Effects of Microwave Treatment on the Structure and Physicochemical Properties of Three Kinds of Starches

-

摘要: 为探究微波处理对绿豆淀粉、豌豆淀粉、籼米淀粉结构特性和理化性质的影响,以这3种淀粉为原料,探究微波处理对3种淀粉的直链淀粉含量、颗粒形貌、偏光特性、结晶结构、短程有序性、热特性、糊化特性以及凝沉性的影响。结果表明,微波处理后,绿豆淀粉、豌豆淀粉、籼米淀粉的直链淀粉分别由原来的36.78%、40.29%、15.96%提高至45.49%、44.17%、27.78%。经微波处理后,3种淀粉的颗粒表面均有不同程度的裂痕和破损,且偏光十字半数以上消失。微波处理后的绿豆淀粉、豌豆淀粉、籼米淀粉的晶型和官能团未发生改变,但淀粉的相对结晶度分别降低了7.03%、4.94%、5.32%,而且微波处理后3种淀粉的峰值黏度、谷值黏度、回生值、糊化焓值均显著降低(P<0.05)。微波后的绿豆淀粉和豌豆淀粉凝沉速度比籼米淀粉更快且稳定。以上结果表明,微波处理对3种淀粉的颗粒结构和理化性质均有显著影响。Abstract: To investigate the effects of microwave treatment on the structural characteristics and physicochemical properties of mung bean starch, pea starch and indica starch, three kinds of starch before and after microwave treatment were used as raw materials to explore the effects of microwave treatment on amylose content, particle morphology, polarization characteristics, crystallization structure, short-range order, thermal properties, gelatinization properties and retrogradation of three kinds of starch. The results showed that after microwave treatment, the amylose of mung bean starch, pea starch and indica starch increased from 36.78%, 40.29%, 15.96% to 45.49%, 44.17%, 27.78%, respectively. After microwave treatment, the granules of the three kinds of starch showed different degrees of cracks and damage, and more than half of the polarized cross disappeared. The crystal form and functional groups of mung bean starch, pea starch and indica starch after microwave treatment did not change, but the relative crystallinity of starch decreased by 7.03%, 4.94% and 5.32%, respectively. After microwave treatment, the peak viscosity, valley viscosity, retrogradation value and gelatinization enthalpy of the three kinds of starch decreased significantly (P<0.05). The retrogradation rate of mung bean starch and pea starch after microwave treatment was faster and more stable than that of indica starch. The above results showed that microwave treatment had a significant effect on the particle structure and physicochemical properties of the three starches.

-

淀粉广泛存在于自然界中,主要以碳水化合物的形式储存于各种植物根茎和果实中,是人类膳食能量的主要来源[1],同时,淀粉作为一种重要的食品原料与资源,被应用于各行业中[2]。淀粉是以α-D吡喃葡萄糖为基本单位构成的,其中又可分为直链淀粉和支链淀粉两种,直链淀粉是以1,4-糖苷键连接而成的聚合物,而支链淀粉是以1,4-糖苷键和1,6-糖苷键连接而成的聚合物[3]。

淀粉来源不同,其颗粒形态、粒径大小、有序结构及理化性质上存在差异[4]。目前,研究人员对于玉米淀粉、高粱淀粉、马铃薯淀粉研究较多,而对豆类淀粉和米淀粉研究较少,因此,本试验选取绿豆淀粉、豌豆淀粉、籼米淀粉为原料。绿豆淀粉颗粒主呈圆球、椭球和肾形,粒度在3~35 μm,直链淀粉含量约在40%左右[5−6]。豌豆淀粉颗粒主呈椭圆和球形,粒度范围在12~33 μm,以大颗粒为主,直链淀粉含量为35%~65%[7]。两种豆类淀粉均有较高的直链淀粉含量,因此具有胶凝能力好、成膜性强等特性[6,8]。籼米淀粉颗粒呈不规则多边形,粒度在2~8 μm,以小颗粒为主,直链淀粉含量为15%~26%[9−10]。籼米淀粉的直链淀粉含量较低,因此具有吸水性强、不易老化等特性[11]。

淀粉与食品加工密切相关,但天然淀粉依旧有很多不足,如溶解性差、结构不稳定等缺点使其在食品加工行业受到了极大的限制。因此,国内外学者探寻一些技术手段来改善淀粉的功能特性。当前,常用的改性手段有物理、化学、酶法以及复合改性[12]。微波是一种常见的物理改性手段,具有时短效高、节能卫生等特点[13]。李世杰等[14]研究发现,微波能使一部分支链淀粉断裂,形成短直链淀粉,从而提高淀粉的直链淀粉含量。Oyeyinka等[15]研究发现,微波处理会破坏淀粉的晶体结构,使结晶度下降,最终导致淀粉的糊化温度升高。武云娇等[16]研究发现,微波处理会破坏有序结晶结构,导致偏光十字的消失。Anderson等[17]、Zhong等[18]发现微波处理会使淀粉的糊化温度升高,糊化焓值降低。林国荣等[19]研究表明,微波处理会使淀粉的黏度和回生值升高,并提高了其老化程度。唐小闲等[20]研究表明微波处理会使马蹄淀粉更易凝沉。以上研究说明微波处理能够改变淀粉的结构和性质,同时也解决了微波是如何影响淀粉某一结构和特性等问题,但对于微波所引起淀粉结构和理化性质变化的具体原因的探究尚有不足。因此,试验以绿豆淀粉、豌豆淀粉、籼米淀粉为原料,采用微波手段进行改性,探究微波处理引起3种淀粉结构及理化性质变化的原理,以期提高淀粉的适用并为淀粉的改性及应用提供参考。

1. 材料与方法

1.1 材料与仪器

绿豆淀粉、豌豆淀粉 无锡圣伦特国际贸易有限公司;籼米淀粉 无锡金农生物科技有限公司。

M1-L213B微波炉 广东美的厨房电器制造有限公司;TGL-16M高速台式冷冻离心机 湖南湘仪实验室仪器开发有限公司;D8 ADVANCE X射线衍射仪 德国布鲁克公司;SU8020 冷场发射电镜 日本日立有限公司;TENSOR Ⅱ型红外光谱仪 德国Bruker公司;NP-800PRF偏光显微镜 日本奥林巴斯公司;DSC 25 美国TA;RVA4500型快速黏度分析仪 瑞典波通仪器有限公司。

1.2 实验方法

1.2.1 淀粉基本成分的测定

水分含量测定参照GB 5009.3-2016《食品中水分测定》;蛋白质含量测定参照GB 5009.5-2016《食品中蛋白质的测定》;脂肪含量测定参照GB 5009.6-2016《食品中脂肪的测定》;淀粉含量测定参照GB 5009.9-2016《食品中淀粉的测定》;直链淀粉含量、支链淀粉含量采用试剂盒测定,并按照说明书进行操作,公式如下:

直链淀粉含量(mg/g)=[(ΔA+0.0016)/0.08704×V1]/(W×V1/V) 支链淀粉含量(mg/g)=[(ΔA−0.0198)/0.6154×V1]/(W×V1/V) 其中,ΔA为吸光值;V1为测定时所需样品的体积,mL;V为样品提取液总体积,mL;W为样品质量,g。

1.2.2 微波改性淀粉的制备

分别称取适量的绿豆淀粉、豌豆淀粉和籼米淀粉,按1:10的料液比分别在35、35、25 ℃条件下用蒸馏水浸泡1.5、1.5、2 h,后进行离心(8000 r/min,15 min),将离心后的样品置于玻璃皿中铺平,保鲜膜密封并扎孔,常温下放置10 h,此时测得初始的平均干基含水量约为65%,后进行微波处理,在中火条件下(350 W),绿豆淀粉、豌豆淀粉和籼米淀粉的微波时间分别为30、60、30 s,测得微波后样品中心温度为65~70 ℃,后将样品于40 ℃下烘干、粉碎,过筛后得到微波后的淀粉(经前期优化试验得出,3种淀粉在此浸泡和微波条件下直链淀粉达到最高)。

将绿豆淀粉、豌豆淀粉、籼米淀粉分别命名为MBS、PS、IRS,将微波处理后的绿豆淀粉、豌豆淀粉、籼米淀粉分别命名为M-MBS、M-PS、M-IRS。

1.2.3 扫描电子显微镜观察

取少量淀粉并完全烘干,进行镀金处理后,置于扫描电镜样品室内,设置电子枪加速电压为5 kV[21],分别在放大倍数500、5000下观察淀粉形貌的差异。

1.2.4 偏光十字的测定

称取适量淀粉,用蒸馏水将其配成1%的淀粉悬浮液,取一滴置于显微载玻片上,用偏光显微镜在放大20倍条件下观察。

1.2.5 X-射线衍射分析

样品过100目筛后置于X-衍射仪中进行分析,参数设定:管压40 kV,电流100 mA,2θ扫描范围4°~40°,扫描速度2°/min[22−23]。

1.2.6 红外光谱分析

将样品与KBr按1:100混匀研磨、压片,于红外光谱仪上扫描,扫描范围4000~500 cm−1,分辨率4 cm−1,扫描64次[24]。

1.2.7 热特性的测定

将淀粉与蒸馏水按1:3(w/w)制成淀粉乳,密封后在常温下放置12 h平衡水分,采用DSC测定,测定条件:升温速率10 ℃/min,升温范围20~110 ℃。

1.2.8 糊化特性的测定

参考Cao等[25]的方法:将3 g样品与25 mL蒸馏水混匀置于铝盒内,于快速黏度分析仪中进行测定。参数条件:50 ℃保持1 min,以12 ℃/min升至95 ℃,保持2.5 min,以12 ℃/min降至50 ℃,保持3 min;前10 s搅拌速率960 r/min,10 s之后保持160 r/min,并记录样品参数。

1.2.9 凝沉性的测定

称取适量淀粉,用蒸馏水将其配制为1%的淀粉乳,水浴(95 ℃,30 min),取出后将其倒入具塞刻度试管中,冷却,每1 h记录上清液体积,记录12 h[26]。

1.3 数据处理

实验均重复三次,采用SPSS 26、Origin 2019b进行数据分析及图表绘制,显著性分析采用单因素方差分析和t检验法,P<0.05有统计学意义。

2. 结果与分析

2.1 三种淀粉的基本成分

由表1可知,3种淀粉的蛋白含量、脂肪含量很低,但3种淀粉的总淀粉含量均高于94%,说明其纯度较高。3种淀粉的直链淀粉含量由高到低依次为PS、MBS、IRS,有研究指出淀粉中直链淀粉含量的高低是影响淀粉特性的主要因素[27]。

表 1 三种淀粉的基本成分Table 1. Basic components of the three starches样品 水分含量(%) 蛋白含量(%) 脂肪含量(%) 总淀粉含量(%) 直链淀粉含量(%) 支链淀粉含量(%) MBS 11.54±0.17a 1.22±0.04a 0.15±0.01ab 94.98±0.22a 36.78±0.30b 63.02±0.32b PS 11.88±0.24a 1.09±0.11a 0.18±0.03a 94.54±0.31a 40.29±0.13a 59.55±0.17c IRS 9.00±0.21b 0.88±0.05b 0.11±0.03b 94.02±0.13b 15.96±0.17c 84.27±0.25a 注:数据表现为均值±标准方差,同列不同上标小写字母表示差异显著(P<0.05)。 2.2 微波处理对三种淀粉直链淀粉含量的影响

微波处理前后3种淀粉的直链淀粉含量如表2所示,经微波处理后,MBS、PS的直链淀粉含量分别由36.78%、40.29%上升到45.49%和44.17%,这与文献[28]报道的豆类淀粉直链淀粉含量(一般为11.6%~88%)一致[28],籼米淀粉的直链淀粉含量由15.96%上升到27.78%,且微波处理前后3种淀粉的直链淀粉含量存在显著性差异(P<0.05),主要是由于微波处理使淀粉颗粒结构内部聚集了大量的热能,导致淀粉发生部分糊化,随着支链淀粉的膨胀,淀粉颗粒结构变得松动,使支链淀粉的氢键发生断裂,重新形成了大量的短、中直链淀粉[29],因此直链淀粉含量得以提高。

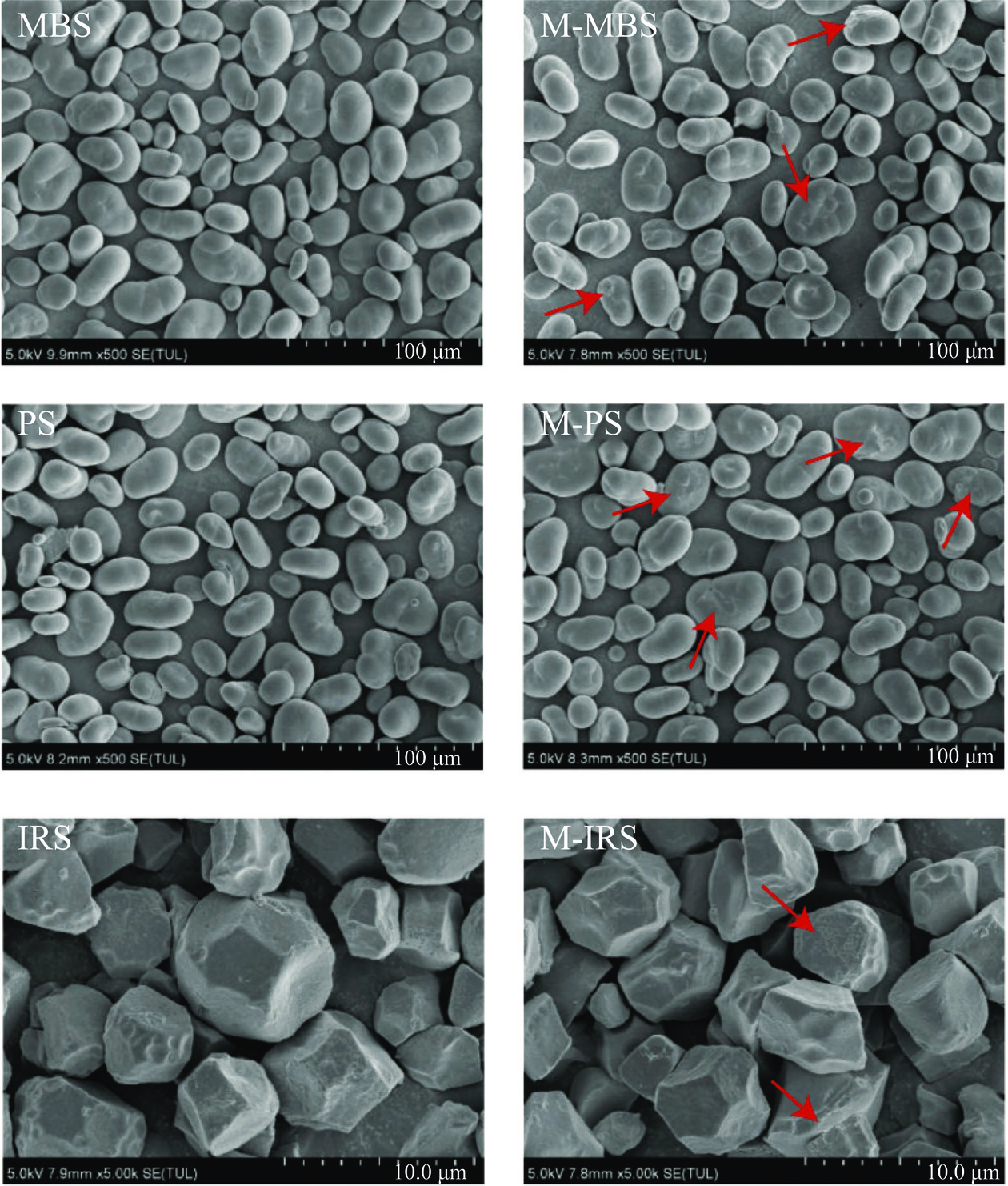

2.3 微波处理对三种淀粉颗粒形貌的影响

由图1可知,MBS、PS形状相似,主要呈椭圆形或球形,且颗粒表面较为光滑。经微波处理后,2种淀粉(M-MBS、M-PS)的形态没有发生明显改变,但有团聚现象,且淀粉颗粒表面均有不同程度的破损。IRS颗粒较小,形状不规则且表面较光滑。微波处理后,IRS的颗粒形态没有明显变化,但有团聚现象且颗粒表面出现破损,这与袁璐等[30]研究结果一致。团聚现象的发生,可能是与微波过程中产生的热能有关,微波处理产生的热能使淀粉发生部分糊化,导致部分直链淀粉的溶出与支链淀粉的溶胀,增加了淀粉颗粒与颗粒之间的黏附力与相互作用力,从而导致淀粉颗粒聚集成团[19]。

2.4 微波处理对三种淀粉偏光十字的影响

偏光十字与淀粉的结晶区相关联,结晶区主要是由支链淀粉组成,若支链淀粉含量发生变化,则会间接导致偏光十字的变化[31]。由图2可知,MBS、PS、IRS的偏光十字清晰且明亮,经微波处理后,3种淀粉(M-MBS、M-PS、M-IRS)的偏光十字半数以上消失,原因是微波后,淀粉内部晶体区域被破坏,结晶区的支链淀粉被部分降解,形成更多的直链淀粉,导致了淀粉偏光十字的模糊和消失[32],此结果与直链淀粉含量测定结果相一致。文献[33−34]的研究也指出,微波处理会破坏淀粉的晶体区域从而导致偏光十字的消失。

2.5 微波处理对三种淀粉晶体结构的影响

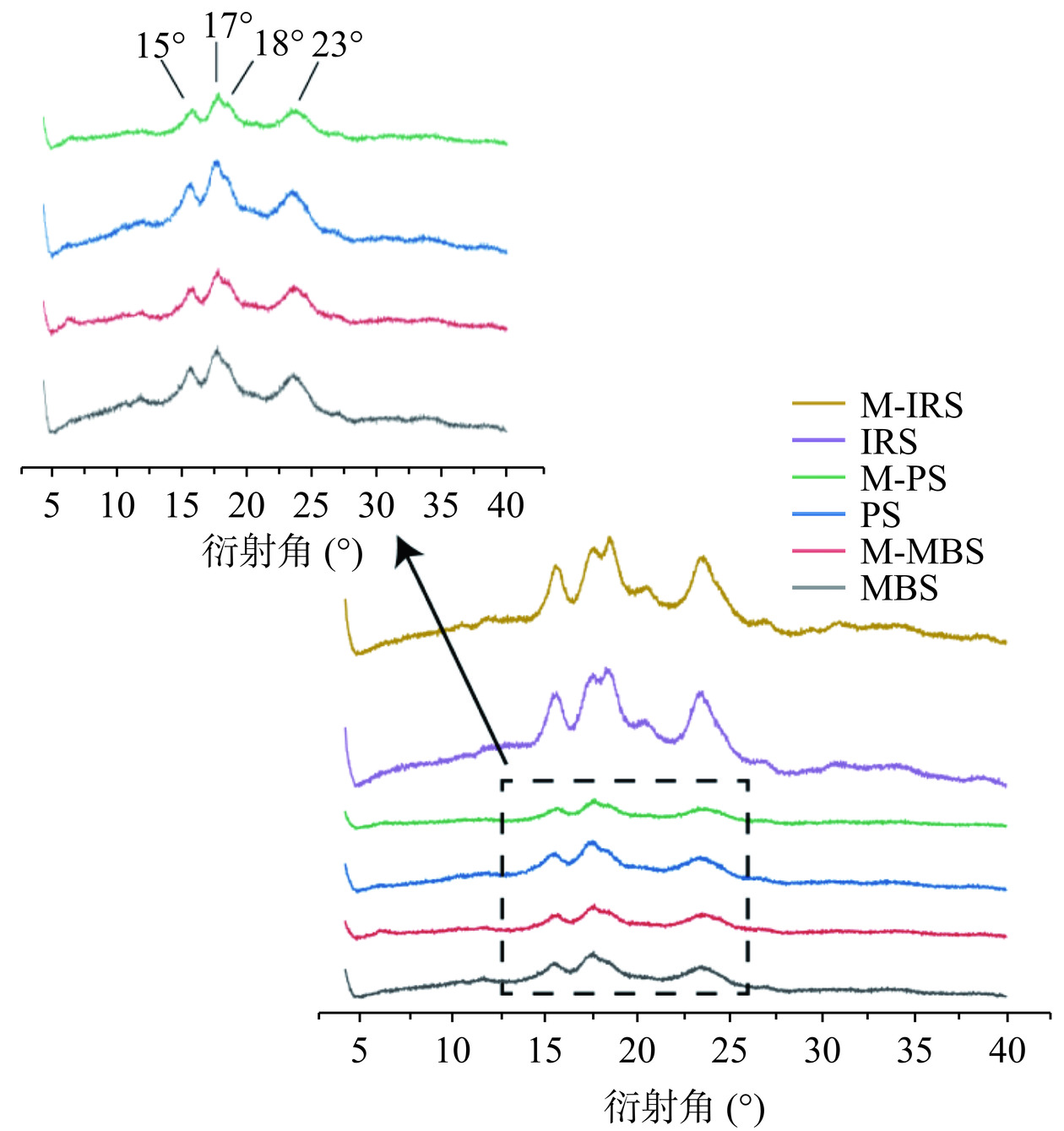

由图3可知,MBS和PS在15°、17°、23°处出现较强的衍射峰,但在18°衍射峰较弱,说明这两种淀粉均为CA-型晶体。经微波处理后的MBS、PS与原淀粉晶型相同,未发生改变。由图还可知,IRS、M-IRS在15°、17°、18°、23°处出现较强的衍射峰,因此IRS、M-IRS均为A型晶体,说明微波处理并没有改变IRS的晶型。以上结果表明,微波处理并未改变3种淀粉的晶型[35]。

由表3可知,微波处理后3种淀粉的相对结晶度均显著降低(P<0.05),微波后的MBS、PS、IRS依次降低了7.03%、4.94%和5.32%,这是因为微波破坏了淀粉的晶体结构,导致支链淀粉向直链淀粉的转变,以及水分子蒸发后导致双螺旋解旋等原因造成的[14],此结果与偏光十字的测定结果相互印证。

表 3 微波处理前后三种淀粉的相对结晶度Table 3. Relative crystallinity of three kinds of starches before and after microwave treatment样品 相对结晶度(%) 微波前 微波后 MBS 34.29±0.25Aa 27.26±0.10Ba PS 31.18±0.34Ab 26.24±0.37Bb IRS 28.29±0.35Ac 22.97±0.52Bc 2.6 微波处理对三种淀粉红外谱图的影响

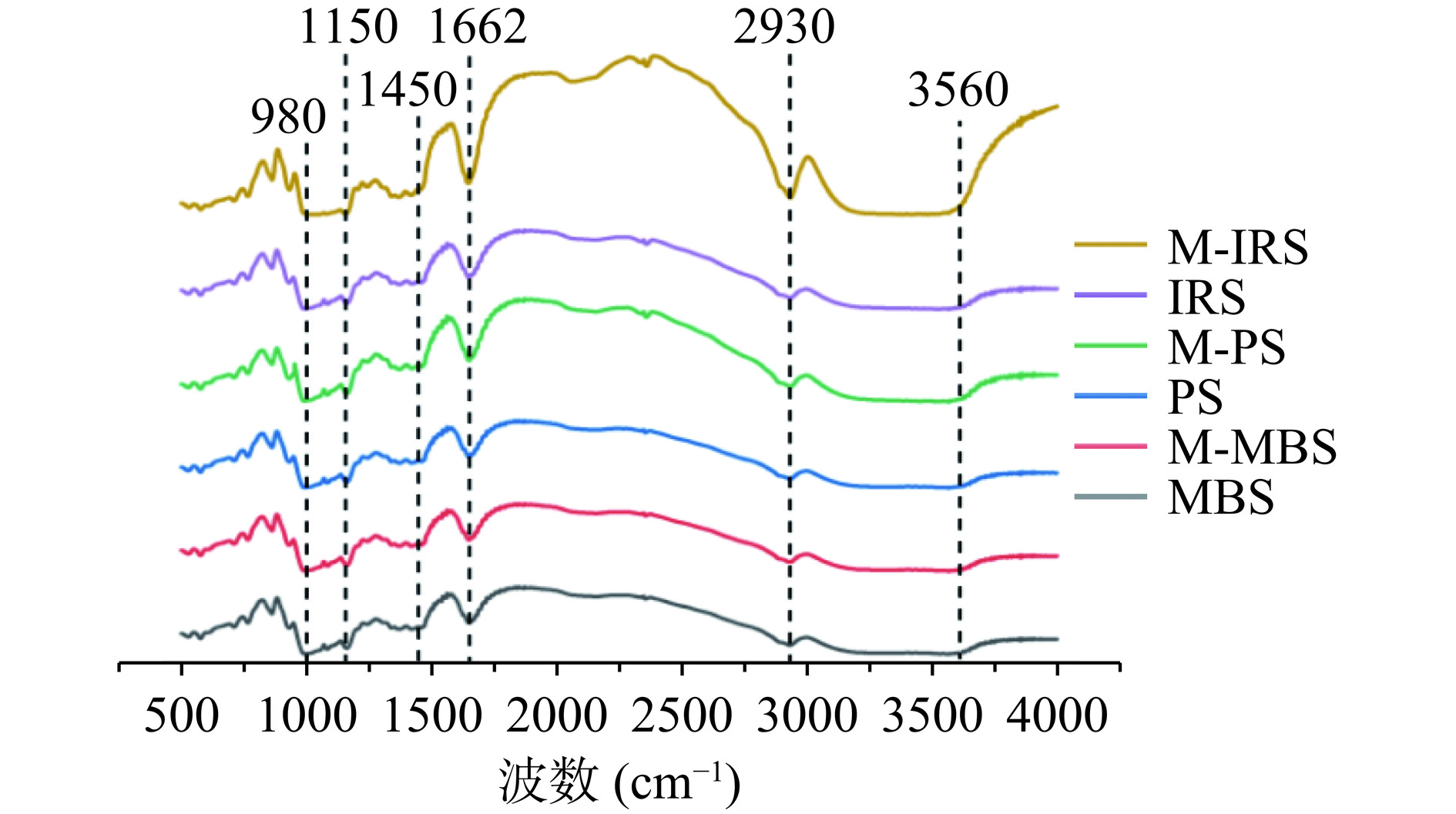

微波处理前后3种淀粉的红外扫描图见图4,主要出峰位置及官能团:3560 cm−1处的吸收峰为O-H伸缩振动,2930 cm−1处的吸收峰为CH2伸缩振动,1662 cm−1处的吸收峰为C-O-O伸缩振动,1450 cm−1处的吸收峰为CH2弯曲振动,1150 cm−1处的吸收峰为C-O和C-C伸缩振动,980 cm−1处吸收峰为C-OH的弯曲振动和C-O的伸缩振动[16,36]。总的来看,微波处理前后3种淀粉在4000~500 cm−1范围内具有相同的红外谱图波形,这表明微波不会使淀粉分子的化学键发生改变[37]。但从图4中可看出,吸收峰的强度有一定的差异,例如M-PS在1662 cm−1处的特征峰增强,以及M-IRS在2930 cm−1处的特征峰增强,这表明微波处理在一定程度上影响了淀粉的分子结构[38]。

2.7 微波处理对三种淀粉热特性的影响

如表4所示,MBS的起始、峰值、终值温度分别为61.3、70.26、82.29 ℃,经微波处理后,MBS的糊化温度均呈增加趋势,其中,微波处理前后的起始、峰值温度差异不显著(P>0.05),终值温度差异显著(P<0.05);PS的起始、峰值、终值温度分别为59.52、66.70、81.46 ℃,经微波处理后,PS的糊化温度均呈增加趋势,且存在显著性差异(P<0.05)。IRS的起始、峰值、终止温度分别为62.87、74.76、85.54 ℃,经微波处理后,IRS的糊化温度均呈增加趋势,且存在显著性差异(P<0.05)。由表4还可知,经微波处理后,MBS、PS、IRS的糊化焓值分别从原来的3.81、2.51、3.45 J/g降低至2.39、2.28、2.68 J/g,且存在显著性差异(P<0.05)。淀粉糊化温度的升高,主要是与微波后3种淀粉的直链淀粉含量升高有关,直链淀粉含量越高氢键的作用越强,破坏氢键所需的能量越多,因此糊化温度会升高[38],与前面直链淀粉含量和相对结晶度的测定结果相一致。而糊化焓值的降低,主要是由于微波破坏了淀粉颗粒中较脆弱的双螺旋结构并使其数量减少,导致其解旋能量的降低[37]。该结果与王雨生等[39]研究的微波处理玉米淀粉的结果一致。

表 4 微波处理前后三种淀粉的热力学参数Table 4. Thermodynamic parameters of three kinds of starch before and after microwave treatment样品名称 To(℃) TP(℃) TC(℃) ΔH(J/g) MBS 61.13±0.39Ac 70.26±0.24Ac 82.89±0.20Bc 3.81±0.18Aa M-MBS 61.25±0.09Ac 70.43±0.08Ac 85.03±0.06Ab 2.39±0.06Bd PS 59.52±0.10Be 66.70±0.13Be 81.46±0.37Be 2.51±0.03Acd M-PS 60.17±0.08Ad 68.12±0.18Ad 82.52±0.28Ad 2.28±0.03Bd IRS 62.87±0.12Bb 74.76±0.21Bb 85.54±0.20Bb 3.45±0.2Ab M-IRS 63.22±0.03Aa 75.19±0.17Aa 86.12±0.07Aa 2.68±0.21Bc 注:To:起始温度;Tp:峰值温度;Tc:终值温度;△H:糊化焓值。 2.8 微波处理对三种淀粉糊化特性的影响

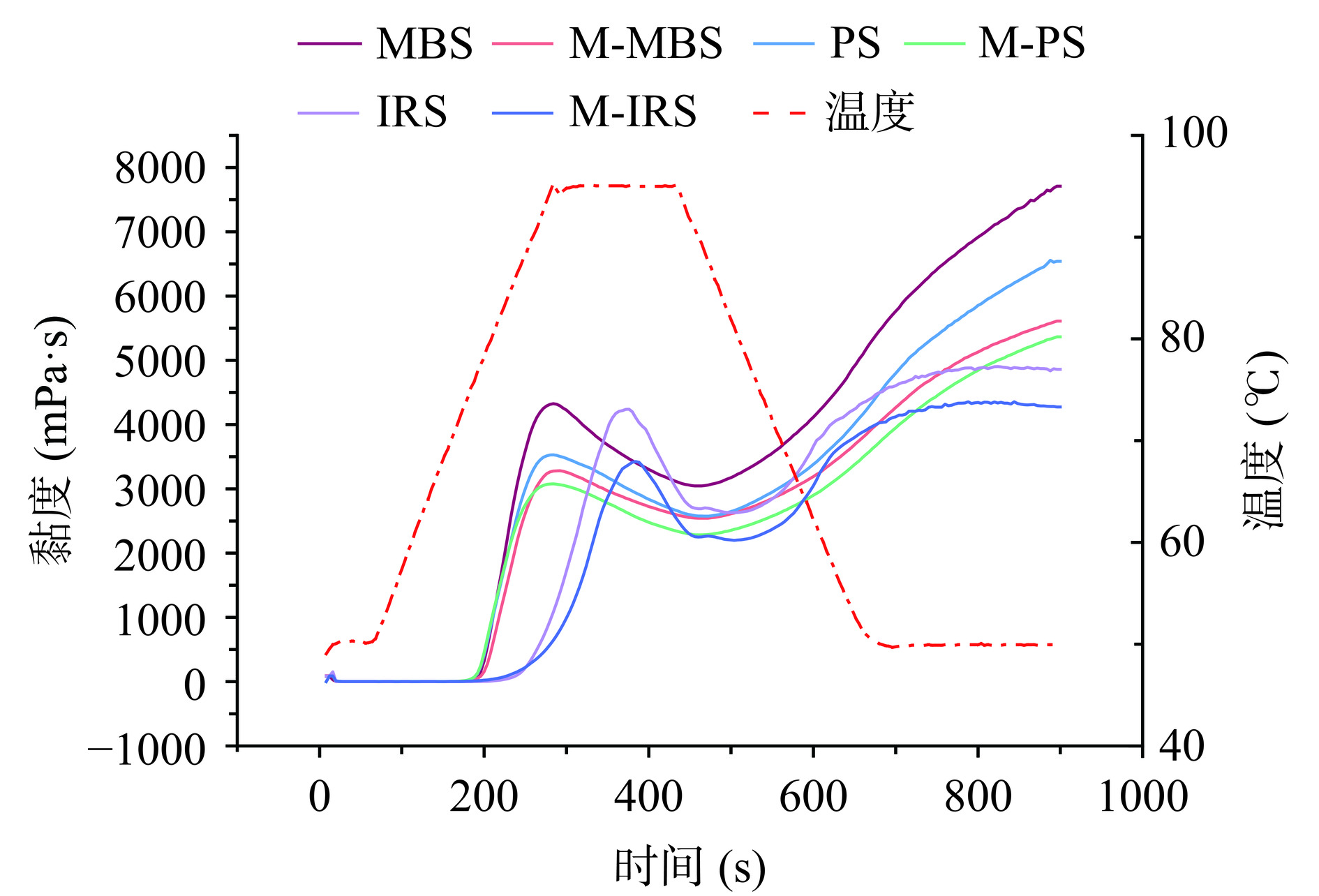

图5是RVA测得淀粉黏度变化的曲线图,具体参数见表5。从图5可以看出,微波前后3种淀粉的糊化曲线都具有淀粉糊化曲线的典型特征,说明微波处理没有完全破坏3种淀粉的结构[40]。由表5可知,经微波处理后,MBS的峰值黏度、谷值黏度、衰减值、回生值分别由原来的4324、3045、1279、4664 mPa·s降低至3283、2542、741、3069 mPa·s,PS的峰值黏度、谷值黏度、衰减值、回生值分别由原来的3530、2575、955、3966 mPa·s降低至3077、2284、793、3082 mPa·s,IRS的峰值黏度、谷值黏度、衰减值、回生值分别由原来的4238、2630、1608、2229 mPa·s降低至3424、2200、1224、2075 mPa·s,且微波处理前后3种淀粉的糊化黏度、衰减值、回生值均存在显著性差异(P<0.05)。经微波处理后,MBS、PS、IRS的糊化温度分别由原来的74.2、73.5、76.5 ℃增加至75.1、74.4、78.4 ℃,且存在显著性差异(P<0.05)。3种淀粉糊化黏度的降低,是由于微波处理降低了淀粉颗粒内部结构的紧密度,降低了结合水的能力,从而使分子间流动的黏性阻力减小[36]。回生值的降低说明原淀粉在短期内回生速率快。糊化温度的升高,主要是由于微波使淀粉的相对结晶度下降,从而导致其糊化温度的升高[15]。

表 5 微波处理前后三种淀粉的糊化特性参数Table 5. Gelatinization characteristics of three kinds of starch before and after microwave treatment淀粉种类 峰值黏度(mPa·s) 谷值黏度(mPa·s) 衰减值(mPa·s) 回生值(mPa·s) 糊化温度(℃) MBS 4324±11.00Aa 3045±7.81Aa 1279±11.79Ab 4664±5.62Aa 74.2±0.26Bd M-MBS 3283±5.25Be 2542±9.17Bc 741±28.72Bf 3069±5.77Bc 75.1±0.17Ac PS 3530±4.58Ac 2575±14.93Ac 955±9.54Ad 3966±10.82Ab 73.5±0.20Be M-PS 3077±9.64Bf 2284±31.00Bd 793±9.17Be 3082±9.93Bc 74.4±0.36Ad IRS 4238±13.53Ab 2630±25.12Ab 1608±24.43Aa 2229±4.72Ad 76.5±0.00Bb M-IRS 3424±15.88Bd 2200±16.82Be 1224±10.44Bc 2075±8.19Be 78.4±0.68Aa 2.9 微波处理对三种淀粉凝沉性的影响

由图6可知,随静置时间的增加,微波处理前后3种淀粉的澄清液体积均逐渐增加。总的来看,M-MBS、M-PS的凝沉速度要比MBS、PS快一些,M-IRS的凝沉速度也高于IRS,且微波处理后3种淀粉的凝沉体积百分比要低于原淀粉,这说明微波处理后的淀粉更易凝沉,凝沉稳定性更强,这与微波后淀粉直链淀粉含量升高有关[41],此结果与直链淀粉含量结果相一致。

3. 结论

采用微波手段处理绿豆淀粉、豌豆淀粉和籼米淀粉,比较分析微波处理前后3种淀粉的结构及理化性质的差异。结果表明,微波改性后,3种淀粉的直链淀粉含量显著增加(P<0.05);经微波处理后,3种淀粉虽保留着完整的颗粒结构,但颗粒表面均有不同程度的裂痕和破损,淀粉的偏光十字也半数以上消失。此外,微波处理后3种淀粉的晶型和官能团未发生改变,但相对结晶度、峰值黏度、谷值黏度、回生值、糊化焓值等均显著降低(P<0.05);微波后绿豆淀粉和豌豆淀粉的凝沉速度比籼米淀粉更快,且凝沉稳定性比籼米淀粉更好。

以上研究结果可知,微波处理会使3种淀粉结构和理化性质发生变化,而引起这些变化的具体原因则是微波产生的热能使淀粉内部发生部分糊化导致的直支链淀粉的互相转换。在本研究中的微波处理条件下,3种淀粉吸热开始发生部分糊化,随着支链淀粉的不断溶胀造成氢键断裂,形成了更多的短、中直链淀粉,从而导致淀粉的颗粒结构、结晶度及性质上的变化。综上,微波处理对3种淀粉的结构和理化性质具有显著的影响,可为淀粉的开发及应用提供一定的参考。

-

表 1 三种淀粉的基本成分

Table 1 Basic components of the three starches

样品 水分含量(%) 蛋白含量(%) 脂肪含量(%) 总淀粉含量(%) 直链淀粉含量(%) 支链淀粉含量(%) MBS 11.54±0.17a 1.22±0.04a 0.15±0.01ab 94.98±0.22a 36.78±0.30b 63.02±0.32b PS 11.88±0.24a 1.09±0.11a 0.18±0.03a 94.54±0.31a 40.29±0.13a 59.55±0.17c IRS 9.00±0.21b 0.88±0.05b 0.11±0.03b 94.02±0.13b 15.96±0.17c 84.27±0.25a 注:数据表现为均值±标准方差,同列不同上标小写字母表示差异显著(P<0.05)。 表 2 微波处理前后三种淀粉的直链淀粉含量

Table 2 Amylose content of three kinds of starch before and after microwave treatment

表 3 微波处理前后三种淀粉的相对结晶度

Table 3 Relative crystallinity of three kinds of starches before and after microwave treatment

样品 相对结晶度(%) 微波前 微波后 MBS 34.29±0.25Aa 27.26±0.10Ba PS 31.18±0.34Ab 26.24±0.37Bb IRS 28.29±0.35Ac 22.97±0.52Bc 表 4 微波处理前后三种淀粉的热力学参数

Table 4 Thermodynamic parameters of three kinds of starch before and after microwave treatment

样品名称 To(℃) TP(℃) TC(℃) ΔH(J/g) MBS 61.13±0.39Ac 70.26±0.24Ac 82.89±0.20Bc 3.81±0.18Aa M-MBS 61.25±0.09Ac 70.43±0.08Ac 85.03±0.06Ab 2.39±0.06Bd PS 59.52±0.10Be 66.70±0.13Be 81.46±0.37Be 2.51±0.03Acd M-PS 60.17±0.08Ad 68.12±0.18Ad 82.52±0.28Ad 2.28±0.03Bd IRS 62.87±0.12Bb 74.76±0.21Bb 85.54±0.20Bb 3.45±0.2Ab M-IRS 63.22±0.03Aa 75.19±0.17Aa 86.12±0.07Aa 2.68±0.21Bc 注:To:起始温度;Tp:峰值温度;Tc:终值温度;△H:糊化焓值。 表 5 微波处理前后三种淀粉的糊化特性参数

Table 5 Gelatinization characteristics of three kinds of starch before and after microwave treatment

淀粉种类 峰值黏度(mPa·s) 谷值黏度(mPa·s) 衰减值(mPa·s) 回生值(mPa·s) 糊化温度(℃) MBS 4324±11.00Aa 3045±7.81Aa 1279±11.79Ab 4664±5.62Aa 74.2±0.26Bd M-MBS 3283±5.25Be 2542±9.17Bc 741±28.72Bf 3069±5.77Bc 75.1±0.17Ac PS 3530±4.58Ac 2575±14.93Ac 955±9.54Ad 3966±10.82Ab 73.5±0.20Be M-PS 3077±9.64Bf 2284±31.00Bd 793±9.17Be 3082±9.93Bc 74.4±0.36Ad IRS 4238±13.53Ab 2630±25.12Ab 1608±24.43Aa 2229±4.72Ad 76.5±0.00Bb M-IRS 3424±15.88Bd 2200±16.82Be 1224±10.44Bc 2075±8.19Be 78.4±0.68Aa -

[1] 陈颖, 陈勉, 王瓛, 等. 几种淀粉的相对分子质量分布、微晶结构及形貌的研究[J]. 中国粮油学报,2014,29(3):19−23. [CHEN Ying, CHEN Mian, WANG Huan, et al. Molecular weight distribution, structures and microscopic morphology of several diferent starches[J]. Journal of the Chinese Cereals and Oils Association,2014,29(3):19−23.] CHEN Ying, CHEN Mian, WANG Huan, et al. Molecular weight distribution, structures and microscopic morphology of several diferent starches[J]. Journal of the Chinese Cereals and Oils Association, 2014, 29(3): 19−23.

[2] 张正茂, 王志华, 颜永斌, 等. 不同来源淀粉的糊化特性研究[J]. 食品工业,2016,37(6):141−145. [ZHANG Zhengmao, WANG Zhihua, YAN Yongbin, et al. Pasting properties of starch from different sources[J]. Science and Technology of Food Industry,2016,37(6):141−145.] ZHANG Zhengmao, WANG Zhihua, YAN Yongbin, et al. Pasting properties of starch from different sources[J]. Science and Technology of Food Industry, 2016, 37(6): 141−145.

[3] 孙庆杰, 徐子慧, 孙琪, 等. 湿热处理对羟丙基淀粉结构特性及凝胶性能的影响[J]. 粮油食品科技,2024,32(2):37−45,10. [SUN Qingjie, XU Zhihui, SU Qi, et al. Effect of heat-moisture treatment on the structure and gel properties of hydroxypropyl starch[J]. Science and Technology of Cereals, Oils and Foods,2024,32(2):37−45,10.] SUN Qingjie, XU Zhihui, SU Qi, et al. Effect of heat-moisture treatment on the structure and gel properties of hydroxypropyl starch[J]. Science and Technology of Cereals, Oils and Foods, 2024, 32(2): 37−45,10.

[4] 苏键, 李振玉. 几种不同来源淀粉的水合特性和糊化特性研究[J]. 粮食与油脂,2022,35(8):43−46,56. [SU Jian, LI Zhenyu. Study on hydration and gelatinization properties of starch from different source[J]. Cereals and Oils,2022,35(8):43−46,56.] SU Jian, LI Zhenyu. Study on hydration and gelatinization properties of starch from different source[J]. Cereals and Oils, 2022, 35(8): 43−46,56.

[5] 周淑蓝, 叶发银, 赵国华, 等. 绿豆淀粉的性质、改性及其应用[J]. 中国食品学报,2022,22(4):450−461. [ZHOU Shulan, YE Fayin, ZHAO Guohua, et al. The properties, modification and application of mung bean(Vigna radiaya L. Wilczek) starch[J]. Journal of Chinese Institute of Food Science and Technology,2022,22(4):450−461.] ZHOU Shulan, YE Fayin, ZHAO Guohua, et al. The properties, modification and application of mung bean(Vigna radiaya L. Wilczek) starch[J]. Journal of Chinese Institute of Food Science and Technology, 2022, 22(4): 450−461.

[6] 王艳, 张煜松, 刘兴丽, 等. 湿热处理对绿豆淀粉结构及理化特性的影响[J]. 轻工学报,2022,37(3):36−42. [WANG Yan, ZHANG Yusong, LIU Xingli, et al. Effect of heat moisture treatment on the structural and physicochemical properties of mung bean starch[J]. Journal of Light Industry,2022,37(3):36−42.] doi: 10.12187/2022.03.005 WANG Yan, ZHANG Yusong, LIU Xingli, et al. Effect of heat moisture treatment on the structural and physicochemical properties of mung bean starch[J]. Journal of Light Industry, 2022, 37(3): 36−42. doi: 10.12187/2022.03.005

[7] 张晓磊, 刘鹏飞, 代养勇, 等. 超声处理对豌豆淀粉结构及热力学性质的影响[J]. 粮食与油脂,2023,36(6):30−34. [ZHANG Xiaolei, LIU Pengfei, DAI Yangyong, et al. Effect of ultrasonic treatment on the structure and thermodynamic properties of pea starch[J]. Cereals and Oils,2023,36(6):30−34.] doi: 10.3969/j.issn.1008-9578.2023.06.008 ZHANG Xiaolei, LIU Pengfei, DAI Yangyong, et al. Effect of ultrasonic treatment on the structure and thermodynamic properties of pea starch[J]. Cereals and Oils, 2023, 36(6): 30−34. doi: 10.3969/j.issn.1008-9578.2023.06.008

[8] 胡荣, 汪楠, 张甫生, 等. 高压均质处理对豌豆淀粉流变特性及多尺度结构的影响[J]. 食品科学,2023,44(5):53−61. [HU Rong, WANG Nan, ZHANG Fusheng, et al. Effect of high-pressure homogenization on rheological properties and multiscale structure of pea starch[J]. Food Science,2023,44(5):53−61.] doi: 10.7506/spkx1002-6630-20220513-164 HU Rong, WANG Nan, ZHANG Fusheng, et al. Effect of high-pressure homogenization on rheological properties and multiscale structure of pea starch[J]. Food Science, 2023, 44(5): 53−61. doi: 10.7506/spkx1002-6630-20220513-164

[9] 王静雯, 吕雅文, 尚亚卓, 等. 大米淀粉膜的制备及其性能[J]. 应用化学,2022,39(11):1693−1702. [WANG Jingwen, LÜ Yawen, SHANG Yazhuo, et al. Preparation and properties of rice starch film[J]. Chinese Journal of Applied Chemistry,2022,39(11):1693−1702.] WANG Jingwen, LÜ Yawen, SHANG Yazhuo, et al. Preparation and properties of rice starch film[J]. Chinese Journal of Applied Chemistry, 2022, 39(11): 1693−1702.

[10] OH I K, BAE I Y, LEE H G. Effect of dry heat treatment on physical property and in vitro starch digestibility of high amylose rice starch[J]. International Journal of Biological Macromolecules,2018,108:568−575. doi: 10.1016/j.ijbiomac.2017.11.180

[11] 刘传菊, 李欢欢, 汤尚文, 等. 大米淀粉结构与特性研究进展[J]. 中国粮油学报,2019,34(12):107−114. [LIU Chuanjun, LI Huanhuan, TANG Shangwen, et al. A review on structures and properties of rice starch[J]. Journal of the Chinese Cereals and Oils Association,2019,34(12):107−114.] doi: 10.3969/j.issn.1003-0174.2019.12.018 LIU Chuanjun, LI Huanhuan, TANG Shangwen, et al. A review on structures and properties of rice starch[J]. Journal of the Chinese Cereals and Oils Association, 2019, 34(12): 107−114. doi: 10.3969/j.issn.1003-0174.2019.12.018

[12] ZHU F. Barley starch:Composition, structure, properties, and modifications[J]. Comprehensive Reviews in Food Science and Food Safety,2017,16(4):558−579. doi: 10.1111/1541-4337.12265

[13] 江敏仪, 吴志成, 相红丽, 等. 微波处理对食品营养成分的影响研究[J]. 食品安全导刊,2022(33):129−131. [JIANG Minyi, WU Zhicheng, XIANG Hongli, et al. Study on the influence of microwave treatment on the nutritional composition of food[J]. China Food Safety Magazine,2022(33):129−131.] doi: 10.3969/j.issn.1674-0270.2022.33.spaqdk202233039 JIANG Minyi, WU Zhicheng, XIANG Hongli, et al. Study on the influence of microwave treatment on the nutritional composition of food[J]. China Food Safety Magazine, 2022(33): 129−131. doi: 10.3969/j.issn.1674-0270.2022.33.spaqdk202233039

[14] 李世杰, 段春月, 刘畅, 等. 微波对板栗淀粉结构和理化性质的影响[J]. 中国粮油学报,2020,35(2):31−35, 49. [LI Shijie, DUAN Chunyue, LIU Chang, et al. Effects of microwave treatment on structural and physicochemical properties of chestnut starch[J]. Journal of the Chinese Cereals and Oils Association,2020,35(2):31−35, 49.] doi: 10.3969/j.issn.1003-0174.2020.02.007 LI Shijie, DUAN Chunyue, LIU Chang, et al. Effects of microwave treatment on structural and physicochemical properties of chestnut starch[J]. Journal of the Chinese Cereals and Oils Association, 2020, 35(2): 31−35, 49. doi: 10.3969/j.issn.1003-0174.2020.02.007

[15] OYEYINKA S A, UMARU E, OLATUNDE S J, et al. Effect of short microwave heating time on physicochemical and functional properties of Bambara groundnut starch[J]. Food Bioscience,2019,28:36−41. doi: 10.1016/j.fbio.2019.01.005

[16] 武云娇, 王一飞, 魏明智, 等. 微波复合酶解改性对小米淀粉结构表征及其理化特性的影响[J]. 中国粮油学报,2023,38(11):44−51. [WU Yunjiao, WANG Yifei, WEI Mingzhi, et al. Effect of microwave complex enzymatic digestion on the structural and physicochemical properties of millet starch[J]. Journal of the Chinese Cereals and Oils Association,2023,38(11):44−51.] WU Yunjiao, WANG Yifei, WEI Mingzhi, et al. Effect of microwave complex enzymatic digestion on the structural and physicochemical properties of millet starch[J]. Journal of the Chinese Cereals and Oils Association, 2023, 38(11): 44−51.

[17] ANDERSON A K, GURAYA H S. Effects of microwave heat-moisture treatment on properties of waxy and non-waxy rice starches[J]. Food Chemistry,2006,97(2):318−323. doi: 10.1016/j.foodchem.2005.04.025

[18] ZHONG Y, XIANG X, ZHAO J, et al. Microwave pretreatment promotes the annealing modification of rice starch[J]. Food Chemistry,2020,304:125432. doi: 10.1016/j.foodchem.2019.125432

[19] 林国荣, 张丽芬, 黄晓玲, 等. 微波处理对枇杷核淀粉理化性质和消化性能的影响[J]. 食品工业科技,2023,44(15):55−61. [LIN Guorong, ZHANG Lifen, HUANG Xiaoling, et al. Effect of microwave treatment on the physicochemical and digestive properties of loquat kernel starch[J]. Science and Technology of Food Industry,2023,44(15):55−61.] LIN Guorong, ZHANG Lifen, HUANG Xiaoling, et al. Effect of microwave treatment on the physicochemical and digestive properties of loquat kernel starch[J]. Science and Technology of Food Industry, 2023, 44(15): 55−61.

[20] 唐小闲, 汤泉, 段振华, 等. 微波间歇干燥与热风干燥对马蹄淀粉特性的影响[J]. 食品研究与开发,2018,39(7):71−75. [TANG Xiaoxian, TANG Quan, DUAN Zhenhua, et al. Studies on the characteristics of intermittent microwave drying and hot air drying of water chestnut starch[J]. Food Research and Development,2018,39(7):71−75.] doi: 10.3969/j.issn.1005-6521.2018.07.012 TANG Xiaoxian, TANG Quan, DUAN Zhenhua, et al. Studies on the characteristics of intermittent microwave drying and hot air drying of water chestnut starch[J]. Food Research and Development, 2018, 39(7): 71−75. doi: 10.3969/j.issn.1005-6521.2018.07.012

[21] 张晶, 张美莉. 超高压处理对燕麦淀粉颗粒特性、热特性及流变学特性的影响[J]. 食品科学,2020,41(23):114−121. [ZHANG Jing, ZHANG Meili, et al. Effect of high hydrostatic pressure treatment on morphological, thermal and rheological properties of oat starch[J]. Food Science,2020,41(23):114−121.] doi: 10.7506/spkx1002-6630-20190908-106 ZHANG Jing, ZHANG Meili, et al. Effect of high hydrostatic pressure treatment on morphological, thermal and rheological properties of oat starch[J]. Food Science, 2020, 41(23): 114−121. doi: 10.7506/spkx1002-6630-20190908-106

[22] WEI B, CAI C, XU B, et al. Disruption and molecule degradation of waxy maize starch granules during high pressure homogenization process[J]. Food Chemistry,2018,240:165−173. doi: 10.1016/j.foodchem.2017.07.078

[23] LI L, YUAN T Z, SETIA R, et al. Characteristics of pea, lentil and faba bean starches isolated from air-classified flours in comparison with commercial starches[J]. Food Chemistry,2019,276:599−607. doi: 10.1016/j.foodchem.2018.10.064

[24] 张吉军, 曹龙奎, 衣淑娟, 等. 微波间歇干燥对北方粳高粱蛋白质及淀粉品质的影响[J]. 食品科学,2022,43(7):52−60. [ZHANG Jijun, CAO Longkui, YI Shujuan, et al. Effect of intermittent microwave drying on protein and starch quality of Non-glutinous Sorghum[J]. Food Science,2022,43(7):52−60.] doi: 10.7506/spkx1002-6630-20201225-293 ZHANG Jijun, CAO Longkui, YI Shujuan, et al. Effect of intermittent microwave drying on protein and starch quality of Non-glutinous Sorghum[J]. Food Science, 2022, 43(7): 52−60. doi: 10.7506/spkx1002-6630-20201225-293

[25] CAO S, YU Y, YIN Y, et al. Combination mechanism and structural properties of complexes between lipid and small granule starch isolated from Agriophyllum squarrosum (L.) Moq. seeds[J]. Starch-Stärke,2022,74(7-8):2100215.

[26] 翟娅菲, 刘秀妨, 张华, 等. 藜麦淀粉理化特性研究[J]. 食品工业科技,2017,38(24):48−52,57. [ZHAI Yafei, LIU Xiufang, ZHANG Hua, et al. Study on the physicochemical properties of quinoa starch[J]. Science and Technology of Food Industry,2017,38(24):48−52,57.] ZHAI Yafei, LIU Xiufang, ZHANG Hua, et al. Study on the physicochemical properties of quinoa starch[J]. Science and Technology of Food Industry, 2017, 38(24): 48−52,57.

[27] 琚魏波, 柳青山, 白文斌, 等. 山西不同品种高粱淀粉特性[J]. 中国粮油学报,2024,39(6):103−110. [JU Weibo, LIU Qingshan, BAI Wenbin, et al. Starch characteristics of different varieties of sorghum in Shanxi[J]. Journal of the Chinese Cereals and Oils Association,2024,39(6):103−110.] JU Weibo, LIU Qingshan, BAI Wenbin, et al. Starch characteristics of different varieties of sorghum in Shanxi[J]. Journal of the Chinese Cereals and Oils Association, 2024, 39(6): 103−110.

[28] 刘宁, 张铁鹏, 刘涛, 等. 豆类淀粉的研究进展[J]. 包装工程,2020,41(7):58−64. [LIU Ning, ZHANG Tiepeng, LIU Tao, et al. Research progress of bean starch[J]. Packaging Engineering,2020,41(7):58−64.] LIU Ning, ZHANG Tiepeng, LIU Tao, et al. Research progress of bean starch[J]. Packaging Engineering, 2020, 41(7): 58−64.

[29] CHAN H T, BHAT R, KARIM A A. Effects of sodium dodecyl sulphate and sonication treatment on physicochemical properties of starch[J]. Food Chemistry,2010,120(3):703−709. doi: 10.1016/j.foodchem.2009.10.066

[30] 袁璐, 胡婕伦, 殷军艺. 微波辐射对大米淀粉理化性质和结构特性的影响[J]. 南昌大学学报(理科版),2020,44(6):544−550. [YUAN Lu, HU Jielun, YIN Junyi, et al. Effect of microwave radiation on physicochemical properties and structural characteristics of rice starch[J]. Journal of Nanchang University (Natural Science),2020,44(6):544−550.] doi: 10.3969/j.issn.1006-0464.2020.06.007 YUAN Lu, HU Jielun, YIN Junyi, et al. Effect of microwave radiation on physicochemical properties and structural characteristics of rice starch[J]. Journal of Nanchang University (Natural Science), 2020, 44(6): 544−550. doi: 10.3969/j.issn.1006-0464.2020.06.007

[31] 王萌. 超声波和微波双重处理对淀粉理化性质和功能性质的影响[D]. 北京:北京林业大学, 2022. [WANG Meng. Effect of ultrasonic and microwave dual-treatment on the physicochemical and functional properties of starch[D]. Beijing:Beijing Forestry University, 2022.] WANG Meng. Effect of ultrasonic and microwave dual-treatment on the physicochemical and functional properties of starch[D]. Beijing: Beijing Forestry University, 2022.

[32] 侯蕾, 韩小贤, 郑学玲, 等. 不同直链淀粉含量玉米淀粉研究进展[J]. 粮食与油脂,2013,26(6):11−14. [HOU Lei, HAN Xiaoxian, ZHENG Xueling, et al. Research advance on corn starch with different content of amylose[J]. Cereals and Oils,2013,26(6):11−14.] doi: 10.3969/j.issn.1008-9578.2013.06.006 HOU Lei, HAN Xiaoxian, ZHENG Xueling, et al. Research advance on corn starch with different content of amylose[J]. Cereals and Oils, 2013, 26(6): 11−14. doi: 10.3969/j.issn.1008-9578.2013.06.006

[33] 陈平生, 黄智君, 王娟, 等. 不同热处理方式对大蕉抗性淀粉理化性质的影响[J]. 现代食品科技,2012,28(1):9−13, 51. [CHEN Pingsheng, HUANG Zhijun, WANG Juan, et al. Effects of different heat treatments on the physicochemical properties of plantain resistant starch[J]. Modern Food Science and Technology,2012,28(1):9−13, 51.] CHEN Pingsheng, HUANG Zhijun, WANG Juan, et al. Effects of different heat treatments on the physicochemical properties of plantain resistant starch[J]. Modern Food Science and Technology, 2012, 28(1): 9−13, 51.

[34] 张明. 湿热协同微波处理对淀粉理化性质及消化性的影响[D]. 广州:华南理工大学, 2015. [ZHANG Ming. Effect of heat-moisture combined with microwave treatment on physicochemical and digestibility property of starch[D]. Guangzhou:South China University of Technology, 2015.] ZHANG Ming. Effect of heat-moisture combined with microwave treatment on physicochemical and digestibility property of starch[D]. Guangzhou: South China University of Technology, 2015.

[35] 郑玉玉, 杨晔, 尹登科, 等. 微波对玉米淀粉结构及理化性质的影响[J]. 食品科学,2022,43(11):99−104. [ZHENG Yuyu, YANG Ye, YIN Dengke, et al. Effect of microwave on the structure and physicochemical properties of maize starch[J]. Food Science,2022,43(11):99−104.] doi: 10.7506/spkx1002-6630-20211022-242 ZHENG Yuyu, YANG Ye, YIN Dengke, et al. Effect of microwave on the structure and physicochemical properties of maize starch[J]. Food Science, 2022, 43(11): 99−104. doi: 10.7506/spkx1002-6630-20211022-242

[36] 雷宁宇, 卢楹, 宋萧萧, 等. 不同压力下蒸煮处理对鹰嘴豆淀粉结构及理化特性的影响[J]. 食品科学,2023,44(15):80−86. [LEI Ningyu, LU Ying, SONG Xiaoxiao, et al. Effects of cooking treatments under different pressures on the structure and physicochemical properties of chickpea starch[J]. Food Science,2023,44(15):80−86.] LEI Ningyu, LU Ying, SONG Xiaoxiao, et al. Effects of cooking treatments under different pressures on the structure and physicochemical properties of chickpea starch[J]. Food Science, 2023, 44(15): 80−86.

[37] 刘佳男, 于雷, 王婷, 等. 微波处理对白高粱淀粉理化特性的影响[J]. 食品科学,2017,38(5):186−190. [LIU Jianan, YU Lei, WANG Ting, et al. Effect of microwave treatment on physicochemical properties of white sorghum starch[J]. Food Science,2017,38(5):186−190.] doi: 10.7506/spkx1002-6630-201705030 LIU Jianan, YU Lei, WANG Ting, et al. Effect of microwave treatment on physicochemical properties of white sorghum starch[J]. Food Science, 2017, 38(5): 186−190. doi: 10.7506/spkx1002-6630-201705030

[38] 程新峰, 杭华, 肖子群, 等. 微波辐射下淀粉的响应机制及研究现状[J]. 食品科学,2018,39(13):310−316. [CHENG Xinfeng, HANG Hua, XIAO Ziqun, et al. Current status of research on the mechanism of action and effect of microwave irradiation on starch[J]. Food Science,2018,39(13):310−316.] doi: 10.7506/spkx1002-6630-201813046 CHENG Xinfeng, HANG Hua, XIAO Ziqun, et al. Current status of research on the mechanism of action and effect of microwave irradiation on starch[J]. Food Science, 2018, 39(13): 310−316. doi: 10.7506/spkx1002-6630-201813046

[39] 王雨生, 秦福敏, 陈海华, 等. 微波处理对普通玉米淀粉和蜡质玉米淀粉理化性质的影响[J]. 中国粮油学报,2016,31(12):18−24,28. [WANG Yusheng, QIN Fumin, CHEN Haihua, et al. Effect of microwave treatment on physicochemical properties of common corn starch and waxy corn starch[J]. Journal of the Chinese Cereals and Oils Association,2016,31(12):18−24,28.] doi: 10.3969/j.issn.1003-0174.2016.12.004 WANG Yusheng, QIN Fumin, CHEN Haihua, et al. Effect of microwave treatment on physicochemical properties of common corn starch and waxy corn starch[J]. Journal of the Chinese Cereals and Oils Association, 2016, 31(12): 18−24,28. doi: 10.3969/j.issn.1003-0174.2016.12.004

[40] ASHOGBON A O, AKINTAYO E T, OLADEBEYE A O, et al. Developments in the isolation, composition, and physicochemical properties of legume starches[J]. Critical Reviews in Food Science and Nutrition,2021,61(17):2938−2959. doi: 10.1080/10408398.2020.1791048

[41] 郭爱良, 周湘寒, 姚亚亚, 等. 不同玉米品种理化特性及淀粉品质的研究[J]. 中国粮油学报,2022,37(5):39−47. [GUO Ailiang, ZHOU Xianghan, YAO Yaya, et al. Physicochemical properties and starch quality of different corn varieties[J]. Journal of the Chinese Cereals and Oils Association,2022,37(5):39−47.] doi: 10.3969/j.issn.1003-0174.2022.05.007 GUO Ailiang, ZHOU Xianghan, YAO Yaya, et al. Physicochemical properties and starch quality of different corn varieties[J]. Journal of the Chinese Cereals and Oils Association, 2022, 37(5): 39−47. doi: 10.3969/j.issn.1003-0174.2022.05.007

下载:

下载:

下载:

下载: