.9 cm 7.75±0.18e 1.33±0.15ij 0.29±0.02def 0.68±0.07efg 1.20±0.06ghij 62.27±10.68f 瘤胃0.5 cm 10.46±0.17b 7.43±0.33a 0.33±0.03cde 0.82±0.00ab 4.87±0.55a 1639.67±152.05cd 瘤胃0.2~0.4 cm 10.26±0.09bc 6.58±0.31b 0.28±0.02ef 0.69±0.03defg 4.28±0.43ab 253.53±31.00f 网胃1.0~1.2 cm 6.89±0.19g 2.47±0.23ef 0.40±0.03ab 0.67±0.02efg 1.72±0.03efg 124.50±12.46f 网胃0.6~0.9 cm 8.49±0.43d 2.84±0.11de 0.41±0.01a 0.78±0.05bcd 2.20±0.14de 1950.40±136.94bc 网胃0.5 cm 10.06±0.02c 2.12±0.12fgh 0.34±0.02cd 0.83±0.01ab 2.14±0.27de 1244.67±128.85de 网胃0.2~0.4 cm 11.50±0.17a 6.08±0.39b 0.22±0.06gh 0.88±0.00a 4.17±0.09b 2609.80±134.46a 瓣胃1.0~1.2 cm 4.30±0.15j 0.72±0.025k 0.42±0.01a 0.74±0.01cde 0.60±0.03j 131.03±23.10f 瓣胃0.6~0.9 cm 6.35±0.10h 2.25±0.37efg 0.35±0.01bc 0.86±0.02a 1.84±0.18ef 1704.10±229.67c 瓣胃0.5 cm 7.27±0.08f 1.52±0.40hij 0.34±0.04cd 0.82±0.02abc 1.51±0.23fgh 899.87±28.79e 瓣胃0.2~0.4 cm 8.32±0.14d 1.04±0.13jk 0.34±0.00cd 0.82±0.02abc 0.80±0.15ij 43.63±1.23f 皱胃1.0~1.2 cm 4.47±0.16j 1.06±0.15jk 0.35±0.04bc 0.66±0.02fg 0.60±0.09j 405.93±20.12f 皱胃0.6~0.9 cm 7.30±0.15f 2.64±0.30def 0.38±0.00abc 0.72±0.06def 1.75±0.35efg 1614.77±316.88cd 皱胃0.5 cm 6.32±0.19hi 3.24±0.29d 0.25±0.04fg 0.72±0.07def 2.65±0.14cd 2537.70±456.44a 皱胃0.2~0.4 cm 5.96±0.03i 1.44±0.28ij 0.19±0.01h 0.62±0.07g 1.21±0.32ghi 834.00±97.96e 表 7 烤制加工对牦牛胃不同肌层厚度感官评价的影响

Table 7 Effect of baking processing on sensory evaluation of yak stomach with different muscle layer thicknesses

外观 色泽 嫩度 多汁性 风味 整体可接受性 肚领1.5~1.8 cm 8.20±1.96abcd 8.37±1.74abc 8.43±0.87abc 8.63±0.82a 9.09±1.08a 9.37±0.10a 瘤胃1.0~1.2 cm 8.03±0.89abcd 8.20±0.98bc 5.38±0.71de 5.04±1.02c 5.52±1.74e 6.15±1.36defg 瘤胃0.6~0.9 cm 8.28±1.91abc 8.17±1.78bc 5.40±0.73de 5.39±1.69c 5.60±1.09e 6.25±1.15defg 瘤胃0.5 cm 8.11±1.19abcd 8.04±1.56bc 5.53±0.76de 5.32±1.79c 5.42±1.21e 6.14±1.62defg 瘤胃0.2~0.4 cm 7.34±1.06de 7.87±1.80bc 5.57±1.64d 5.38±1.00c 5.61±0.80e 6.07±1.45efg 网胃1.0~1.2 cm 8.14±0.90abcd 8.26±0.94bc 8.76±1.56a 8.53±1.51a 8.33±0.58abc 8.98±0.71ab 网胃0.6~0.9 cm 8.39±1.27ab 8.35±0.86abc 8.08±1.63abc 7.92±1.02ab 8.78±0.67ab 8.65±0.58abc 网胃0.5 cm 8.07±1.96abcd 8.00±1.13bc 7.87±1.76bc 5.72±0.53c 7.76±1.66cd 7.25±0.38cdef 网胃0.2~0.4 cm 7.28±1.48de 8.07±1.06bc 4.98±1.71de 5.25±1.66c 5.49±0.63e 5.73±1.29fg 瓣胃1.0~1.2 cm 8.10±0.72abcd 9.04±0.36a 8.74±1.58ab 8.49±0.95a 7.56±1.12cd 8.39±0.35abc 瓣胃0.6~0.9 cm 8.21±1.71abcd 8.36±1.47abc 7.66±0.48c 7.53±1.04b 7.66±1.47cd 8.06±1.18abc 瓣胃0.5 cm 7.06±1.63e 7.99±1.62bc 5.53±1.01de 4.99±1.09c 5.55±1.04e 6.15±0.55defg 瓣胃0.2~0.4 cm 7.00±0.79e 7.61±1.23c 5.59±0.69d 7.71±0.64ab 5.92±1.38e 5.84±1.05fg 皱胃1.0~1.2 cm 8.66±1.56a 9.06±0.75a 8.02±0.79abc 7.95±1.73ab 7.84±1.09bcd 7.59±1.13bcdef 皱胃0.6~0.9 cm 8.07±1.46abcd 8.25±0.68bc 7.96±1.46abc 7.86±1.77ab 7.09±1.20d 7.74±1.61abcd 皱胃0.5 cm 7.68±1.49bcde 8.20±1.71bc 4.66±1.02e 5.58±1.65c 5.27±0.69e 5.92±1.04fg 皱胃0.2~0.4 cm 7.35±1.59cde 8.61±1.17ab 5.05±0.59de 4.84±1.79c 5.42±1.53e 4.66±0.61g 表 8 烤制加工对牦牛胃不同肌层厚度品质指标主成分分析结果

Table 8 Principal component analysis results of baking processing on gastric quality indicators of yaks with different muscle layer thicknesses

品质指标 PC PC1 PC2 PC3 PC4 PC5 水分 0.496 0.671 0.027 0.403 −0.101 蛋白质 0.025 0.807 0.324 0.229 0.332 热收缩率 −0.226 −0.291 0.717 0.416 0.126 加工损失 0.625 −0.125 0.314 −0.051 −0.560 离心损失 −0.648 −0.174 −0.021 0.513 0.348 乳化活性 −0.268 0.296 −0.395 −0.708 0.264 乳化稳定性 −0.249 −0.610 0.166 −0.251 −0.237 起泡能力 −0.067 0.489 0.113 0.765 −0.320 泡沫稳定性 0.030 −0.233 0.868 −0.232 0.218 L* 0.762 0.530 0.207 −0.272 −0.046 a* −0.555 0.602 −0.371 0.102 −0.296 b* 0.914 0.098 0.198 −0.161 0.018 △E 0.746 0.603 0.138 −0.198 −0.112 剪切力 −0.597 0.612 0.143 −0.096 −0.345 硬度 0.457 −0.782 −0.091 0.282 −0.036 弹力 0.387 0.295 −0.095 0.347 0.535 内聚性 0.722 −0.001 −0.343 0.012 0.439 胶着性 −0.541 0.745 0.134 −0.228 0.098 咀嚼性 −0.486 0.170 0.652 −0.337 0.192 特征值 5.294 4.658 2.508 2.383 1.596 方差贡献率(%) 27.861 24.513 13.198 12.540 8.400 累计贡献率(%) 27.861 52.374 65.572 78.111 86.511 表 9 烤制加工牦牛胃不同肌层厚度品质指标变异系数

Table 9 Coefficient of variation for quality indicators of different muscle layer thicknesses in roasted yak stomach

品质指标 变异系数(%) 水分 33.52 蛋白质 39.01 热收缩率 23.16 加工损失 8.79 离心损失 45.65 乳化活性 38.99 乳化稳定性 21.25 起泡能力 29.84 泡沫稳定性 30.23 L* 24.36 a* 32.05 b* 44.70 △E 21.19 剪切力 27.17 硬度 71.23 弹力 20.18 内聚性 10.97 胶着性 62.57 咀嚼性 86.22 表 10 烤制加工牦牛胃不同肌层厚度的关键品质权重

Table 10 Key quality weights of yak stomach with different muscle layer thicknesses during baking processing

项目 b*值

(A1)剪切力

(A2)泡沫稳定性

(A3)起泡能力

(A4)弹力

(A5)主成分分析权重 0.14 −0.02 0.05 0.11 0.15 归一化后权重 0.33 −0.05 0.12 0.26 0.35 表 11 烤制加工牦牛胃不同肌层厚度综合品质评价得分K-means聚类分析结果

Table 11 K-means clustering analysis results of comprehensive quality evaluation scores for yak stomach with different muscle layer thicknesses during baking processing

牦牛胃不同肌层厚度(cm) 聚类 距离 烤制加工适宜性 肚领1.5~1.8 1 0.058 适宜 瘤胃1.0~1.2 2 0.054 不适宜 瘤胃0.6~0.9 2 0.046 不适宜 瘤胃0.5 2 0.066 不适宜 瘤胃0.2~0.4 2 0.064 不适宜 网胃1.0~1.2 1 0.033 适宜 网胃0.6~0.9 1 0.028 适宜 网胃0.5 3 0.006 较适宜 网胃0.2~0.4 2 0.056 不适宜 瓣胃1.0~1.2 1 0.053 适宜 瓣胃0.6~0.9 3 0.044 较适宜 瓣胃0.5 3 0.096 较适宜 瓣胃0.2~0.4 2 0.066 不适宜 皱胃1.0~1.2 3 0.054 较适宜 皱胃0.6~0.9 3 0.004 较适宜 皱胃0.5 2 0.014 不适宜 皱胃0.2~0.4 2 0.104 不适宜 -

[1] 刘敏, 李升升, 张强龙, 等. 牛胃加工利用研究进展[J/OL]. 甘肃农业大学学报:1−14[2025-01-23]. http://kns.cnki.net/kcms/detail/62.1055.S.20230901.1330.002.html. [LIU Min, LI Shengsheng, ZHANG Qianglong, et al. Research progress on the processing and utilization of bovine stomach[J/OL]. Journal of Gansu Agricultural University:1−14[2025-01-23]. http://kns.cnki.net/kcms/detail/62.1055.S.20230901.1330.002.html.] LIU Min, LI Shengsheng, ZHANG Qianglong, et al. Research progress on the processing and utilization of bovine stomach[J/OL]. Journal of Gansu Agricultural University: 1−14[2025-01-23]. http://kns.cnki.net/kcms/detail/62.1055.S.20230901.1330.002.html.

[2] 曹兵海, 李俊雅, 王之盛, 等. 2022年度肉牛牦牛产业技术发展报告[J]. 中国畜牧杂志,2023,59(3):330−335. [CAO Binghai, LI Junya, WANG Zhisheng, et al. 2022 Technical development report on beef and yak industry[J]. Chinese Journal of Animal Husbandry,2023,59(3):330−335.] CAO Binghai, LI Junya, WANG Zhisheng, et al. 2022 Technical development report on beef and yak industry[J]. Chinese Journal of Animal Husbandry, 2023, 59(3): 330−335.

[3] 曹兵海, 张越杰, 李俊雅, 等. 2020年度肉牛牦牛产业技术发展报告[J]. 中国畜牧杂志,2021,57(3):240−245. [CAO Binghai, ZHANG Yuejie, LI Junya, et al. 2020 Technical development report on beef and yak industry[J]. Chinese Journal of Animal Husbandry,2021,57(3):240−245.] CAO Binghai, ZHANG Yuejie, LI Junya, et al. 2020 Technical development report on beef and yak industry[J]. Chinese Journal of Animal Husbandry, 2021, 57(3): 240−245.

[4] 王丽媛, 高艳蕾, 张丽, 等. 畜禽副产物的加工利用现状及研究展望[J]. 食品科技,2022,47(6):174−183. [WANG Liyuan, GAO Yanlei, ZHANG Li, et al. The current status and research prospects of processing and utilization of livestock and poultry by-products[J]. Food Technology,2022,47(6):174−183.] WANG Liyuan, GAO Yanlei, ZHANG Li, et al. The current status and research prospects of processing and utilization of livestock and poultry by-products[J]. Food Technology, 2022, 47(6): 174−183.

[5] 王莉, 郭丽君, 张秀英, 等. 基于模糊数学感官评价法优化烧烤牛肚的制作工艺[J]. 食品工业科技,2018,39(19):200−205. [WANG Li, GUO Lijun, ZHANG Xiuying, et al. Optimization of the production process of grilled beef tripe based on fuzzy mathematical sensory evaluation method[J]. Technology of Food Industry,2018,39(19):200−205.] WANG Li, GUO Lijun, ZHANG Xiuying, et al. Optimization of the production process of grilled beef tripe based on fuzzy mathematical sensory evaluation method[J]. Technology of Food Industry, 2018, 39(19): 200−205.

[6] LIU H, MA J R, PAN T, et al. Effects of roasting by charcoal, electric, microwave and superheated steam methods on (non)volatile compounds in oyster cuts of roasted lamb[J]. Meat Science,2021,172:108324. doi: 10.1016/j.meatsci.2020.108324

[7] THOMPSON J M, HOPKINS D L, D’SOUZA D N, et al. The impact of processing on sensory and objective measurements of sheep meat eating quality[J]. Australian Journal of Experimental Agriculture,2005,45(5):561. doi: 10.1071/EA03195

[8] 孙晓明, 张佳程, 卢凌, 等. 牛胴体部位肉营养成分和理化指标差异性分析[J]. 中国畜牧兽医,2011,38(2):205−208. [SUN Xiaoming, ZHANG Jiacheng, LU Ling, et al. Analysis of differences in nutritional composition and physicochemical indicators of beef carcass parts[J]. Chinese Animal Husbandry and Veterinary Medicine,2011,38(2):205−208.] SUN Xiaoming, ZHANG Jiacheng, LU Ling, et al. Analysis of differences in nutritional composition and physicochemical indicators of beef carcass parts[J]. Chinese Animal Husbandry and Veterinary Medicine, 2011, 38(2): 205−208.

[9] 宋洁. 巴寒杂交羔羊不同部位肉加工适宜性研究[D]. 兰州:甘肃农业大学, 2016. [SONG Jie. Study on the suitability of meat processing in different parts of Ba Han hybrid lambs[D]. Lanzhou:Gansu Agricultural University, 2016.] SONG Jie. Study on the suitability of meat processing in different parts of Ba Han hybrid lambs[D]. Lanzhou: Gansu Agricultural University, 2016.

[10] 罗天林. 宰后牛胃肠冷藏过程中品质变化规律及其加工适宜性研究[D]. 兰州:甘肃农业大学, 2017. [LUO Tianlin. Study on the quality changes and processing suitability of postmortem cattle during gastrointestinal refrigeration[D]. Lanzhou:Gansu Agricultural University, 2017.] LUO Tianlin. Study on the quality changes and processing suitability of postmortem cattle during gastrointestinal refrigeration[D]. Lanzhou: Gansu Agricultural University, 2017.

[11] 郝婉名. 西门塔尔杂交牛不同部位肉的品质特性与加工传统牛肉产品适宜性研究[D]. 郑州:河南农业大学, 2020. [HAO Wanming. A study on the quality characteristics of meat from different parts of Simmental hybrid cattle and the suitability for processing traditional beef products[D]. Zhengzhou:Henan Agricultural University, 2020.] HAO Wanming. A study on the quality characteristics of meat from different parts of Simmental hybrid cattle and the suitability for processing traditional beef products[D]. Zhengzhou: Henan Agricultural University, 2020.

[12] 王妍. 牦牛瘤胃蛋白质功能特性研究及其三种烹饪方式加工工艺优化[D]. 兰州:甘肃农业大学, 2018. [WANG Yan. Research on the functional characteristics of yak rumen protein and optimization of three cooking methods and processing techniques[D]. Lanzhou:Gansu Agricultural University, 2018.] WANG Yan. Research on the functional characteristics of yak rumen protein and optimization of three cooking methods and processing techniques[D]. Lanzhou: Gansu Agricultural University, 2018.

[13] 国家卫生和计划生育委员会, GB 5009.5-2016, 食品安全国家标准 食品中蛋白质的测定[S]. 北京:中国科学出版社, 2016. [National Health and Family Planning Commission, GB 5009.5-2016, National Standard for Food Safety Determination of protein in foods[S]. Beijing: Science Press of China, 2016.] National Health and Family Planning Commission, GB 5009.5-2016, National Standard for Food Safety Determination of protein in foods[S]. Beijing: Science Press of China, 2016.

[14] 国家卫生和计划生育委员会, GB 5009.3-2016, 食品安全国家标准 食品中水分的测定[S]. 北京:中国科学出版社, 2016. [National Health and Family Planning Commission, GB 5009.3-2016, National Standard for Food Safety Determination of moisture in food[S]. Beijing: Science Press of China, 2016.] National Health and Family Planning Commission, GB 5009.3-2016, National Standard for Food Safety Determination of moisture in food[S]. Beijing: Science Press of China, 2016.

[15] 李升升. 基于蛋白质组学的牦牛平滑肌嫩度形成机制研究[D]. 兰州:甘肃农业大学, 2019. [LI Shengsheng. Research on the mechanism of yak smooth muscle tenderness formation based on proteomics[D]. Lanzhou:Gansu Agricultural University, 2019.] LI Shengsheng. Research on the mechanism of yak smooth muscle tenderness formation based on proteomics[D]. Lanzhou: Gansu Agricultural University, 2019.

[16] 陈玉茹. 酸碱处理对毛肚食用品质的影响研究[D]. 南京:南京农业大学, 2020. [CHEN Yuru. A study on the effect of acid-base treatment on the edible quality of hairy tripe[D]. Nanjing:Nanjing Agricultural University, 2020.] CHEN Yuru. A study on the effect of acid-base treatment on the edible quality of hairy tripe[D]. Nanjing: Nanjing Agricultural University, 2020.

[17] 王妍, 马纪兵, 崔文斌, 等. 热加工对牦牛瘤胃主要蛋白含量及其功能特性的影响[J]. 食品与发酵工业,2019,45(4):174−180. [WANG Yan, MA Jibing, CUI Wenbin, et al. The effect of thermal processing on the main protein content and functional characteristics of yak rumen[J]. Food and Fermentation Industry,2019,45(4):174−180.] WANG Yan, MA Jibing, CUI Wenbin, et al. The effect of thermal processing on the main protein content and functional characteristics of yak rumen[J]. Food and Fermentation Industry, 2019, 45(4): 174−180.

[18] PEARCE K N, KINSELLA J E. Emulsifying properties of proteins:evaluation of a turbidimetric technique[J]. Journal of Agricultural and Food Chemistry,1978,26(3):716−723. doi: 10.1021/jf60217a041

[19] PLANCKEN D V I, LOEY V A, HENDRICKX E M. Foaming properties of egg white proteins affected by heat or high pressure treatment[J]. Journal of Food Engineering,2007,78(4):1410−1426. doi: 10.1016/j.jfoodeng.2006.01.013

[20] 张萌, 李亚蕾. 宰后贮藏期间氧化磷酸化对秦川牛肉色泽的影响[J]. 中国食品学报,2023,23(10):249−260. [ZHANG Meng, LI Yalei. Effects of oxidative phosphorylation on the color of Qinchuan beef during post-slaughter storage[J]. Chinese Journal of Food Science,2023,23(10):249−260.] ZHANG Meng, LI Yalei. Effects of oxidative phosphorylation on the color of Qinchuan beef during post-slaughter storage[J]. Chinese Journal of Food Science, 2023, 23(10): 249−260.

[21] 李升升, 余群力, 靳义超. 适宜加热温度保持牦牛瘤胃平滑肌加工品质和组织结构[J]. 农业工程学报,2017,33(23):300−305. [LI Shengsheng, YU Qunli, JIN Yichao. Suitable heating temperature to maintain the processing quality and tissue structure of yak rumen smooth muscle[J]. Journal of Agricultural Engineering,2017,33(23):300−305.] LI Shengsheng, YU Qunli, JIN Yichao. Suitable heating temperature to maintain the processing quality and tissue structure of yak rumen smooth muscle[J]. Journal of Agricultural Engineering, 2017, 33(23): 300−305.

[22] 张燕, 李升升, 赵立柱. 基于主成分和聚类分析的藏羊部位肉品质评价[J]. 食品科技,2022,47(4):128−133. [ZHANG Yan, LI Shengsheng, ZHAO Lizhu. Evaluation of meat quality of tibetan sheep parts based on principal component analysis and cluster analysis[J]. Food Technology,2022,47(4):128−133.] ZHANG Yan, LI Shengsheng, ZHAO Lizhu. Evaluation of meat quality of tibetan sheep parts based on principal component analysis and cluster analysis[J]. Food Technology, 2022, 47(4): 128−133.

[23] 国家质量监督检验检疫总局, GB/T 22210-2008, 肉与肉制品感官评定规范[S]. 北京:中国科学出版社, 2008. [PRC State Administration of Quality Supervision and Quarantine, GB/T 22210-2008, Code of practice for the sensory evaluation of meat and meat products[S]. Beijing: Science Press of China, 2008.] PRC State Administration of Quality Supervision and Quarantine, GB/T 22210-2008, Code of practice for the sensory evaluation of meat and meat products[S]. Beijing: Science Press of China, 2008.

[24] 张文霖. 主成分分析在满意度权重确定中的应用[J]. 市场研究,2006(6):18−22. [ZHANG Wenlin. The application of principal component analysis in determining satisfaction weights[J]. Market Research,2006(6):18−22.] ZHANG Wenlin. The application of principal component analysis in determining satisfaction weights[J]. Market Research, 2006(6): 18−22.

[25] 刘敏, 李升升, 张艳, 等. 不同肌层厚度牦牛瘤胃的品质研究[J/OL]. 甘肃农业大学学报, 2024[2024-06-17]. http://kns.cnki.net/kcms/detail/62.1055.s.20240511.1621.018.html. [LIU Min, LI Shengsheng, ZHANG Yan, et al. Study on the quality of yak rumen with different muscle layer thickness[J/OL]. Journal of Gansu Agricultural University:1−16[2024-06-17]. http://kns.cnki.net/kcms/detail/62.1055.s.20240511.1621.018.html.] LIU Min, LI Shengsheng, ZHANG Yan, et al. Study on the quality of yak rumen with different muscle layer thickness[J/OL]. Journal of Gansu Agricultural University: 1−16[2024-06-17]. http://kns.cnki.net/kcms/detail/62.1055.s.20240511.1621.018.html.

[26] 王珏. 不同品种及不同贮藏方式冷鲜鸡肉品质比较研究[D]. 扬州:扬州大学, 2020. [WANG Jue. Comparative study on the quality of cold fresh chicken with different varieties and storage methods[D]. Yangzhou:Yangzhou University, 2020.] WANG Jue. Comparative study on the quality of cold fresh chicken with different varieties and storage methods[D]. Yangzhou: Yangzhou University, 2020.

[27] 赵改名, 王可, 祝超智, 等. 青海高原型牦牛不同部位肉的品质差异研究[J]. 食品研究与开发,2020,41(13):60−65. [ZHAO Gaiming, WANG Ke, ZHU Chaozhi, et al. A study on the quality differences of meat from different parts of qinghai plateau yak[J]. Food Research and Development,2020,41(13):60−65.] ZHAO Gaiming, WANG Ke, ZHU Chaozhi, et al. A study on the quality differences of meat from different parts of qinghai plateau yak[J]. Food Research and Development, 2020, 41(13): 60−65.

[28] 胡铁军, 闫革华, 邹尔新, 等. 全牛肉乳化香肠的研制[J]. 肉类工业,2000(11):29−33. [HU Tiejun, YAN Gehua, ZOU Erxin, et al. Development of whole beef emulsified sausage[J]. Meat Industry,2000(11):29−33.] HU Tiejun, YAN Gehua, ZOU Erxin, et al. Development of whole beef emulsified sausage[J]. Meat Industry, 2000(11): 29−33.

[29] 闫海鹏. 不同种类肉肌原纤维蛋白功能特性的研究[D]. 南京:南京农业大学, 2013. [YAN Haipeng. A study on the functional characteristics of different types of meat myofibrillar proteins[D]. Nanjing:Nanjing Agricultural University, 2013.] YAN Haipeng. A study on the functional characteristics of different types of meat myofibrillar proteins[D]. Nanjing: Nanjing Agricultural University, 2013.

[30] 阮雁春, 刘宁海, 杨丹, 等. 超声及干热美拉德反应对大豆分离蛋白功能特性的影响[J]. 食品科技,2021,46(3):225−231. [RUAN Yanchun, LIU Ninghai, YANG Dan, et al. The effect of ultrasound and dry heat Maillard reaction on the functional characteristics of soy protein isolate[J]. Food Technology,2021,46(3):225−231.] RUAN Yanchun, LIU Ninghai, YANG Dan, et al. The effect of ultrasound and dry heat Maillard reaction on the functional characteristics of soy protein isolate[J]. Food Technology, 2021, 46(3): 225−231.

[31] 高菲菲. 牛胃平滑肌加工特性研究[D]. 南京:南京农业大学, 2012. [GAO Feifei. Study on the processing characteristics of bovine gastric smooth muscle[D]. Nanjing:Nanjing Agricultural University, 2012.] GAO Feifei. Study on the processing characteristics of bovine gastric smooth muscle[D]. Nanjing: Nanjing Agricultural University, 2012.

[32] SHEN Y Q, GUO X X, LI X R, et al. Effect of cooking temperatures on meat quality, protein carbonylation and protein cross-linking of beef packed in high oxygen atmosphere[J]. LWT,2022,154:112633. doi: 10.1016/j.lwt.2021.112633

[33] BAYRAKTAROGLU A G, KAHRAMAN T. Effect of muscle stretching on meat quality of biceps femoris from beef[J]. Meat Science,2011,88(3):580−583. doi: 10.1016/j.meatsci.2011.02.021

[34] GORSKA, MAGDALENA, WOJTYSIAK, et al. Importance of intramuscular connective tissue for meat quality[J]. Medycyna Weterynaryjna,2016,72(10):600−603. doi: 10.21521/mw.5577

[35] 王复龙, 高菲菲, 彭增起. pH变换腌制对牛胃平滑肌嫩度、保水性及微观结构的影响[J]. 食品工业科技,2016,37(3):110−113,118. [WANG Fulong, GAO Feifei, PENG Zengqi. The effect of pH change pickling on the tenderness, water retention, and microstructure of bovine gastric smooth muscle[J]. Food Industry Technology,2016,37(3):110−113,118.] WANG Fulong, GAO Feifei, PENG Zengqi. The effect of pH change pickling on the tenderness, water retention, and microstructure of bovine gastric smooth muscle[J]. Food Industry Technology, 2016, 37(3): 110−113,118.

[36] 孙钟雷, 熊玥, 李宇. 胭脂萝卜质地特性分析研究[J]. 中国调味品,2020,45(7):53−58. [SUN Zhonglei, XIONG Yue, LI Yu. Analysis and study on the texture characteristics of rouge radish[J]. Chinese Seasoning,2020,45(7):53−58.] SUN Zhonglei, XIONG Yue, LI Yu. Analysis and study on the texture characteristics of rouge radish[J]. Chinese Seasoning, 2020, 45(7): 53−58.

[37] LI S S, YU Q L, HAN L, et al. Effects of proteome changes on the tenderness of yak rumen smooth muscle during postmortem storage based on the label-free mass spectrometry[J]. Food Research International,2019,116:1336−1343. doi: 10.1016/j.foodres.2018.10.023

[38] 张晨, 王妍, 张丽, 等. 基于聚类分析的牦牛瘤胃精细划分及其蛋白组成和食用品质差异分析[J]. 食品与发酵科技,2018,54(3):117−123. [ZHANG Chen, WANG Yan, ZHANG Li, et al. Fine division of yak rumen based on cluster analysis and analysis of differences in protein composition and edible quality[J]. Food and Fermentation Technology,2018,54(3):117−123.] ZHANG Chen, WANG Yan, ZHANG Li, et al. Fine division of yak rumen based on cluster analysis and analysis of differences in protein composition and edible quality[J]. Food and Fermentation Technology, 2018, 54(3): 117−123.

[39] 窦玉琴, 孙万成, 罗毅皓, 等. 不同部位及地区藏羊肉的肉品质及其组织学特性[J]. 食品研究与开发, 2023, 44(9):59-68. [DOU Yuqin, SUN Wancheng, LUO Yihao, et al. The meat quality and histological characteristics of Tibetan lamb from different parts and regions[J]. Food Research and Development, 2023, 44(9):59-68.] DOU Yuqin, SUN Wancheng, LUO Yihao, et al. The meat quality and histological characteristics of Tibetan lamb from different parts and regions[J]. Food Research and Development, 2023, 44(9): 59-68.

[40] WEI Y C, LI X, ZHANG D Q, et al. Comparison of protein differences between high- and low-quality goat and bovine parts based on iTRAQ technology[J]. Food Chemistry,2019,289:240−249. doi: 10.1016/j.foodchem.2019.03.052

[41] 赵谋, 杨欢欢, 杨莉, 等. 燕麦β-葡聚糖对低盐羊肉肉糜凝胶特性的影响[J]. 食品科学,2023,44(16):159−168. [ZHAO Mou, YANG Huanhuan, YANG Li, et al. Effect of oat β-glucan on the gel characteristics of low-salt mutton mince[J]. Food Science,2023,44(16):159−168.] ZHAO Mou, YANG Huanhuan, YANG Li, et al. Effect of oat β-glucan on the gel characteristics of low-salt mutton mince[J]. Food Science, 2023, 44(16): 159−168.

[42] 吴菊清. 猪肉肌原纤维蛋白乳化特性研究[D]. 南京:南京农业大学, 2017. [WU Juqing. Study on the emulsification characteristics of pork myofibrillar protein[D]. Nanjing:Nanjing Agricultural University, 2017.] WU Juqing. Study on the emulsification characteristics of pork myofibrillar protein[D]. Nanjing: Nanjing Agricultural University, 2017.

[43] 杨华连, 陈莉, 卢红梅, 等. 提取方法对薏仁碎米蛋白氨基酸组成及功能特性的影响[J]. 食品科技,2018,43(11):262−268. [YANG Hualian, CHEN Li, LU Hongmei, et al. The effect of extraction methods on the amino acid composition and functional characteristics of Job's tears broken rice protein[J]. Food Technology,2018,43(11):262−268.] YANG Hualian, CHEN Li, LU Hongmei, et al. The effect of extraction methods on the amino acid composition and functional characteristics of Job's tears broken rice protein[J]. Food Technology, 2018, 43(11): 262−268.

[44] KUNARAYAKUL S, THAIPHANIT S, ANPRUNG P, et al. Optimization of coconut protein deamidation using protein-glutaminase and its effect on solubility, emulsification, and foaming properties of the proteins[J]. Food Hydrocolloids,2018,79:197−207. doi: 10.1016/j.foodhyd.2017.12.031

[45] 郑文雄, 杨榕琳, 水珊珊, 等. 热加工对三种带鱼肌球蛋白功能特性的影响[J]. 食品科学, 2024, 45(7):211-217. [ZHENG Wenxiong, YANG Ronglin, SHUI Shanshan, et al. The effect of thermal processing on the functional characteristics of three types of hairtail myosin[J]. Food Science, 2024, 45(7):211-217.] ZHENG Wenxiong, YANG Ronglin, SHUI Shanshan, et al. The effect of thermal processing on the functional characteristics of three types of hairtail myosin[J]. Food Science, 2024, 45(7): 211-217.

[46] 李小胜, 陈珍珍. 如何正确应用SPSS软件做主成分分析[J]. 统计研究,2010,27(8):105−108. [LI Xiaosheng, CHEN Zhenzhen. How to correctly apply SPSS software for principal component analysis[J]. Statistical Research,2010,27(8):105−108.] LI Xiaosheng, CHEN Zhenzhen. How to correctly apply SPSS software for principal component analysis[J]. Statistical Research, 2010, 27(8): 105−108.

[47] 欧秀琼, 刘作华, 杨飞云, 等. 不同基因型猪肌红蛋白含量的变化规律及其与肉质的关系研究[J]. 养猪,2009(1):27−30. [OU Xiuqiong, LIU Zuohua, YANG Feiyun, et al. A study on the variation pattern of myoglobin content in different genotypes of pigs and its relationship with meat quality[J]. Pig Farming,2009(1):27−30.] OU Xiuqiong, LIU Zuohua, YANG Feiyun, et al. A study on the variation pattern of myoglobin content in different genotypes of pigs and its relationship with meat quality[J]. Pig Farming, 2009(1): 27−30.

下载:

下载:

下载:

下载: