Research Progress on Risk Factors in the Whole Supply Chain of Prepared Livestock and Poultry Meat Dishes

-

摘要: 畜禽肉类预制菜肴是以畜禽肉为主要原料的预包装菜肴,经工业化预加工并包装后在产品标签条件下贮存、运输及销售。因其方便快捷正在受到越来越多消费者的喜爱。畜禽类预制菜肴从原料肉、热加工到包装杀菌的整个生产链条中,可能存在着一些潜在风险因子,包括原料肉带入的兽药残留、热加工产生的有毒有害副产物、食品包装化学材料迁移和微生物污染等。本文围绕原料预处理、烹制加工、包装、灭菌、贮藏和复热六个处理过程,介绍了畜禽肉类预制菜肴的生产链条中存在的食品安全问题种类、来源、危害和研究现状,使其能在生产加工过程中有效规避风险,更全面地预防食品安全问题,为畜禽肉类预制菜肴的工业化发展提供参考意义。Abstract: The prepared livestock and poultry meat dishes are defined as pre-packaged products mainly made of livestock and poultry meat using several processing technologies. After packaging, they need to undergo stored, transported, and sold under the conditions listed on the product label. Customers are becoming more and more enamored with these dishes due to their convenience and speedy production. However, the entire food supply chain, from raw meat to thermal processing to packaging and sterilization, may contain some potential risk factors, including veterinary medication residues from raw meat, hazardous and toxic thermal processing by products, chemical material migration, microbial contamination of food packaging. This paper focuses on six treatment processes: Raw material pretreatment, cooking and processing, packaging, storage, sterilization and reheating. In addition, a description is given of the types, sources, hazards, and research status of food safety problems in the supply chain of prepared livestock and poultry meat dishes. This paper can provide references for the industrial development of prepared livestock and poultry meat dishes since it can aid in the more effective avoidance of food production and processing hazards as well as the more thorough prevention of food safety problems.

-

Keywords:

- livestock and poultry meat /

- prepared dishes /

- whole chain /

- thermal processing /

- food safety

-

预制菜(Prepared Dishes)是指将各类农产品、畜禽肉类、水产品等作为主要原料,辅以调味料等食材,在经过预选、调制等工艺加工后制成的半成品[1]。畜禽肉类菜肴在中国传统饮食中起着重要的作用,是正餐中不可或缺的一部分[2]。中国市场的首批加工预制菜企业约20多年前才崭露头角,随着冷链系统的发展和外卖市场的兴起,预制菜也在不断发展,人们对预制菜的需求激涨,政府也出台了相应政策提供引导作用[3],预制食品产业迎来快速发展,正在成为国内大循环中发挥消费拉动作用的新生力量[4]。

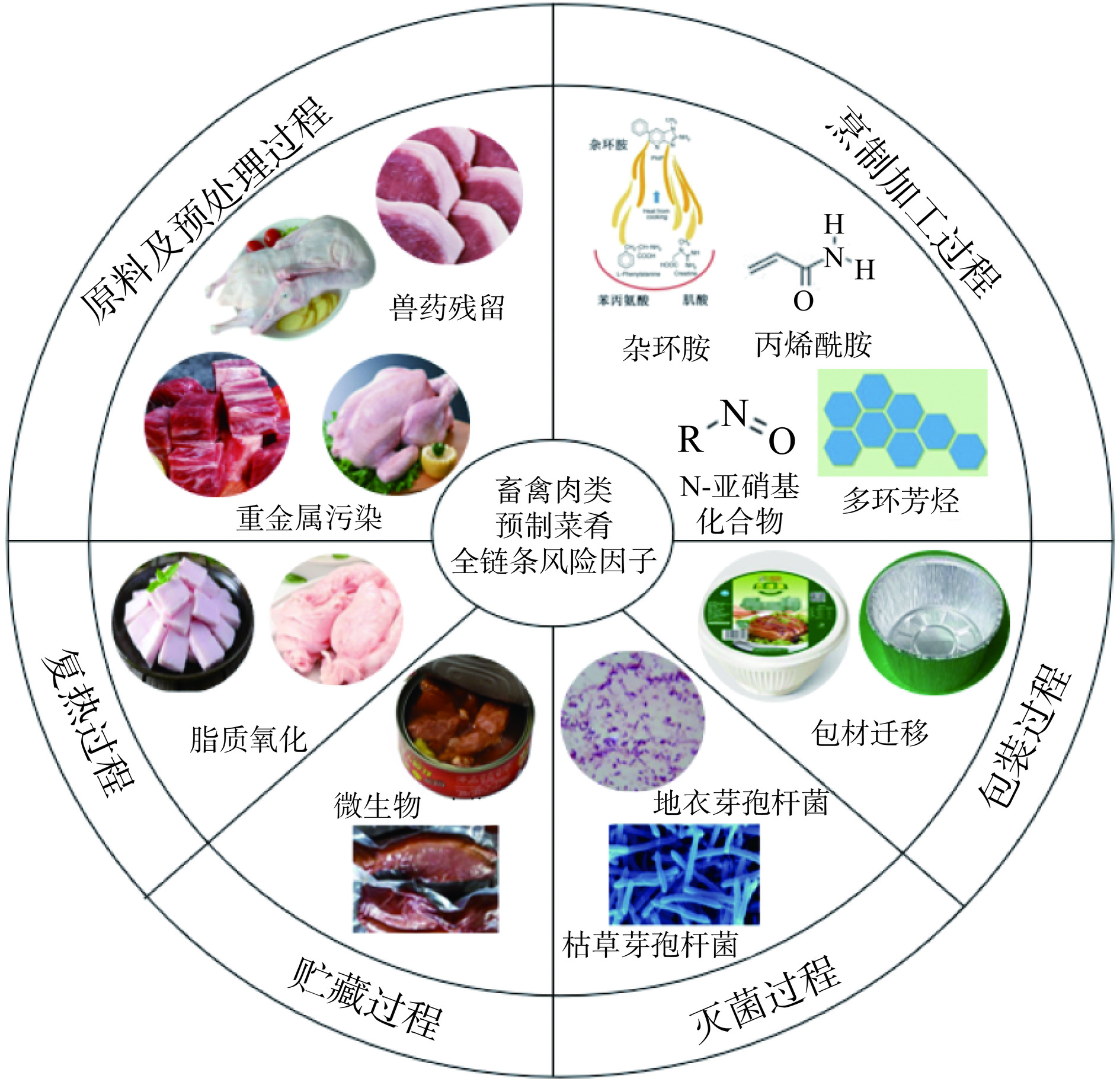

食品安全风险存在于整个食品供应链,从动物的饲养、屠宰、加工到食品的分销与购买,供应链中存在的风险因子与食品安全紧密关联[5]。因此,本文主要围绕畜禽肉类预制菜肴展开论述(图1),从原料肉的宰割和预处理、经烹制加工到包装、灭菌、再到贮藏与复热过程,分六个部分总结了畜禽肉类预制菜肴全链条风险因子的种类、来源、危害和研究现状,并简要介绍了现有的标准,系统梳理了畜禽类预制菜全链条风险因子相关进展,期望能够以安全为着力点赋能中国畜禽类预制菜产业发展。

1. 原料及预处理过程

畜禽肉类预制菜一般由原料肉、素菜、香辛料和调味料组成。原料肉需经过清洗、屠宰、切割、腌制等预处理过程。从原料肉中带入及预处理过程中的风险主要有兽药残留和重金属污染。

1.1 兽药残留

在畜牧业中常给动物饲喂或注射兽药产品以防止传染病或疾病,以此最大限度地提高动物的免疫力和繁殖能力,从而提高肉类产品的营养价值[6]。但当部分不法生产者片面追求收益,超剂量使用兽药或不按规定使用违禁药物时,就会导致动物源性食品中出现兽药残留,通常以原药、残留物和代谢物的形式存在[7]。根据世界卫生组织食品添加剂联合专家委员会的报告,目前食品中存在着超过120种兽药残留物[8],这些残留物可能会引起急性或慢性中毒、诱发过敏反应和细菌抗药性,并造成致畸、致癌、致突变的“三致”作用和激素样作用。

如表1所示,目前绝大部分鲜肉食材中的兽药残留物水平都低于定量限,而畜禽肉的不合格现象主要是由不遵守兽药管理条例造成,特别是在氯霉素、氧氟沙星、磺胺类、恩诺沙星这4种兽药的违规使用上尤为突出。目前在部分鸡肉和猪肉样品中仍检出禁限兽药甲硝唑的残留[12−13],这表明动物源性食品中依然存在甲硝唑暴露风险,因此开展人体生物监测变得至关重要。同样,YOSHIKAWA等[15]也运用了UPLC-MS/MS方法,对东京市面上的部分可购鸡肉产品进行监测,发现兽药残留检出比超过11%,该数据表明兽药的违法违规现象仍存在,需加强管控及相关法规的执行力度。对于生产者,可以通过水焯、热烫和炸制等处理有效降低畜禽肉类中兽药残留量,在制成预制菜肴的高温烹饪过程中,可以破坏兽药分子的结构使其失去药效。另外,通过冷藏与冻存的方式也能有效降低兽药残留量[16]。

表 1 我国畜禽肉中兽药残留检测情况Table 1. Detection of veterinary drug residues in livestock and poultry meat in China样品种类 检测方法 合格率(%) 不合格指标 国家标准 参考文献 猪肉、牛肉、羊肉 − 99.1 氯霉素、磺胺类总量、恩诺沙星、

氯丙嗪、喹乙醇代谢物、克伦特罗GB 2707-2016 [9]

鸡肉、鸭肉− 95.1 氯霉素、磺胺类总量、恩诺沙星、土霉素、多西环素、氧氟沙星、挥发性盐基氮、五氯酸钠、尼卡巴嗪残留标志物 鸡肉 UPLC-MS/MS − 恩诺沙星、五氯酚 − [10] 猪肉 LC-MS 98 土霉素 − [11] 猪肉、鸡肉、牛肉、羊肉 HPLC-MS/MS 96.7 甲硝唑 SN/T 1626-2019 [12] 猪肉 LC-MS/MS 97.3 甲硝唑 GB 31650-2019 [13] 鸡肉 LC-MS/MS 98.6 甲硝唑 卤猪肉 UPLC-MS/MS 100 − − [14] 1.2 重金属污染

重金属是农业生态系统中一类具有潜在危害的化学污染物,畜禽肉类中的重金属残留是一大食品安全问题,来源主要是工业生产和汽车尾气中含重金属的废水和粉尘,进入土壤后在矿区和河流下游土壤中大量积累[17],且不被土壤中的微生物分解,所以会污染牲畜、家禽饲料,再通过食物链进入到人体,很难被分解或代谢排出,当长期积累后其毒性会对人体造成严重损害[18],对人畜的肝脏、肾脏及神经中枢造成的危害可能长达几十年。因此,杜绝畜禽肉重金属污染是保障畜禽肉类预制菜肴中最基础且必不可缺的环节,研究畜禽肉重金属残留的原因和治理措施具有重要意义。

通过我国内蒙古地区2019~2021年畜禽肉抽检结果的采集,发现羊肉和鸡肉中镉元素的超标率更高[19],且鸡肉的重金属超标比例更大[20]。张琳等[18]和杨丽等[21]的调查结果也证实了畜禽肉中铅和铬元素污染率更高这一观点,另外还得出猪肉重金属污染指数最高的结论,这说明我国某部分养殖场还存在着重金属污染,需要提高生产者自我规范意识和加强监管力度。长期食用含铅食物会导致动物体内钙缺乏,影响骨骼发育,目前还没有有效解决动物铅污染的处理措施。有学者采用电感耦合等离子质谱法,对广州市售畜禽肉中9种重金属含量进行测定,发现铅、镉、砷、铬4种有害金属元素均低于限量值,其余5种重金属元素含量由低到高排序为:镍、钴、锰、铜、锌,其中镍在鸭肉、鸽肉、鸡肉这三种禽肉中均无检出[22]。段玉林等[23]在2021年肉制品重金属研究报告表明,我国仍有肉制品重金属污染的可能性,在肉制品的质量控制中可以重点控制镉、汞、铅、铬和砷元素,需时刻保持警惕。

当畜禽类原料肉被重金属残留污染,将会延续积累至预制菜肴中,进一步影响到加工和食用,被人体摄入后会造成危害。为避免因过量摄入畜禽肉预制菜肴中的重金属残留而造成危害,需要积极预防和控制,加强供应链管理,并定期对畜禽肉中重金属含量进行监测,以降低受污染的可能性。

2. 烹制加工过程

畜禽原料肉可以制作成各式各样的菜肴,需经过油炸、烘烤、蒸煮和烟熏等不同烹制加工方式,该过程也是“预制”的过程。然而,在此过程中,不同的烹制加工方式可能会产生不同的副产物,如杂环胺、丙烯酰胺、亚硝酸盐和多环芳烃等,这些加工伴生危害物是畜禽肉类预制菜肴风险因子的重要组成部分,会增加人体患多种癌症的风险,严重危害消费者的健康,产生不可逆的危害。

2.1 杂环胺

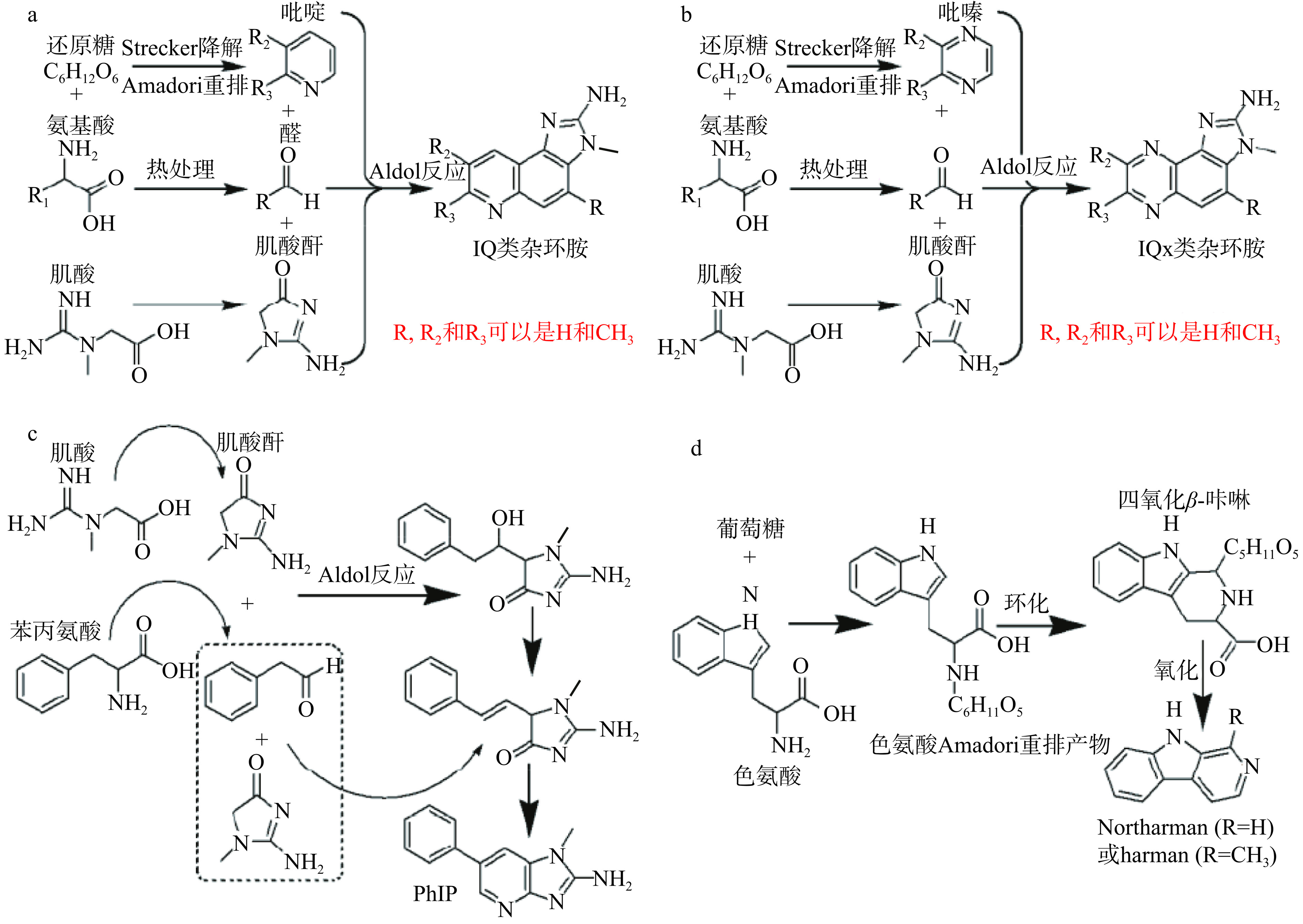

杂环胺(Heterocyclic Aromatic Amines,HAAs)是一类由碳、氢、氮原子构成的杂环芳香烃类化合物的总称,主要在高温加工蛋白质丰富的食物过程中产生(如煎、炸、烤等)。HAAs的生成与自由基引起的脂质氧化和蛋白质氧化有关,它们是蛋白质和氨基酸的热解产物,这些物质被认为具有致癌和致突变的潜在风险。因此若摄入过量,可能会对人体健康构成威胁[24]。目前已经鉴定出超过30种HAAs,常见的几种生成途径如图2所示。

有学者通过HPLC-MS/MS检测了五种不同的HAAs,结果表明烤制的鸡胸肉比鸡腿产生的HAAs数量更多[26],由此可推测,即使在相同的加工条件下,不同部位的鸡肉会产生不同数量的HAAs,因此在预制菜肴的原料肉选择阶段,可以按需选取不同部位的肉为原料进而控制预制菜HAAs的生成量。ZHOU等[27]研究了不同烹调条件对杂环胺形成的影响,发现烹饪时间、烹饪温度和重复烹饪次数与牛肉样品中的HAAs含量呈正相关关系,且当红烧牛肉被炖煮20次时,HAAs的含量最高,达到21.43 ng/g。同样,在不同的油炸牛肉饼中测得HAAs含量会随油炸温度、时间、肌脂比和盐分含量的增加而增加,用葵花籽油炸制时产生HAAs总量最高[28]。此研究提出烹饪条件的选择对牛肉加工过程中HAAs的生成量有很大影响,高温、长时间烹饪和反复加热都会促进HAAs的生成,后续可更深入的研究不同食用油品加工对肉类HAAs生成影响,为畜禽肉类预制菜肴的加工工艺提供建议。除此之外,有学者通过添加外源物的方式,达到降低HAAs含量的目的,有研究表明在220 ℃的温度条件下,添加0.5%的茶多酚可减轻烤羊肉馅饼中的HAA形成[29]。

2.2 丙烯酰胺

丙烯酰胺(Acrylamide,AM)是一种无色无味的有毒片状晶体,化学式为C3H5NO,属于食源性化学毒物[30],常在各种热加工食品中出现,具有神经毒性和遗传毒性,并且已经被国际癌症研究机构(International Agency for Research on Cancer,IARC)列为2A类致癌物质[31]。

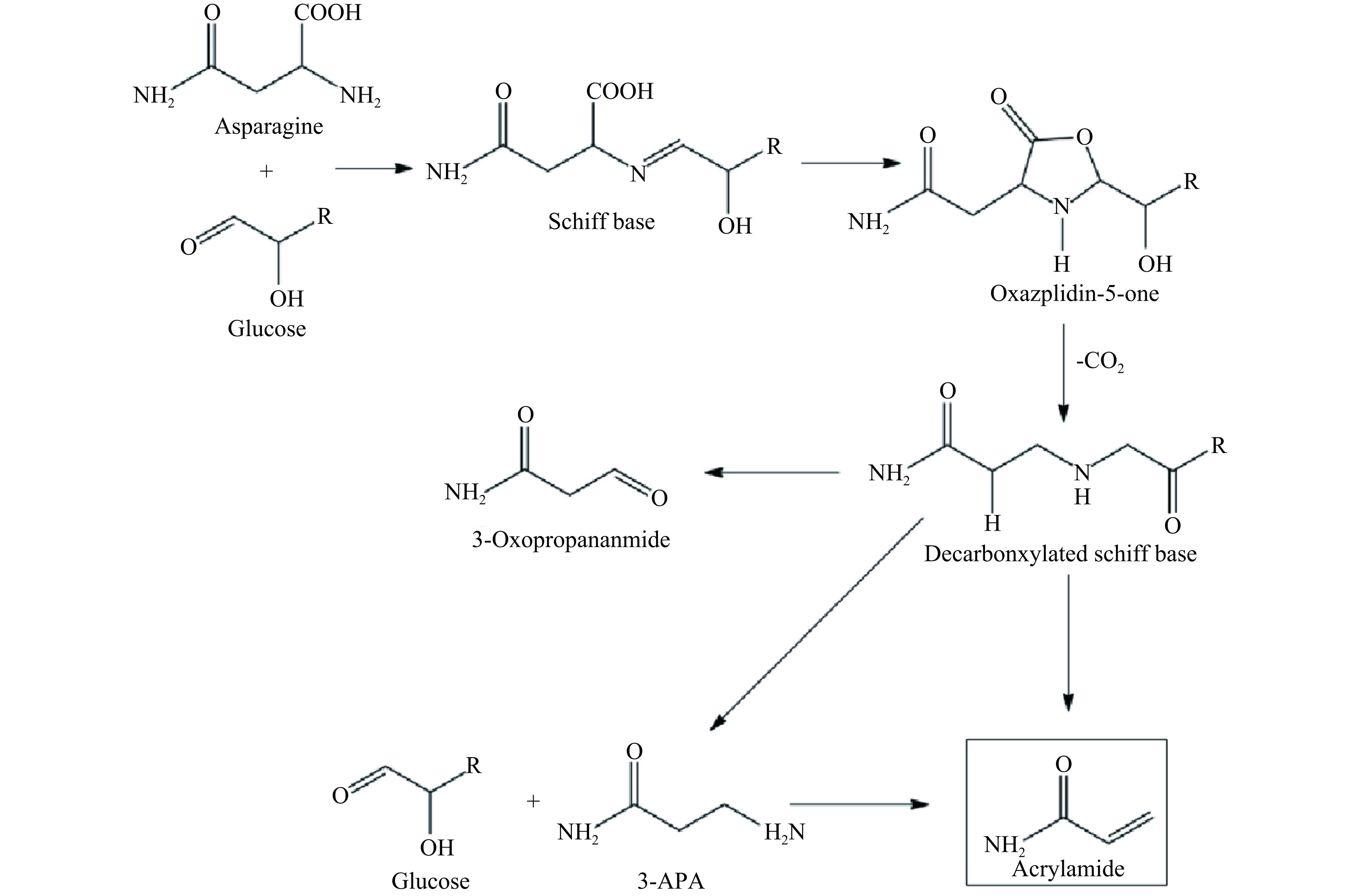

有学者在热加工食品的研究中发现,AM主要的形成途径是美拉德反应(图3)[32],而美拉德反应与畜禽肉类预制菜肴的风味、色泽和营养密切相关。美拉德反应本质上就是富含碳水化合物的食品在高温下加热后的还原糖和游离氨基酸的相互作用。AM在食品中的存在较为普遍,能够通过饮食摄入,以及经口鼻和皮肤途径被人体吸收,一旦进入人体,可能会引发神经系统的毒性反应[33],过量摄入甚至会危害人体的健康和安全,是一种重要风险因子[34]。

仅添加食用盐的牛肉碎在烧烤、煎炸和烘烤过程中AM的形成量上升,但总体含量较低[35]。对比鲜肉和水焯肉的差异,动态监测到AM在红烧肉的烹饪过程中的生成,尤其是加入酱油、糖、料酒等调味料后,AM含量达到峰值,为42.4 μg/kg[36]。基于这些发现可推测除热加工外,调味料也会促进猪肉烹饪过程中AM的生成。而调味料作为菜肴中不可或缺的辅料之一,其量若不足,不仅会影响菜肴的整体风味,还可能导致后续制备成预制菜肴后出现防腐性不足的问题。为控制食品中的AM,应避免过高的烹制温度和过长的烹饪时间,预防AM最佳的方法包括时间/温度优化、酶处理、酵母处理、脉冲电场、超声波、真空烘烤和辐照等[37]。近年来,添加外源物以实现控制AM的研究日益增多,如苹果渣被用作抑制AM的生成[38],黑果枸杞具有对AM诱导的神经毒性的潜在神经保护作用[39],其中多酚类物质起到了主要作用,这些方法在消除食品中的AM方面表现出很强的功效。

2.3 亚硝酸盐

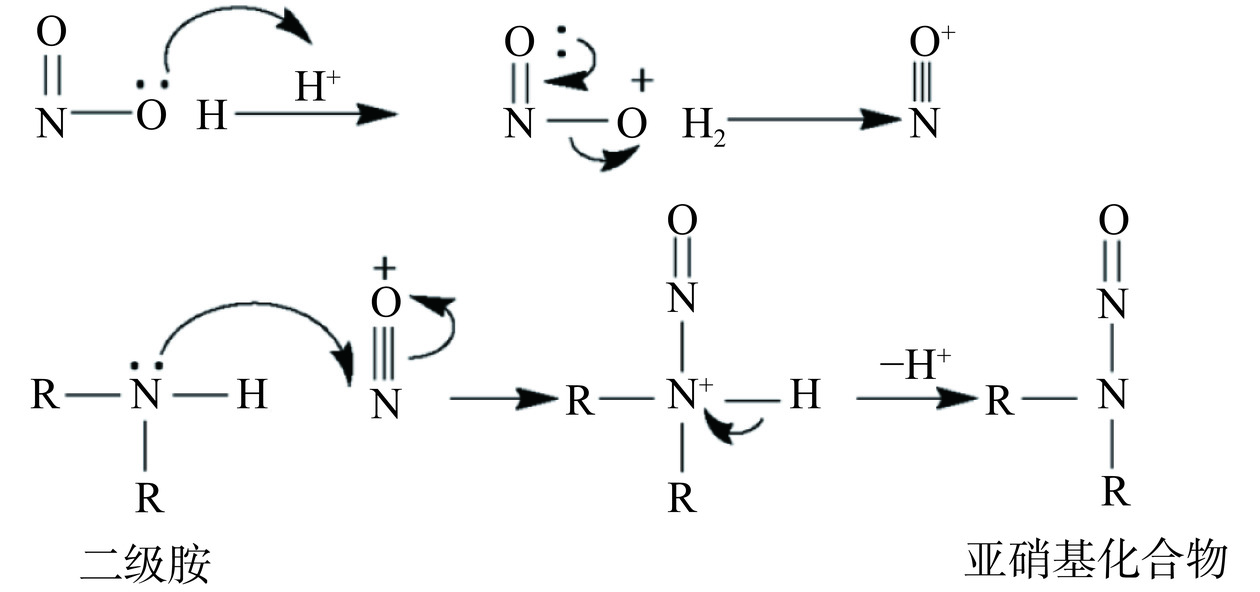

亚硝酸盐(Nitrite,Nit)是一类无机化合物的总称,主要包括亚硝酸钠和亚硝酸钾,在肉制品中常作为发色剂和防腐剂使用,用于抑制肉制品中脂质和蛋白质的氧化,并限制致病微生物的生长[40]。畜禽肉类预制菜肴含丰富的脂肪和蛋白质,但当亚硝酸盐在酸性条件下,与二级胺或三级胺相互作用生成N-亚硝基化合物(N-nitroso Compounds,NOCs)(图4)[41],有潜在的致癌风险[42],危害人体健康。此外,烧烤及烟熏类肉制品加工过程中产生的烟雾含有的大量气态氮氧化物,在一定条件下会转化为NOCs[43]。

许多学者对市售畜禽肉类食品中的亚硝酸盐含量进行测定,并研究其安全性,发现仍然有部分熟肉制品商户超限量使用亚硝酸盐的现象,参照国家标准GB 2760-2014可知不达标率为6.6%(≤30 mg/kg)[44−45],说明对于食品添加剂的正确使用仍是食品安全领域的重要课题。此外,不同的加工方式也会对亚硝酸盐含量有影响,腌制和滚揉工艺会导致其升高,而加热处理后又降低,但对比鲜肉时期总体呈上升趋势[46]。在畜禽肉类食品的加工与贮藏中,降低亚硝酸盐含量的最佳方法成为一大研究重点,许多学者都作出了不同的尝试方法。在鸭肉香肠的发酵加工过程中,接种复合发酵剂能有效降低Nit含量,相比不接种的组降低了1.33 mg/kg[47]。黄苓等[48]研究制作一种零添加亚硝酸盐的腊肉,使用红曲红和甜菜红当发色剂,并添加可降解亚硝酸盐的益生菌以降低其含量,得出最优组腊肉产品的亚硝酸盐质量分数仅为11.39 mg/kg,比市售腊肉的大约低86%。这种创新方法为畜禽肉的加工提供了一种新的解决方案,以减少亚硝酸盐的健康风险,同时也满足了市场对天然健康食品的需求。

2.4 多环芳烃(PAHs)

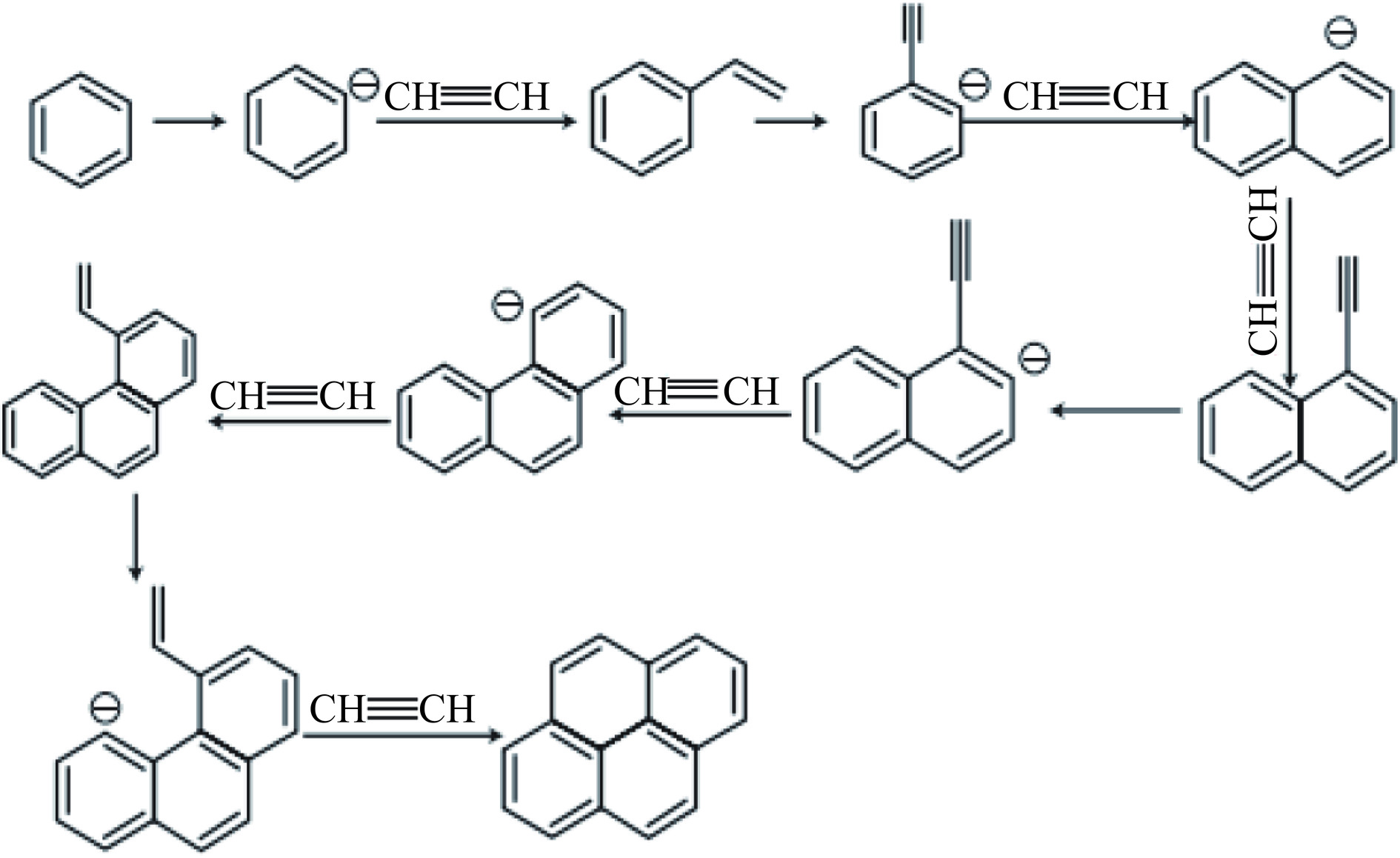

多环芳烃(Polycyclic Aromatic Hydrocarbons,PAHs)指两个或两个以上的苯环和稠环连接而成的芳香族化合物,是熏烤肉类产品中典型的持久性有机污染物,PAHs生成过程如图5所示,对人体有致畸、致癌、致突变的“三致”效应。研究表明,除吸烟和部分职业因素外,膳食已成为人群暴露于多环芳烃的主要因素。

加工肉类产品中PAHs的形成与不同的烹饪方式和加工技术有关,如烧烤、烟熏、干燥、欧姆红外烹饪等,PAHs的含量取决于产品与热源的距离、燃料来源、加工程度、烹饪时间或烹饪方法等因素[50]。在常见的两种加热方式中,烟熏与烧烤相比会导致更高的PAHs污染,使用皂化提取和SPE方法对PAHs的检测和定量最为有效[51]。有学者研究了不同肉丸子在油炸过程中的PAHs形成规律,发现在同等时间下,连续性油炸的方式产生的PAHs量均大于间歇性油炸条件[52],因此在后续油炸工艺中,可以选择初炸再复炸以降低PAHs的生成量,同时保持更酥脆的口感;魏健等[53]研究了变温烤制对新疆馕坑烤肉PAHs含量的影响,采用了气相色谱-质谱法(Gas Chromatography Mass Spectrometry,GC-MS)进行测定,发现高温组、低温组、对照组分别检测出多环芳烃类物质12、9、8种,说明馕坑烤肉这种热加工方式会产生多环芳烃类物质,其中含量最高的高温组多环芳烃总含量达427.45±27.84 ng/g,显著高于其余两组,但三组馕坑烤肉中均未检测出IARC认定的一级致癌物质苯并[a]芘,说明馕坑烤肉中的有害物质致癌作用有限,可以适当采取措施防控。

3. 包装过程

包装是生产链条中必不可缺的一环,在完成热加工后需加以包装才真正成为预制菜肴。畜禽肉类菜肴的多样化也关乎到相应包装材料的多样化,不同的菜肴在物理和机械性能、阻隔性能和食品安全方面都有各自的需求[54],环境不同包装材料的适用性也存在差异。食品包装材料中的有毒有害化合物,会通过渗透、扩散、挥发、释放等方式转移到食品中,这种在包装和食品之间的转移被称为"迁移"。化学物质的迁移是畜禽肉类预制菜肴包装过程中最主要的风险因子,包装材料选择不当可能导致单体或添加剂迁移对产品造成污染,从而直接影响预制菜肴的品质与安全[55]。

食品包装材料不断在更新改进,最大的原因是包材迁移的危害影响深重。食品包装上常有用于提供有关品牌、成分和营养价值信息的印刷油墨,而印刷油墨的成分迁移将直接或间接地对人体生长激素代谢及骨骼生长产生影响;用于密封包装的粘合剂在包装或贮藏过程中也会迁移到食品中,会刺激人的五官和皮肤;微量金属的迁移会引起慢性和急性症状包括头晕、恶心、腹泻、呕吐、食欲不振、睡眠障碍和受孕率下降,还和心血管疾病、生长受抑制、神经和免疫系统失调、生育能力受损、自然流产增加和婴儿死亡率升高有关[56]。预制菜通常含有醋、酱油和油脂等成分,这些物质与塑料包装接触时,可能会促使邻苯二甲酸酯类塑化剂从塑料中迁移至食物内[57]。付清等[58]通过6大类外卖餐具探究16种合成酚类抗氧化剂(Synthetic Phenolic Antioxidants,SPAs)的迁出情况,发现所有外卖餐盒中都广泛检出SPAs,在食品添加和包装材料转移的双重作用下,食品中SPAs的污染现况不清,人群暴露风险未知,该类物质具有内分泌干扰毒性、神经毒性、生殖毒性和发育毒性。

在过去几十年中,预制肉品包装的效率和功能得到了显著的提升,这归功于材料、方法和机械技术的改进。与此同时,食品包装材料也在不断创新发展,从传统的聚丙烯、聚乙烯等塑料包装到如今研究较多的可食性薄膜[59]、可生物降解薄膜[60]、纳米复合薄膜[61]等,新的肉类预制菜肴包装理念不断涌现,能限制包装内环境和把控产品质量的智能包装正在引起越来越多人的关注。

4. 灭菌过程

由于畜禽肉含有丰富的脂肪和蛋白质,易受微生物污染,因此在预制菜肴包装好后,还需进行灭菌程序,才能安全保质地进行下一步分销。对易污染的微生物菌群进行控制,针对性地采取合适的灭菌方式。当灭菌不彻底或包装密封不严会导致微生物进入,缩短食品的保质期并引起腐败。一般来说,预制菜肴工业化生产中的灭菌方式主要有巴氏灭菌、超高压杀菌、超高温瞬时杀菌、紫外线杀菌、臭氧杀菌、辐照灭菌和微波杀菌等。

在一项关于主要产气微生物的研究中,选取某企业高投诉率的产品进行检测,确定了胀袋红烧肉中主要产气微生物为弗氏柠檬酸杆菌(Citrobacter freundii)[62],同理发现引起牛肉方便菜肴食品胀袋的主要微生物为地衣芽孢杆菌(Bacillus licheniformis)和枯草芽孢杆菌(Bacillus subtilis)[63]。综上,可以推断造成畜禽肉类预制菜肴微生物污染的主要菌群是芽孢杆菌属。

灭菌过程的风险因子主要由灭菌不完全导致畜禽肉腐败产生,想要降低食品腐败风险,必须确定引起腐败的主要微生物种类,按照高腐败潜力微生物的特点进行针对控制,也就是说要找到杀灭芽孢杆菌属的最适条件,从而达到防止腐败、延长食品保质期的目的。此前,有学者采用了超高压杀菌法结合Box-Behnken试验,结果表明随着压强、时间和水温的增加,熟制鸭肉中的菌落总数会减少[64]。方春玉等[65]研究工业化生产四川小煎鸡菜肴,结果证明121 ℃灭菌15 min是最佳的灭菌条件,在此处理下没有检测到致病菌,符合既定的微生物指标,能够较好保持鸡肉品质的同时把保质期延长至90~100 d,满足了工业化菜肴长期贮藏的灭菌要求。为探究回锅肉在工业化生产中灭菌方法的选择,从感官、颜色、质地、脂肪氧化和产品保质期等方面比较了食品工业中常用的三种消毒方法,即巴氏灭菌、116 ℃灭菌和121 ℃灭菌。实验结果表明,121 ℃高温灭菌有利于抑制脂肪氧化和延长保质期,但对口感有一定程度上的负面影响[66],此结论与前述学者的结论相符。目前灭菌流程尚未有国家的标准化要求,现阶段畜禽肉类预制菜肴的发展仍缺少较权威的灭菌方案,以减少食品安全风险,确保预制菜行业健康有序发展。

5. 贮藏过程

完成包装与灭菌后,需要在适当的条件下贮藏才能运输到各大批发商城或零售店铺。据市场调查,肉类预制菜常用的贮藏条件为常温、4 ℃冷藏和−18 ℃冷冻。在不同温度的贮藏过程中,最主要的风险因子是微生物的繁殖及畜禽肉中脂肪的氧化变质。对三组中式预制菜肴在冷藏(4 ℃)和常温(25 ℃)两种不同贮藏温度下的理化指标进行研究,以硫代巴比妥酸值(Thiobarbituric Acid,TBA)、酸价(Acid Value,AV)和过氧化值(Peroxide Value,POV)作为评判标准,发现两组的指标均随着贮藏天数的增加而升高,且两处理组有显著差异(P<0.05)[67]。

4 ℃贮藏温度能够显著降低样品贮藏过程中脂质降解的二级产物含量,通过降低脂肪酸氧化降解的速度,可以有效减少游离脂肪酸和过氧化物的积累,从而延缓样品的脂质氧化进程。同样,有学者将碗式包装和真空包装的萝卜炖牛腩经微波巴氏联合杀菌后,置于4 ℃下冷藏贮藏,发现二者在20余天后菌落总数超标,保质期较短,除包装原因外,猜测是因为4 ℃不足以抑制残存的孢子的生长[68],由此可知4 ℃的贮藏温度能减少脂肪氧化,但在此贮藏温度下食品货架期较短。−18 ℃冷冻是目前最为有效的肉类预制菜保质贮方法,最大优点是可以降低水分活度,可以在不借助任何防腐剂和添加剂的基础上使食品品质得到最大限度保留[69]。食品在冻藏的过程中,水分通常会流失,蛋白质也会变性,在保证防腐的同时,可以通过添加磷酸盐等保水剂的方式改善质构特性,从而提升食品的口感[70]。

6. 复热过程

畜禽肉类预制菜肴经运输分售到消费者手中,由消费者购买后进行复热处理再食用,才算真正走上餐桌。复热是指对贮藏后的熟制食品进行二次加热,常见的复热方法有气蒸、水煮、煎炸、微波等。在复热过程中,畜禽肉类丰富的脂肪发生氧化,会在一定程度上影响肉品的质量,而加工方式是影响脂肪氧化的一个重要因素。通常用不饱和脂肪酸的氧化产物醛类(Thiobarbituric Acid,TBA)来作为评判脂肪氧化程度的指标,TBA值表示脂肪二级氧化产物的数量,值越高说明脂肪次级氧化程度越高[71]。

当TBA>0.5 mg MDA/kg时,脂肪开始氧化。由表2可以看出,在猪肉饼的微波复热中,TBA值检测结果为0.37~2.11 mg/100 g。微波加热会使食物中磷脂的多不饱和脂肪酸减少,加快脂肪氧化,从而引起TBA值的升高,因此微波加热具有短时高效但会加速脂肪氧化的特点,而水浴复热恰好可以有效避免这一点,尤其是低温长时水浴,是较为推荐的复热方式,据此推断复热的方式对脂肪氧化的影响主要与加热温度有关。此外,由表2样品的多样性与TBA值的联系,发现规律性不大,推断TBA值与肉的种类关联性不大,未来可以尝试做多种样品完善调查,以规避不相关因素的影响。随着的畜禽肉类预制菜肴快速发展,采用适当的复热方法对恢复产品原有的独特食用营养价值至关重要。

表 2 不同复热方式对畜禽肉类预制菜肴TBA值的影响Table 2. Influence of different reheating methods on TBA values of livestock and poultry meat prepared dishes7. 结论与展望

尽管畜禽肉类预制菜肴凭借其诱人的色泽风味和快速便捷的特性深受人们的青睐,然而,在畜禽肉原材料加工包装至预制菜及运输分销全链条中,出现的种种有害物质所带来的食品安全问题不可轻视。畜禽肉拥有多样化的源头,兽药残留和重金属残留作为原料肉带入的风险因子,若残留量高于限定标准,则会经食物链进入人体而对健康产生威胁。畜禽肉营养成分丰富,在制备成预制菜肴的高温过程中发生一系列化学反应,生成的各种热加工危害物包括HAAs、AM、NOCs等也需引起重视。在食品包装材料的不同选择引起的化学物质迁移、灭菌不够彻底造成的微生物污染、以及复热前的脂肪氧化酸败,都是畜禽肉类预制菜肴生产链条中可能出现的风险因子。这些现存的风险因子来源广泛,危害程度不一,轻则引发食源性疾病,严重的还会导致死亡。由此可知畜禽肉类预制菜肴的发展仍存在许多方面的问题,需要进行多方面的深入调查及针对性解决。

随着人们对食品安全重要性觉悟和要求的提高,以及市场需求量的扩大,传统加工方式已不能完全满足人们的要求,食品工业化生产逐渐代替传统加工方式,预制菜肴并正在向高标准、富营养、智能化的方向发展。基于市场对畜禽肉类预制菜肴的需求,同时国家尚未推出相关的标准化政策,因而对其整个供应链的潜在风险因子进行梳理和分析格外关键。本文期望在未来畜禽肉类预制菜肴能够最大程度保留菜肴的原汁原味,以及畜禽肉类原有的营养价值,针对全链条过程中的每一环节,从源头开始控制好不同类型预制菜肴的生产条件,以保证出厂产品的品质安全。

-

表 1 我国畜禽肉中兽药残留检测情况

Table 1 Detection of veterinary drug residues in livestock and poultry meat in China

样品种类 检测方法 合格率(%) 不合格指标 国家标准 参考文献 猪肉、牛肉、羊肉 − 99.1 氯霉素、磺胺类总量、恩诺沙星、

氯丙嗪、喹乙醇代谢物、克伦特罗GB 2707-2016 [9]

鸡肉、鸭肉− 95.1 氯霉素、磺胺类总量、恩诺沙星、土霉素、多西环素、氧氟沙星、挥发性盐基氮、五氯酸钠、尼卡巴嗪残留标志物 鸡肉 UPLC-MS/MS − 恩诺沙星、五氯酚 − [10] 猪肉 LC-MS 98 土霉素 − [11] 猪肉、鸡肉、牛肉、羊肉 HPLC-MS/MS 96.7 甲硝唑 SN/T 1626-2019 [12] 猪肉 LC-MS/MS 97.3 甲硝唑 GB 31650-2019 [13] 鸡肉 LC-MS/MS 98.6 甲硝唑 卤猪肉 UPLC-MS/MS 100 − − [14] 表 2 不同复热方式对畜禽肉类预制菜肴TBA值的影响

Table 2 Influence of different reheating methods on TBA values of livestock and poultry meat prepared dishes

-

[1] 赵靓琳. 预制菜行业现状及问题研究[J]. 现代营销(经营版),2021(9):146−147. [ZHAO Jinglin. Research on the current situation and problems of the pre-prepared vegetable industry[J]. Modern Marketing (Business Edition),2021(9):146−147.] ZHAO Jinglin. Research on the current situation and problems of the pre-prepared vegetable industry[J]. Modern Marketing (Business Edition), 2021(9): 146−147.

[2] 吴晓蒙, 饶雷, 张洪超, 等. 新型食品加工技术提升预制菜肴质量与安全[J]. 食品科学技术学报,2022,40(5):1−13. [WU Xiaomeng, RAO Lei, ZHANG Hongchao, et al. Quality and safety improvement of premade cuisine by novel food processing technologies[J]. Journal of Food Science and Technology,2022,40(5):1−13.] doi: 10.12301/spxb202200904 WU Xiaomeng, RAO Lei, ZHANG Hongchao, et al. Quality and safety improvement of premade cuisine by novel food processing technologies[J]. Journal of Food Science and Technology, 2022, 40(5): 1−13. doi: 10.12301/spxb202200904

[3] 赵福振, 杨格, 杨铭铎, 等. 发展预制菜产业的意义与前景: 基于预制菜的食品属性[J]. 中国调味品,2022,47(10):215−220. [ZHAO Fuzhen, YANG Ge, YANG Mingduo, et al. Significance and prospect of developing pre-made food industry: Based on the properties of pre-made food[J]. China Condiment,2022,47(10):215−220.] doi: 10.3969/j.issn.1000-9973.2022.10.042 ZHAO Fuzhen, YANG Ge, YANG Mingduo, et al. Significance and prospect of developing pre-made food industry: Based on the properties of pre-made food[J]. China Condiment, 2022, 47(10): 215−220. doi: 10.3969/j.issn.1000-9973.2022.10.042

[4] 王雪娇. 预制食品对食物供应减损增效的促进作用研究[J]. 价格理论与实践, 2022(12):159−163. [WANG Xuejiao. Study on promoting effect of prepared food on food supply loss reduction and efficiency improvement[J]. Price:Theory & Practice, 2022(12):159−163.] WANG Xuejiao. Study on promoting effect of prepared food on food supply loss reduction and efficiency improvement[J]. Price: Theory & Practice, 2022(12): 159−163.

[5] 邓云, 王华. 供应链视角下食品安全风险因子分析[J]. 江苏商论,2019(10):3−9. [DENG Yun, WANG Hua. Analysis of food safety risk factors from the perspective of supply chain[J]. Jiangsu Commercial Forum,2019(10):3−9.] doi: 10.3969/j.issn.1009-0061.2019.10.001 DENG Yun, WANG Hua. Analysis of food safety risk factors from the perspective of supply chain[J]. Jiangsu Commercial Forum, 2019(10): 3−9. doi: 10.3969/j.issn.1009-0061.2019.10.001

[6] 刘丽娜. 浅谈动物产品兽药残留的危害及对策[J]. 中国畜牧兽医文摘,2018,34(1):24. [LIU Lina. The hazards of veterinary drug residues in animal products and countermeasures[J]. Chinese Abstracts of Animal Husbandry and Veterinary Medicine,2018,34(1):24.] LIU Lina. The hazards of veterinary drug residues in animal products and countermeasures[J]. Chinese Abstracts of Animal Husbandry and Veterinary Medicine, 2018, 34(1): 24.

[7] LI Xiaowei, GUO Ping, SHAN Yawen, et al. Determination of 82 veterinary drugs in swine waste lagoon sludge by ultra–high performance liquid chromatography–tandem mass spectrometry[J]. Journal of Chromatography A,2017,1499:57. doi: 10.1016/j.chroma.2017.03.055

[8] 王俊菊, 史艳艳, 侯慧文. 我国动物性食品中兽药残留的现状、问题及对策[J]. 中国动物保健,2021,23(3):5,7. [WANG Junju, SHI Yanyan, HOU Huiwen. Current situation, problems and countermeasures of veterinary drug residues in animal food in China[J]. China Animal Health,2021,23(3):5,7.] WANG Junju, SHI Yanyan, HOU Huiwen. Current situation, problems and countermeasures of veterinary drug residues in animal food in China[J]. China Animal Health, 2021, 23(3): 5,7.

[9] 吕冰峰, 刘敏, 裴新荣. 2018年中国畜禽肉安全问题调查分析[J]. 食品安全质量检测学报,2019,10(17):5668−5673. [LÜ Bingfeng, LIU Min, PEI Xinrong. Investigation and analysis on the food safety of raw livestock meat and poultry in China in 2018[J]. Journal of Food Safety and Quality,2019,10(17):5668−5673.] LÜ Bingfeng, LIU Min, PEI Xinrong. Investigation and analysis on the food safety of raw livestock meat and poultry in China in 2018[J]. Journal of Food Safety and Quality, 2019, 10(17): 5668−5673.

[10] 许均图, 陈德斌, 陈燕, 等. Captiva EMR-Lipid小柱净化-超高效液相色谱串联质谱法快速测定鸡肉中12种兽药残留[J]. 现代食品,2022,28(23):151−154. [XU Juntu, CHEN Debin, CHEN Yan, et al. Determination of veterinary drug residues in chicken by ultra-performance liquid chromatography tandem mass spectrometry[J]. Analysis and Testing,2022,28(23):151−154.] XU Juntu, CHEN Debin, CHEN Yan, et al. Determination of veterinary drug residues in chicken by ultra-performance liquid chromatography tandem mass spectrometry[J]. Analysis and Testing, 2022, 28(23): 151−154.

[11] 邓宁妍. 鲜猪肉中兽药残留和重金属污染的分析及风险控制研究[D]. 长沙:湖南农业大学, 2022. [DENG Ningyan. Analysis and risk control of veterinary drug residues and heavy metal pollution in fresh pork[D]. Changsha:Hunan Agricultural University, 2022.] DENG Ningyan. Analysis and risk control of veterinary drug residues and heavy metal pollution in fresh pork[D]. Changsha: Hunan Agricultural University, 2022.

[12] 李宁, 肖琎, 王雪松, 等. 高效液相色谱-串联质谱法同时测定动物源性食品中15种禁限兽药残留[J]. 中国饲料,2023(2):97−100. [LI Ning, XIAO Jin, WANG Xuesong, et al. Simultaneous determination of 15 prohibited and restricted veterinary drug residues in animal derived food by high performance liquid chromatography-tandem mass spectrometry[J]. China Feed,2023(2):97−100.] LI Ning, XIAO Jin, WANG Xuesong, et al. Simultaneous determination of 15 prohibited and restricted veterinary drug residues in animal derived food by high performance liquid chromatography-tandem mass spectrometry[J]. China Feed, 2023(2): 97−100.

[13] 刘青, 梁晓聪, 张巍, 等. 2016—2019年陕西省动物源性食品中甲硝唑和氯霉素残留状况[J]. 卫生研究,2021,50(6):1019−1021,1024. [LIU Qing, LIU Xiaocong, ZHANG Wei, et al. Residues of metronidazole and chloramphenicol in foods of animal origin in Shaanxi province, 2016-2019[J]. Journal of Hygiene Research,2021,50(6):1019−1021,1024.] LIU Qing, LIU Xiaocong, ZHANG Wei, et al. Residues of metronidazole and chloramphenicol in foods of animal origin in Shaanxi province, 2016-2019[J]. Journal of Hygiene Research, 2021, 50(6): 1019−1021,1024.

[14] 张飞, 王远, 马小宁, 等. 超高效液相色谱-串联质谱法检测卤肉中36种兽药残留[J]. 食品工业科技,2023,44(13):343−351. [ZHANG Fei, WANG Yuan, MA Xiaoning, et al. Determination of 36 veterinary drug residues in cooked meat by ultra performance liquid chromatography-tandem mass spectrometry[J]. Science and Technology of Food Industry,2023,44(13):343−351.] ZHANG Fei, WANG Yuan, MA Xiaoning, et al. Determination of 36 veterinary drug residues in cooked meat by ultra performance liquid chromatography-tandem mass spectrometry[J]. Science and Technology of Food Industry, 2023, 44(13): 343−351.

[15] YOSHIKAWA S, NAGANO C, KANDA M, et al. Simultaneous determination of multi-class veterinary drugs in chicken processed foods and muscle using solid-supported liquid extraction clean-up[J]. Journal of Chromatography B,2017,1057:15−23. doi: 10.1016/j.jchromb.2017.04.041

[16] 杜俊琪, 苟静, 谢碧秀, 等. 加工和储存对动物源食品中兽药残留降解的影响[J]. 食品工业,2023,44(11):190−196. [DU Junqi, GOU Jing, XIE Bixiu, et al. The effects of processing and storage on the degradation of veterinary drug residues in animal-derived foods[J]. Food Industry,2023,44(11):190−196.] doi: 10.3969/j.issn.1004-471X.spgy202311045 DU Junqi, GOU Jing, XIE Bixiu, et al. The effects of processing and storage on the degradation of veterinary drug residues in animal-derived foods[J]. Food Industry, 2023, 44(11): 190−196. doi: 10.3969/j.issn.1004-471X.spgy202311045

[17] 吴清玉. 我国土壤环境监测及修复技术现状[J]. 中国科技信息,2021(2):115−116. [WU Qingyu. Current status of soil environmental monitoring and remediation technology in China[J]. China Science and Technology Information,2021(2):115−116.] WU Qingyu. Current status of soil environmental monitoring and remediation technology in China[J]. China Science and Technology Information, 2021(2): 115−116.

[18] 张琳, 苏玲玉, 王文娟. 2017—2019年甘南地区市售畜禽肉制品重金属监测分析[J]. 甘肃畜牧兽医,2021,51(5):70−72,75. [ZHANG Lin, SU Lingyu, WANG Wenjuan. Monitoring analysis of heavy metals in commercially available livestock and poultry meat products in Gannan 2017-2019[J]. Gansu Animal Husbandry and Veterinary,2021,51(5):70−72,75.] doi: 10.3969/j.issn.1006-799X.2021.05.021 ZHANG Lin, SU Lingyu, WANG Wenjuan. Monitoring analysis of heavy metals in commercially available livestock and poultry meat products in Gannan 2017-2019[J]. Gansu Animal Husbandry and Veterinary, 2021, 51(5): 70−72,75. doi: 10.3969/j.issn.1006-799X.2021.05.021

[19] 商慧敏, 陆秀军, 蒲云霞. 2019—2021年内蒙古地区畜禽肉及内脏中5种重金属污染调查[J]. 卫生研究,2023,52(1):148−151. [SHANG Huimin, LU Xiujun, PU Yunxia. Survey of five heavy metal contaminations in livestock and poultry meat and offal in Inner Mongolia, 2019-2021[J]. Journal of Hygiene Reserch,2023,52(1):148−151.] SHANG Huimin, LU Xiujun, PU Yunxia. Survey of five heavy metal contaminations in livestock and poultry meat and offal in Inner Mongolia, 2019-2021[J]. Journal of Hygiene Reserch, 2023, 52(1): 148−151.

[20] 王雅洁, 杨冰, 何锦林, 等. 我国各地区畜禽肉中重金属污染物水平的安全评价及分布特征[J]. 食品安全质量检测学报,2018,9(9):2258−2266. [WANG Yajie, YANG Bing, HE Jinlin, et al. Safety assessment and distribution characteristics of heavy metal pollutants in livestock and poultry meats in different regions of China[J]. Journal of Food Safety and Quality,2018,9(9):2258−2266.] doi: 10.3969/j.issn.2095-0381.2018.09.047 WANG Yajie, YANG Bing, HE Jinlin, et al. Safety assessment and distribution characteristics of heavy metal pollutants in livestock and poultry meats in different regions of China[J]. Journal of Food Safety and Quality, 2018, 9(9): 2258−2266. doi: 10.3969/j.issn.2095-0381.2018.09.047

[21] 杨丽, 付鹏钰, 李杉, 等. 河南省市售畜禽肉与水产品中重金属污染状况调查[J]. 中国卫生产业,2019,16(32):3−7. [YANG Li, FU Pengyu, LI Shan, et al. Investigation on heavy metal pollution status of livestock and poultry meat and aquatic products in Henan province[J]. China Health Industry,2019,16(32):3−7.] YANG Li, FU Pengyu, LI Shan, et al. Investigation on heavy metal pollution status of livestock and poultry meat and aquatic products in Henan province[J]. China Health Industry, 2019, 16(32): 3−7.

[22] 欧爱芬, 张挺, 梁兰兰, 等. 电感耦合等离子体质谱(ICP-MS)测定畜禽肉中9种重金属元素含量[J]. 食品工业科技,2021,42(7):282−288. [OU Aifen, ZHANG Ting, LIANG Lanlan, et al. Determination of nine metal elements in livestock and poultry meat by ICP-MS[J]. Science and Technology of Food Industry,2021,42(7):282−288.] OU Aifen, ZHANG Ting, LIANG Lanlan, et al. Determination of nine metal elements in livestock and poultry meat by ICP-MS[J]. Science and Technology of Food Industry, 2021, 42(7): 282−288.

[23] 段玉林, 陈栎岩, 宁方尧, 等. 肉制品中重金属及兽药残留现状研究[J]. 食品安全质量检测学报,2021,12(8):3008−3015. [DUAN Yulin, CHEN Liyan, NING Fangao, et al. Study on the residual pollution of heavy metals and veterinary drugs in meat products[J]. Journal of Food Safety & Quality,2021,12(8):3008−3015.] DUAN Yulin, CHEN Liyan, NING Fangao, et al. Study on the residual pollution of heavy metals and veterinary drugs in meat products[J]. Journal of Food Safety & Quality, 2021, 12(8): 3008−3015.

[24] KHAN I A, KHAN A, ZOU Y, et al. Heterocyclic amines in cooked meat products, shortcomings during evaluation, factors influencing formation, risk assessment and mitigation strategies[J]. Meat Sci,2022,184:108693. doi: 10.1016/j.meatsci.2021.108693

[25] 徐燕, 梁俭, 马吉娜, 等. 烹调方式对不同肉及其制品中杂环胺的影响概述[J]. 食品安全质量检测学报,2021,12(8):2974−2983. [XU Yan, LIANG Jian, MA Jina, et al. Research progress on the influence of cooking methods on heterocyclic aromatic amines in different meat and meat products[J]. Journal of Food Safety & Quality,2021,12(8):2974−2983.] XU Yan, LIANG Jian, MA Jina, et al. Research progress on the influence of cooking methods on heterocyclic aromatic amines in different meat and meat products[J]. Journal of Food Safety & Quality, 2021, 12(8): 2974−2983.

[26] PLEVA D, KATALIN L, MONORI K D, et al. Heterocyclic amine formation in grilled chicken depending on body parts and treatment conditions[J]. Molecules,2020,25(7):1547. doi: 10.3390/molecules25071547

[27] ZHOU Yajun, ZHANG Yuxia, DONG Xuewen. Determination of heterocyclic amines in braised sauce beef and the effects of different cooking conditions on the formation of heterocyclic amines[J]. Journal of the Science of Food and Agriculture,2022,102(2):617−627. doi: 10.1002/jsfa.11391

[28] FAN Heyu, HU Huiyu, LI Chang, et al. Effects of cooking factors on the formation of heterocyclic aromatic amines in fried beef patties[J]. Journal of Food Processing and Preservation,2022(2):46.

[29] SHA Lei, LIU Susu. Effect of tea polyphenols on the inhibition of heterocyclic aromatic amines in grilled mutton patties[J]. Journal of Food Processing and Preservation,2022,46(10):e16811.

[30] MOTTRAM D S, WEDZICHA B L, DODSON A T. Acrylamide is formed in the Maillard reaction[J]. Nature,2002,419(6906):448−449. doi: 10.1038/419448a

[31] TAEYMANS D, WOOD J, ASHBY P, et al. A review of acrylamide:An industry perspective on research, analysis, formation, and control[J]. Critical Reviews in Food Science and Nutrition,2004,44(5):323−347. doi: 10.1080/10408690490478082

[32] LIU Yanbing, WANG Pengpu, CHEN Fang, et al. Role of plant polyphenols in acrylamide formation and elimination[J]. Food Chemistry, 2015, 186.

[33] MAAN A A, ANJUM M A, KASHIF M, et al. Acrylamide formation and different mitigation strategies during food processing-A review[J]. Food Rev Int,2020,36(2):157.

[34] 周睿, 杨海昕, 曹云, 等. 双固相萃取柱净化-超高效液相色谱法测定热加工食品中的丙烯酰胺[J]. 现代预防医学,2022,49(13):2447−2450. [ZHOU Rui, YANG Haixin, CAO Yun, et al. Determination of acrylamide in hot processed foods by double solid phase extraction columns purification combined with ultra-high performance liquid chromatography[J]. Modern Preventive Medicine,2022,49(13):2447−2450.] ZHOU Rui, YANG Haixin, CAO Yun, et al. Determination of acrylamide in hot processed foods by double solid phase extraction columns purification combined with ultra-high performance liquid chromatography[J]. Modern Preventive Medicine, 2022, 49(13): 2447−2450.

[35] TREVISAN A J B, LIMA D D A, SAMPAIO G R, et al. Influence of home cooking conditions on Maillard reaction products in beef[J]. Food Chemistry,2016,196:161−169. doi: 10.1016/j.foodchem.2015.09.008

[36] 刘玲玲. 红烧肉加工过程中营养成分变化及丙烯酰胺抑制研究[D]. 南昌:南昌大学, 2016. [LIU Lingling. Study on the changes of nutrients during cooking of Braised pork inbrown sauce and suppression method of acrylamide[D]. Nanchang:Nanchang University, 2016.] LIU Lingling. Study on the changes of nutrients during cooking of Braised pork inbrown sauce and suppression method of acrylamide[D]. Nanchang: Nanchang University, 2016.

[37] PEIVASTEHROUDSARI L, KARAMI M, BARZEGARBAFROUEI R, et al. Toxicity, metabolism, and mitigation strategies of acrylamide:A comprehensive review[J]. International Journal of Environmental Health Research,2024,34(1):1−29. doi: 10.1080/09603123.2022.2123907

[38] RAJESH T P, BASHEER V A, PACKIRISAMY A S B, et al. Effective Inhibition of enzymatic browning and carcinogenic acrylamide in fried food by polyphenols[J]. Topics in Catalysis,2024,67(1):300−312.

[39] PANG Y, CHEN J, YANG J, et al. Protective effect and mechanism of Lycium ruthenicum polyphenols against acrylamide-induced neurotoxicity[J]. Food & Function,2023,14(10):4552−4568.

[40] SHAKIL M H, TRISHA A T, RAHMAN M, et al. Nitrites in cured meats, health risk issues, alternatives to nitrites:A review[J]. Foods,2022,11(21):3355. doi: 10.3390/foods11213355

[41] 杨慧娟, 谭芦兰, 唐宏刚, 等. 肉制品中亚硝胺控制的研究进展[J]. 食品科学技术学报,2019,37(5):72−76. [YANG Huijuan, TAN Lulan, TANG Honggang, et al. Review on progress of control of nitrosamines in meat products[J]. Journal of Food Science and Technology,2019,37(5):72−76.] doi: 10.3969/j.issn.2095-6002.2019.05.009 YANG Huijuan, TAN Lulan, TANG Honggang, et al. Review on progress of control of nitrosamines in meat products[J]. Journal of Food Science and Technology, 2019, 37(5): 72−76. doi: 10.3969/j.issn.2095-6002.2019.05.009

[42] 蔡鲁峰, 李娜, 杜莎, 等. N-亚硝基化合物的危害及其在体内外合成和抑制的研究进展[J]. 食品科学,2016,37(5):271−277. [CAI Lufeng, LI Na, DU Sha, et al. Progress in hazards, synthesis and inhibition of N-nitroso compounds in vitro and in vivo[J]. Food Science,2016,37(5):271−277.] CAI Lufeng, LI Na, DU Sha, et al. Progress in hazards, synthesis and inhibition of N-nitroso compounds in vitro and in vivo[J]. Food Science, 2016, 37(5): 271−277.

[43] 江黎雯, 薛超轶, 何志勇, 等. 肉制品中3类有害物质的来源与控制方法研究进展[J]. 肉类研究,2020,34(4):77−87. [JIANG Liwen, XUE Chaoyi, HE Zhiyong, et al. A review of three kinds of hazardous substances in meat products:Sources and control methods[J]. Meat Research,2020,34(4):77−87.] doi: 10.7506/rlyj1001-8123-20200131-028 JIANG Liwen, XUE Chaoyi, HE Zhiyong, et al. A review of three kinds of hazardous substances in meat products: Sources and control methods[J]. Meat Research, 2020, 34(4): 77−87. doi: 10.7506/rlyj1001-8123-20200131-028

[44] 轩伟, 付传鹏, 丁文燮. 2014—2018年商丘市散装熟肉食品亚硝酸盐含量分析[J]. 河南医学高等专科学校学报,2022,34(5):575−578. [XUAN Wei, FU Chuanpeng, DING Wenxie. Analysis of nitrite content in bulk cooked meat food in Shangqiu from 2014 to 2018[J]. Journal of Henan Medical College,2022,34(5):575−578.] doi: 10.3969/j.issn.1008-9276.2022.05.013 XUAN Wei, FU Chuanpeng, DING Wenxie. Analysis of nitrite content in bulk cooked meat food in Shangqiu from 2014 to 2018[J]. Journal of Henan Medical College, 2022, 34(5): 575−578. doi: 10.3969/j.issn.1008-9276.2022.05.013

[45] 尤芳芳, 孙亚真, 宁水平, 等. 2018—2019年洛阳市市售熟肉制品中亚硝酸盐含量分析[J]. 食品安全质量检测学报,2021,12(6):2503−2507. [YOU Fangfang, SUN Yazhen, NING Shuiping, et al. Analysis of nitrite content in cooked meat products sold in Luoyang City from 2018 to 2019[J]. Journal of Food Safety and Quality,2021,12(6):2503−2507.] YOU Fangfang, SUN Yazhen, NING Shuiping, et al. Analysis of nitrite content in cooked meat products sold in Luoyang City from 2018 to 2019[J]. Journal of Food Safety and Quality, 2021, 12(6): 2503−2507.

[46] 刘万臣, 刘爱萍, 赵榕, 等. 肉制品加工及贮存过程中亚硝酸盐含量的变化与安全性分析[J]. 食品科学,2010,31(1):113−116. [LIU Wanchen, LIU Aiping, ZHAO Rong, et al. Change and safety assessment of nitrite in meat products during processing and storage[J]. Food Science,2010,31(1):113−116.] LIU Wanchen, LIU Aiping, ZHAO Rong, et al. Change and safety assessment of nitrite in meat products during processing and storage[J]. Food Science, 2010, 31(1): 113−116.

[47] 石如月, 刘洋, 孙杨赢, 等. 发酵剂对鸭肉发酵香肠亚硝酸盐及生物胺的抑制作用[J]. 食品工业科技,2023,44(10):116−122. [SHI Ruyue, LIU Yang, SUN Yangying, et al. Inhibition of starter culture on nitrite and biogenic amines in fermented duck sausage[J]. Science and Technology of Food Industry,2023,44(10):116−122.] SHI Ruyue, LIU Yang, SUN Yangying, et al. Inhibition of starter culture on nitrite and biogenic amines in fermented duck sausage[J]. Science and Technology of Food Industry, 2023, 44(10): 116−122.

[48] 黄苓, 孙震, 吴爱娟, 等. 一种零添加亚硝酸盐腌腊肉的加工工艺[J]. 宁波大学学报(理工版),2019,32(3):21−27. [HUANG Lin, SUN Zhen, WU Aijuan, et al. Optimization of processing technology for no-nitrite-added cured meat[J]. Journal of Ningbo University,2019,32(3):21−27.] doi: 10.3969/j.issn.1001-5132.2019.03.004 HUANG Lin, SUN Zhen, WU Aijuan, et al. Optimization of processing technology for no-nitrite-added cured meat[J]. Journal of Ningbo University, 2019, 32(3): 21−27. doi: 10.3969/j.issn.1001-5132.2019.03.004

[49] 聂文, 屠泽慧, 占剑峰, 等. 食品加工过程中多环芳烃生成机理的研究进展[J]. 食品科学,2018,39(15):269−274. [NIE Wen, TU Zehui, ZHAN Jianfeng, et al. Mechanism of polycyclic aromatic hydrocarbon formation in food processing:A review[J]. Food Science,2018,39(15):269−274.] doi: 10.7506/spkx1002-6630-201815039 NIE Wen, TU Zehui, ZHAN Jianfeng, et al. Mechanism of polycyclic aromatic hydrocarbon formation in food processing: A review[J]. Food Science, 2018, 39(15): 269−274. doi: 10.7506/spkx1002-6630-201815039

[50] ADEYEYE S A O, ASHAOLU T J. Polycyclic aromatic hydrocarbons formation and mitigation in meat and meat products[J]. Polycyclic Aromatic Compounds,2022,42(6):3401−3411. doi: 10.1080/10406638.2020.1866039

[51] ONOPIUK A, KOLODZIEJCZAK K, MARCINKOWSKA-LESIAK M, et al. Determination of polycyclic aromatic hydrocarbons using different extraction methods and HPLC-FLD detection in smoked and grilled meat products[J]. Food Chemistry,2022,373:131506. doi: 10.1016/j.foodchem.2021.131506

[52] 齐颖. 油炸肉制品加工过程中多环芳烃的形成及控制研究[D]. 天津:天津科技大学, 2015. [QI Ying. Study of formation and inhibition of polycyclic aromatic hydrocarbons during the prosess of frying meat product[D]. Tianjin:Tianjin University of Science and Technology, 2015.] QI Ying. Study of formation and inhibition of polycyclic aromatic hydrocarbons during the prosess of frying meat product[D]. Tianjin: Tianjin University of Science and Technology, 2015.

[53] 魏健, 王莉, 刘飞, 等. 变温烤制对新疆馕坑烤肉色泽、嫩度、杂环胺及多环芳烃含量的影响[J]. 食品科学,2023,44(21):121−130. [WEI Jian, WANG Li, LIU Fei, et al. Effect of variable temperature roasting on the colour, tenderness, content of heterocyclic amines and polycyclic aromatic hydrocarbons in Xinjiang roasted mutton by tannur[J]. Food Science,2023,44(21):121−130.] doi: 10.7506/spkx1002-6630-20221007-050 WEI Jian, WANG Li, LIU Fei, et al. Effect of variable temperature roasting on the colour, tenderness, content of heterocyclic amines and polycyclic aromatic hydrocarbons in Xinjiang roasted mutton by tannur[J]. Food Science, 2023, 44(21): 121−130. doi: 10.7506/spkx1002-6630-20221007-050

[54] 张智宏, 杨逸凡, 韩新阳, 等. 预制菜包装技术的研究进展[J]. 包装工程,2023,44(9):1−9. [ZHANG Zhihong, YANG Yifan, HAN Xinyang, et al. Research progress on packaging technology of prepared food[J]. Packaging Engineering,2023,44(9):1−9.] ZHANG Zhihong, YANG Yifan, HAN Xinyang, et al. Research progress on packaging technology of prepared food[J]. Packaging Engineering, 2023, 44(9): 1−9.

[55] 胡长鹰, 王志伟, 李立, 等. 预制菜包装材料及其品质安全保障[C]// 中国食品科学技术学会. 中国食品科学技术学会第十九届年会论文摘要集, 2022:423−424. [HU Changying, WANG Zhiwei, LI Li, et al. Effect of nanocrystalline cellulose synergistic calcium chloride on film-forming properties of pea protein[C]// Abstracts of the 19th Annual of CIFST, 2022:423−424.] HU Changying, WANG Zhiwei, LI Li, et al. Effect of nanocrystalline cellulose synergistic calcium chloride on film-forming properties of pea protein[C]// Abstracts of the 19th Annual of CIFST, 2022: 423−424.

[56] ALAMRI M S, QASEM AKRAM A A, MOHAMED A A, et al. Food packaging's materials:A food safety perspective[J]. Saudi Journal of Biological Sciences,2021,28(8):4490−4499. doi: 10.1016/j.sjbs.2021.04.047

[57] 陈家凤, 吴巨贤, 程学勋, 等. 现代保鲜技术在畜禽肉类预制菜中的应用[J]. 现代食品,2023,29(11):67−69. [CHEN Jiafeng, WU Juxian, CHENG Xuexun, et al. Application of modern preservation technology in prefabricated foods of livestock and poultry meat[J]. Food Science and Technology,2023,29(11):67−69.] CHEN Jiafeng, WU Juxian, CHENG Xuexun, et al. Application of modern preservation technology in prefabricated foods of livestock and poultry meat[J]. Food Science and Technology, 2023, 29(11): 67−69.

[58] 付清, 王赵劼, 柯建杨, 等. 外卖餐具中16种合成酚类抗氧化剂的含量及迁移分析[J]. 食品安全质量检测学报,2024,15(6):297−303. [FU Qing, WANG Zhaojie, KE Jianyang, et al. Content and migration analysis of 16 kinds of synthetic phenolic antioxidants in takeaway tableware[J]. Journal of Food Safety and Quality,2024,15(6):297−303.] FU Qing, WANG Zhaojie, KE Jianyang, et al. Content and migration analysis of 16 kinds of synthetic phenolic antioxidants in takeaway tableware[J]. Journal of Food Safety and Quality, 2024, 15(6): 297−303.

[59] ABDOLLAHZADEH E, NEMATOLLAHI A, HOSSEINI H. Composition of antimicrobial edible films and methods for assessing their antimicrobial activity:A review[J]. Trends in Food Science & Technology,2021,110:291−303.

[60] YIN W Q, QIU C, JI H Y, et al. Recent advances in biomolecule-based films and coatings for active and smart food packaging applications[J]. Food Bioscience, 2023:102378.

[61] JAFARZADEH S, FOROUGH M, AMJADI S, et al. Plant protein-based nanocomposite films:A review on the used nanomaterials, characteristics, and food packaging applications[J]. Critical Reviews in Food Science and Nutrition,2023,63(29):9667−9693. doi: 10.1080/10408398.2022.2070721

[62] 张园园, 朱瑶迪, 李苗云, 等. 胀袋红烧肉和酱料包中产气微生物的分离与鉴定[J]. 现代食品科技,2022,38(7):107−112,26. [ZHANG Yuanyuan, ZHU Yaodi, LI Miaoyun, et al. Isolation and identification of gas-producing microorganisms from bagging red braised pork and sauce packs[J]. Modern Food Science and Technology,2022,38(7):107−112,26.] ZHANG Yuanyuan, ZHU Yaodi, LI Miaoyun, et al. Isolation and identification of gas-producing microorganisms from bagging red braised pork and sauce packs[J]. Modern Food Science and Technology, 2022, 38(7): 107−112,26.

[63] 李慧, 卢玉, 钟鸣, 等. 土豆烧牛肉方便菜肴胀袋微生物分离鉴定及产气特性研究[J]. 粮油食品科技,2020,28(4):36−42. [LI Hui, LU Yu, ZHONG Ming, et al. Isolation, identification and gas generation of spoilage microorganisms from swollen braised brisket with potato[J]. Science And Technology of Cereals, Oils and Foods,2020,28(4):36−42.] LI Hui, LU Yu, ZHONG Ming, et al. Isolation, identification and gas generation of spoilage microorganisms from swollen braised brisket with potato[J]. Science And Technology of Cereals, Oils and Foods, 2020, 28(4): 36−42.

[64] 李新, 汪兰, 吴文锦, 等. 熟制鸭肉超高压杀菌技术初探[J]. 保鲜与加工,2018,18(2):50−54,60. [LI Xin, WANG Lan, WU Wenjin, et al. Exploration of ultra-high pressure sterilization on cooked duck meat[J]. Storage and Process,2018,18(2):50−54, 60.] doi: 10.3969/j.issn.1009-6221.2018.02.009 LI Xin, WANG Lan, WU Wenjin, et al. Exploration of ultra-high pressure sterilization on cooked duck meat[J]. Storage and Process, 2018, 18(2): 50−54, 60. doi: 10.3969/j.issn.1009-6221.2018.02.009

[65] 方春玉, 吕枫, 王卫, 等. 四川特色肉类菜肴小煎鸡工业化加工工艺研究[J]. 农产品加工,2020(16):29−32. [FANG Chunyu, LÜ Feng, WANG Wei, et al. Research on the industrial production process of the little fried chicken of special dishes in Sichuan[J]. Farm Products Processing,2020(16):29−32.] FANG Chunyu, LÜ Feng, WANG Wei, et al. Research on the industrial production process of the little fried chicken of special dishes in Sichuan[J]. Farm Products Processing, 2020(16): 29−32.

[66] 黄本婷. 川菜家常菜肴回锅肉工业化加工技术研究[D]. 成都:成都大学, 2020. [HUANG Benting. Study on the industrialized processing technology of Sichuan Hui Guo-rou[D]. Chengdu:Chengdu University, 2020.] HUANG Benting. Study on the industrialized processing technology of Sichuan Hui Guo-rou[D]. Chengdu: Chengdu University, 2020.

[67] 王思涵. 包装材料、贮藏温度和灭菌处理对三种中式预制菜肴品质的影响[D]. 延吉:延边大学, 2022. [WANG Sihan. Packaging materials, storage temperature and sterilization treatment influence of three Chinese prefabricated food on their quality[D]. Yanji:Yanbian University, 2022.] WANG Sihan. Packaging materials, storage temperature and sterilization treatment influence of three Chinese prefabricated food on their quality[D]. Yanji: Yanbian University, 2022.

[68] 黄欣悦. 萝卜炖牛腩预制菜加工工艺研究[D]. 武汉:华中农业大学, 2022. [HUANG Xinyue. Research on the processing technology of prepared food stewed brisket with radish[D]. Wuhan:Huazhong Agricultural University, 2022.] HUANG Xinyue. Research on the processing technology of prepared food stewed brisket with radish[D]. Wuhan: Huazhong Agricultural University, 2022.

[69] 彭文怡, 吕欣东. 预熟制调理食品急速冷冻前后品质变化研究[J]. 粮食与油脂,2023,36(3):95−97,103. [PENG Wenyi, LÜ Xindong. Study on the quality change of pre-cooked prepared food before and after rapid freezing[J]. Cereals & Oils,2023,36(3):95−97,103.] doi: 10.3969/j.issn.1008-9578.2023.03.022 PENG Wenyi, LÜ Xindong. Study on the quality change of pre-cooked prepared food before and after rapid freezing[J]. Cereals & Oils, 2023, 36(3): 95−97,103. doi: 10.3969/j.issn.1008-9578.2023.03.022

[70] 黄卉, 徐依婷, 李来好, 等. 可微波冷冻预油炸食品的研究进展[J]. 中国调味品,2023,48(4):216−220. [HUANG Hui, XU Yiting, LI Laihao, et al. Research progress of microwaveable frozen pre-fried foods[J]. China Condiment,2023,48(4):216−220.] doi: 10.3969/j.issn.1000-9973.2023.04.038 HUANG Hui, XU Yiting, LI Laihao, et al. Research progress of microwaveable frozen pre-fried foods[J]. China Condiment, 2023, 48(4): 216−220. doi: 10.3969/j.issn.1000-9973.2023.04.038

[71] WILLS K M , MITACEK R M, MAFI G G, et al. Improving the lean muscle color of dark cutting beef by aging, antioxidant-enhancement, and modified atmospheric packaging[J]. Journal of Animal Science, 2017, 95(12):5378−5387.

[72] 张凯华, 臧明伍, 张哲奇, 等. 微波复热时间对预制猪肉饼过熟味、脂肪氧化和水分分布特性的影响[J]. 食品科学,2020,41(9):50−56. [ZHANG Kaihua, ZANG Mingwu, ZHANG Zheqi, et al. Effect of microwave reheating time on warmed-over flavor, lipid oxidation and water distribution in precooked pork patties[J]. Food Science,2020,41(9):50−56.] ZHANG Kaihua, ZANG Mingwu, ZHANG Zheqi, et al. Effect of microwave reheating time on warmed-over flavor, lipid oxidation and water distribution in precooked pork patties[J]. Food Science, 2020, 41(9): 50−56.

[73] 周惠健. 红烧老鹅加工工艺优化与贮藏品质的研究[D]. 扬州:扬州大学, 2019. [ZHOU Huijian. Study on the optimization of processing and storage quality of red-roasted old goose[D]. Yangzhou:Yangzhou University, 2019.] ZHOU Huijian. Study on the optimization of processing and storage quality of red-roasted old goose[D]. Yangzhou: Yangzhou University, 2019.

[74] 张凯华, 臧明伍, 张哲奇, 等. 不同复热方式对猪耳朵制品挥发性风味和脂肪氧化的影响[J]. 食品科学,2018,39(14):242−248. [ZHANG Kaihua, ZANG Mingwu, ZHANG Zheqi, et al. Effect of reheating methods on volatile flavor constituents and lipid oxidation in cooked pig ear[J]. Food Science,2018,39(14):242−248.] doi: 10.7506/spkx1002-6630-201814036 ZHANG Kaihua, ZANG Mingwu, ZHANG Zheqi, et al. Effect of reheating methods on volatile flavor constituents and lipid oxidation in cooked pig ear[J]. Food Science, 2018, 39(14): 242−248. doi: 10.7506/spkx1002-6630-201814036

[75] 董芝杰. 不同复热方式对猪肉丸品质的影响[J]. 美食研究,2022,39(4):66−70. [DONG Zhijie. Effects of different reheating methods on the quality characteristics of pork meatballs[J]. Journal of Researches on Dietetic Science and Culture,2022,39(4):66−70.] DONG Zhijie. Effects of different reheating methods on the quality characteristics of pork meatballs[J]. Journal of Researches on Dietetic Science and Culture, 2022, 39(4): 66−70.

[76] 陈乐. 西红柿炖牛腩菜肴工业化加工工艺研究[D]. 银川:宁夏大学, 2022. [CHEN Le. Study on industrialized processing technology of Stewed Beef Brisket with tomato[D]. Yinchuan:Ningxia University, 2022.] CHEN Le. Study on industrialized processing technology of Stewed Beef Brisket with tomato[D]. Yinchuan: Ningxia University, 2022.

[77] 昝博文. 预制调理工艺对猪肉品质特性的影响研究[D]. 成都:成都大学, 2023. [ZAN Bowen. Study on the effects of prepared technology on pork quality[D]. Chengdu:Chengdu University, 2023.] ZAN Bowen. Study on the effects of prepared technology on pork quality[D]. Chengdu: Chengdu University, 2023.

下载:

下载:

下载:

下载: