Effect of Adding Large-leaf Yellow Powder with Different Particle Sizes on The Quality Characteristics of Dough

-

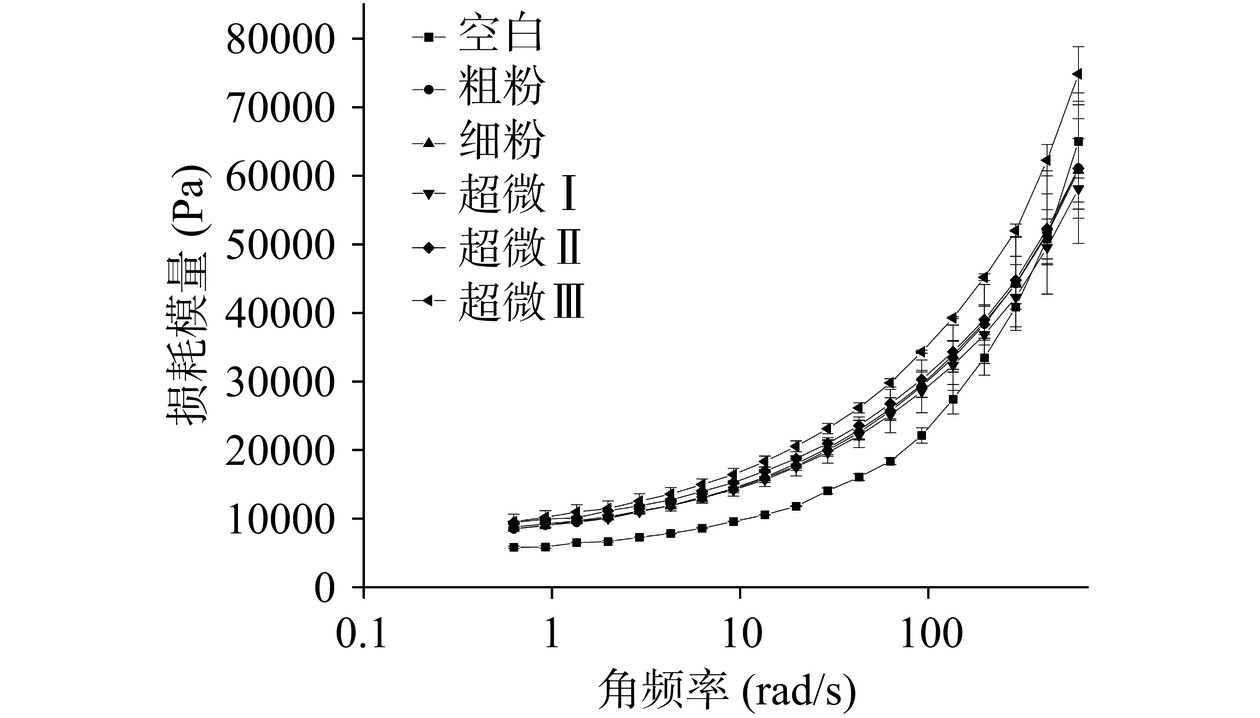

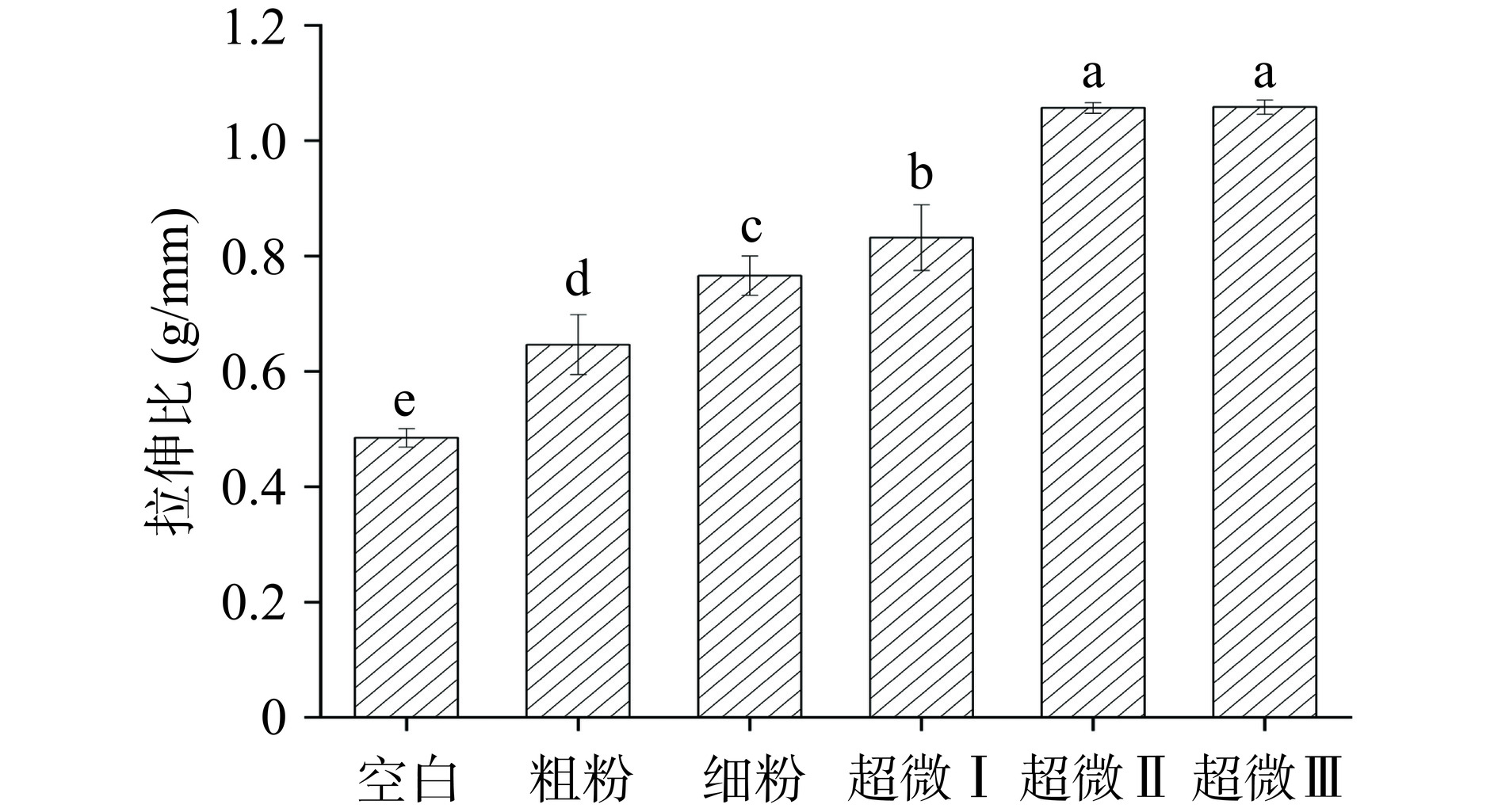

摘要: 为探究不同粒度黄大茶粉对小麦面团品质特性的影响,本研究选取粗粉、细粉、超微Ⅰ、超微Ⅱ和超微Ⅲ 5种茶粉分别等量加入到面粉中制成含茶面团。采用粉质仪、质构仪、流变仪、快速粘度分析仪等仪器分析不同粉体对面团品质特性的影响。结果显示,随着黄大茶粒度的减小,面团的吸水率、形成时间和稳定时间显著提高(P<0.05),而混合面团的储能模量(G')和损耗模量(G'')值提高,且G'值占主导地位。蛋白弱化度、峰值黏度、回生值和糊化焓主要呈现下降趋势,拉伸阻力和拉伸长度先上升后下降。本研究显示添加不同粒度的黄大茶粉会对小麦面团品质特性产生影响。尤其是超微Ⅱ的添加能够有效改善面团的热机械学及流变特性。本研究结果有望为含茶面制品的开发利用提供参考依据。Abstract: To investigate the effect of different particle sizes of large-leaf yellow tea powder on the quality characteristics of wheat dough, this study selected five types of tea powder, namely coarse powder, fine powder, ultra-fine I, ultra-fine II, and ultra-fine III, and added them in equal amounts to the flour to make tea containing dough. The influence of different powders on the quality characteristics of wheat dough was analyzed using instruments such as farinograph, texture analyzer, rheometer, and rapid viscosity analyzer. The results showed that as the particle size of large-leaf yellow tea decreased, the water absorption rate, formation time, and stability time of the dough significantly increased (P<0.05), while the storage modulus (G') and loss modulus (G'') of the mixed dough increased, and G' value dominated. The protein weakening degree, peak viscosity, retrogradation value, and gelatinization enthalpy mainly showed a decreasing trend, while the tensile resistance and tensile length first increased and then decreased. This study showed that adding different particle sizes of large-leaf yellow powder could affect the quality characteristics of wheat dough. Especially, the addition of ultra-fine II could effectively improve the thermal mechanical and rheological properties of dough. The results of this study are expected to provide reference for the development and utilization of tea containing flour products.

-

黄大茶是一种轻微发酵黄茶,多选用粗老茶叶原料进行加工,其加工步骤主要包含固色、轧制、黄化、干燥等工艺[1]。茶叶黄化通常需要经过闷黄工艺制作而成,而这个在高温高湿的加工过程中,外源酶和湿热结合导致茶的化学成分改变,从而产生独特的“锅巴香”风味[2−3]。目前研究显示,黄大茶具有良好降血糖血脂、抗氧化、调节肠道菌群等[4−5]功效。

目前茶叶经粉碎加工制成的茶粉已作为食品添加原料而广泛应用于面条、馒头、糕点等面制品中。而面团中添加不同原料会影响面制品的品质特性。近年来研究显示,将膳食纤维、蔬菜、水果等原料加入面粉制成复合型面制品,可以提升面制品的营养功能[6]。而目前报道相对较多的食品添加原料主要有黄秋葵[7]、食叶草[8]、银杏[9]、香菇[10]等。冉隆贵等[11]研究绿茶、红茶和黑茶三种茶粉对小麦面粉流变学及糊化特性的影响,结果显示三类茶叶粉对面粉糊化的热稳定性具有不同程度的改善作用。汪金萍等[12]研究抹茶粉对面团流变学特性及面条品质的影响,结果显示,抹茶粉添加量为6%时,面团的回生值、形成时间和稳定值相对较好,能够抑制混合面团的老化,且面筋网络结构较为适中。目前的研究多集中于添加茶叶对面团特性的影响,而对其粉碎粒度变化影响面团特性的相关研究还少见报道。冷进松等[13]研究不同粒度紫苏粕对面团流变学特性的影响,结果显示,紫苏粕粒度较小时,面团的吸水率、稳定时间、拉伸阻力、拉伸长度较高,紫苏粉粒度对面团的流变学特性有显著影响。王君荣等[14]研究证明,随着荞麦麸皮粒度的减小,面团稳定时间上升,弱化度降低,面团特性有所改变。

本研究以黄大茶为原料,将黄大茶粗粉、细粉、超微Ⅰ、超微Ⅱ和超微Ⅲ 5种粉体以一定的替代率加入到面粉中,探讨不同粒度的黄大茶粉对面团特性的影响,以期为含茶面制品的改良提供理论参考。

1. 材料与方法

1.1 材料与仪器

大叶黄茶 安徽省抱儿钟秀茶叶股份有限公司;高筋小麦粉(蛋白质12.2 g/100 g、脂肪1.0 g/100 g、碳水化合物70.9 g/100 g) 潍坊风筝面粉有限责任公司。

Mixolab混合实验仪 法国肖邦技术有限公司;F4流变发酵仪 法国Chopin公司;TA-XTPlus质构仪 苏州市三昊仪器设备有限公司;球磨粉碎机 长沙米淇仪器设备有限公司;Gamma 1-16冷冻干燥机 德国Christ公司。

1.2 实验方法

1.2.1 黄大茶粉的制备

将干燥的黄大茶放入粉碎机粉碎,分别过20目、100目标准筛,制备成黄大茶粗粉、细粉,再将黄大茶粉放入到球磨粉碎机中进行超微粉碎,粉碎时间分别设定为1、2、3 h,得到超微粉Ⅰ、超微粉Ⅱ和超微粉Ⅲ。

1.2.2 黄大茶粉添加量选择

以50 g面粉为基准,其他条件均相同粒度的情况下,称取黄大茶粉添加量1%、3%、5%、7%、9%混合。实验采用P36R探头,测试前中后速度皆为2 mm/s,触发力5 g,压缩程度为50%,压缩2次,对面团的硬度进行分析。

1.2.3 黄大茶粉粒度测定

准确称取0.5 g的黄大茶粉样品放入50 mL的纯水中分散均匀,通过激光粒度仪分析测量黄大茶粉的平均粒度大小及分布,颗粒折射率为1.5,分散剂折射率为1.33,以D(0.1)、D(0.5)和D(0.9)、D(3,4)来表示结果。

1.2.4 茶多酚含量测定

选取没食子酸为标准品来作标准曲线,制备好1 mg/mL的标准溶液。分别取1.0、2.0、3.0、4.0、5.0 mL稀释并定容至100 mL。分别吸取1 mL加入5个25 mL比色管,先后加入1.0 mL 0.1 mol/L福林酚溶液和4.0 mL 7.5%Na2CO3溶液,混匀后用浓度60%乙醇溶液定容。1.5 h避光处理,以不加入没食子酸的实验组为标准比色溶液,测定其在765 nm下吸光值,绘制标准曲线。将粗提物用相应质量分数乙醇水溶液定容至100 mL,从中取1 mL于25 mL比色管中,先后加入1 mL福林酚和4 mL 7.5%Na2CO3溶液,混合均匀后用60%乙醇水溶液定容避光反应1.5 h,以纯水调零,在765 nm波长处测得吸光值。

w(%)=CVNM×1000×1000×100 (1) 式中:w为样品中茶多酚含量,%;V为提取液定容后体积,mL;C为测出的茶多酚质量浓度,μg/mL;M为粉末质量,g;N为稀释倍数,1000为单位换算。

1.2.5 茶多糖含量测定

称取0.100 g经105 ℃烘干后的葡萄糖,将其溶解,定容至100 mL,得到葡萄糖标准储液。量取2.0、4.0、6.0、8.0、10.0 mL葡萄糖标准储液至于100 mL容量瓶中,用水定容后得到质量浓度为20、40、60、80、100 μg/mL的葡萄糖标准液。量取0.5 mL标准品溶液于15 mL试管中,加入0.5 mL 6%(质量分数)苯酚溶液,再加入2.5 mL浓硫酸,摇匀,纯水作空白对照。静置30 min后测490 nm处的吸光度(A),以葡萄糖浓度(μg/mL)为横坐标,吸光度为纵坐标,绘制标准曲线。准确称取0.4 g(精确到0.0001 g)匀质样品粉末于250 mL锥形瓶中,加沸蒸馏水100 mL,立即移入沸水浴中,磁力搅拌浸提45 min,浸提完毕后立即趁热减压过滤,残渣用少量热蒸馏水洗涤2~3次,将滤液移入250 mL容量瓶中,冷却后用水定容至刻度,摇匀,按标准曲线方法测定。

w(%)=m1×v1m2×v2×100 (2) 式中:w为样品中茶多糖含量,%;m1为从标准曲线上查得样品测定液中的茶多糖含量,μg;v1为样品定容体积,mL;m2为样品质量,μg;v2为比色测定时移取样品测定液的体积,mL。

1.2.6 微观结构

用扫描电子显微镜对5种不同粒度的黄大茶粉进行观察,将适量样品放置于导电胶带上,使用离子溅射仪对样品进行喷金处理,将其置于扫描电子显微镜下观察样品形态。

1.2.7 面团热机械学特性的测定

将不同粒度的黄大茶粉分别按5%的比例与面粉充分混合备用,参考GB/T 37511-2009的方法,通过Mixolab2混合实验仪评估黄大茶粉对面团热机械性能的影响。采用Chopin+程序:每个样品在30 ℃条件下混合8 min后,以4 ℃/min的速度加热到90 ℃,再在90 ℃条件下保持7 min后,10 min内以4 ℃/min的速度冷却到50 ℃,最后在50 ℃下保持5 min。每个样品至少重复3次。

1.2.8 面团动态流变学的测定

将混合粉和去离子水以质量比5:3进行搅拌,3 min内搅成面团,随后将制作好的面团转移到流变仪平板上。使用直径40 mm的平板,温度为25 ℃,选取合适的应变值(0.1%)进行扫描,频率扫描范围是0.1~100 Hz。最终得到储能模量(G')、损耗模量(G'')和 tanδ随角频率变化的图谱。所有测试样品均在线性黏弹区。

1.2.9 面团糊化特性的测定

准确称取3 g分别添加不同粒度黄大茶粉的小麦粉(未添加黄大茶粉的小麦粉做空白对照),与25 mL去离子水混合均匀,用快速黏度分析仪(RVA)根据 AACC Approved Method 61-02(2000)对小麦粉糊化特性进行测定。

1.2.10 面团拉伸特性的测定

使用TA.XTPlus质构仪对面团的拉伸特性进行测定。测试前、中和后速度分别为:2 mm /s、3.3 mm/s和10 mm/s;拉伸距离:85 mm;触发力:5 g;数据采集速率:500 PPS。

1.3 数据处理

试验至少重复3次,结果用平均值±标准差形式表示,采用SPSS Statistics 17.0软件进行差异显著性分析,通过Microsoft Office Excel 2013与Origin 2019b进行图表分析和绘制。

2. 结果与分析

2.1 黄大茶粉添加量的确定

由表1可以看出,随着黄大茶粉添加量的增加,面团的硬度呈上升趋势,这可能是因为黄大茶粉中含有大量的膳食纤维,随着添加量的增加,膳食纤维越来越多,导致面团形成更加紧密的凝胶结构[15]。面团的弹性、内聚性和胶粘性主要是呈下降趋势。这是因为黄大茶粉的添加比例过高,导致面粉中蛋白质的含量降低,从而不利于面团中的蛋白质聚合作用,降低了面筋网络强度。由表中数据可知当黄大茶粉添加量为5%时,面团的弹性、内聚力和胶粘性与纯小麦面团没有显著性差异(P<0.05),同时硬度适中,故选择黄大茶粉的添加量为5%。

表 1 黄大茶粉添加量对面团质构的影响Table 1. Effects of the addition of yellow tea powder on dough texture添加量(%) 硬度(g) 弹性 内聚性 胶粘性 0 226.50±11.16e 0.45±0.03c 0.44±0.03c 167.64±9.12b 1 262.95±20.01e 0.64±0.03a 0.57±0.02a 226.91±5.12a 3 335.42±22.01d 0.54±0.02b 0.53±0.01b 176.14±11.22b 5 392.10±19.64c 0.44±0.03c 0.43±0.02c 165.91±5.22b 7 514.13±19.66b 0.38±0.01d 0.41±0.01c 145.25±4.32c 9 670.37±16.89a 0.33±0.01e 0.37±0.01d 117.80±3.16d 注:每组试验重复三次,同列中不同小写字母表示差异显著(P<0.05),表2~表4同。 2.2 不同粒度黄大茶粉的茶多酚、茶多糖含量

如图1所示,随着黄大茶粉的粒度不断减小,茶多酚和茶多糖含量主要呈上升趋势,当茶粉为超微Ⅲ时,上升速率降低。黄大茶粉碎后细胞壁和隔膜层遭到破坏,纤维素长链断裂,随着粒度的减小,接触面积增加,茶粉中茶多酚和茶多糖可浸提含量增多。可见,粒度减小有利于茶多酚和茶多糖的析出。

2.3 茶粉粒度扫描电镜检测

D(0.1)、D(0.5)、D(0.9)分别表示为10%、50%、90%的粉体小于或等于该值,D(4.3)表示粉体体积平均粒度。由扫描电镜图(图2)及表2可以直观看到,粗粉和细粉的颗粒较大,较大纤维颗粒,且分布不均匀。此时粗粉和细粉的体积平均粒度分别为263.97±8.76 µm、116.19±2.08 µm。超微粉粒度小于粗粉和细粉,均匀度大于粗粉和细粉,且随着超微时间的增加,粉体的粒度显著减小(P<0.05)。此时超微Ⅰ、超微Ⅱ、超微Ⅲ的体积平均粒度分别是108.26±1.92 µm、31.98±0.41 µm、14.93±0.62 µm。从图2可以直观看出均匀度有所增高,颗粒更加接近于球体。超微粉体有较小的聚集,造成这种现象的原因可能是黄大茶经过筛分和超微粉碎的过程中,茶粉与器械内壁、茶粉与茶粉之间相互碰撞摩擦,最终导致粉体颗粒带电,从而出现粉体聚集[16]。由此可得出,与粗粉和细粉相比,超微粉可以更好地实现黄茶的细胞级破碎,从而提升粉体的均匀度。

表 2 黄大茶粉粒度分布Table 2. Particle size distribution of Huangda tea powder类别 D(0.1)(µm) D(0.5)(µm) D(0.9)(µm) D(4.3)(µm) 粗粉 32.21±0.38a 199.21±3.00a 588.19±31.97a 263.97±8.76a 细粉 18.62±0.13b 104.21±2.00b 230.50±4.51b 116.19±2.08b 超微Ⅰ 10.06±0.09c 87.13±0.98c 242.45±5.97b 108.26±1.92c 超微Ⅱ 5.25±0.01d 25.31±0.15d 69.42±1.26c 31.98±0.41d 超微Ⅲ 4.65±0.05e 12.22±0.21e 27.58±0.83d 14.93±0.62e 2.4 含茶面团热机械学特性分析

粉质特性可以有效反映出面团的耐揉程度和后续产品加工性能。面制品的出品率与面团吸水率呈正相关。由表3可以看到,随着黄大茶粉粒度的减小,混合粉的吸水率逐渐增大,这与类似研究结果相一致[17−18]。这可能是由于粉体颗粒减小,接触面积增大,并且黄大茶粉中含有大量的纤维素以及多糖,与面筋蛋白和淀粉竞争水分,以氢键结合更多水,导致面团的吸水率的提高。也可能是因为膨胀的纤维将淀粉颗粒和蛋白质连接起来,在面条中形成连续的网络。类似研究表明,由于黄大茶粉中含有大量的羟基,例如茶多酚和茶多糖,可能导致混合粉的吸水率较高[19−20]。

表 3 不同粒度黄大茶粉对小麦粉质特性的影响Table 3. Effects of different grain sizes of yellow tea powder on wheat flour characteristics类别 吸水率(%) 形成时间(min) 稳定时间(min) 蛋白弱化度(Nm) 峰值粘度(Nm) 回生值(Nm) 空白 54.50±0.20e 3.51±0.44d 5.80±0.10e 0.51±0.01a 1.73±0.01a 0.85±0.06a 粗粉 55.00±0.10d 4.04±0.15cb 7.15±0.25d 0.51±0.03a 1.71±0.07a 0.74±0.01b 细粉 55.50±0.10c 4.11±0.12bc 8.60±0.10c 0.51±0.01a 1.73±0.03a 0.77±0.09b 超微Ⅰ 56.05±0.25b 4.44±0.24b 8.70±0.13c 0.47±0.01b 1.62±0.01c 0.76±0.02b 超微Ⅱ 56.90±0.10a 4.93±0.12a 8.40±0.10b 0.49±0.02ab 1.65±0.02bc 0.66±0.02c 超微Ⅲ 57.10±0.20a 5.05±0.13a 9.75±0.15a 0.49±0.01ab 1.71±0.02ab 0.68±0.06c 形成和稳定时间是衡量面粉筋力强度的重要指标。通常形成和稳定时间越长,面团越耐搅拌,筋力越强。混合面团的形成和稳定时间均显著高于小麦面团(P<0.05),可能是由于黄大茶粉与面团系统中的水和面筋蛋白相互作用,进而导致淀粉-面筋基质的中断和面团稳定性的增加。随着黄大茶粉粒度的减小,面团的形成时间和稳定时间显著增大(P<0.05)。这可能是由于茶粉粒度的减小,导致茶多酚溶出度增加,将面筋蛋白中的二硫键还原成自由疏基,麦谷蛋白分子间的聚合受到抑制,从而会破坏面筋的网络结构[21]。该结果表明,添加黄大茶粉后可以有延长面团网络结构的形成以及改良面团的筋力和韧性的效果。

蛋白质的崩解和变性与加热和过度搅拌有着很大的关系[22],蛋白质在热机械力作用下的弱化度值越小,说明面团面筋强度越大、面团机械稳定性越强,面团越不易流失,加工性能就越好[23]。当黄大茶粉为粗粉和细粉时,与对照组相比,弱化度未出现显著性差异,当黄大茶粉为超微粉时,面团的弱化度减小。随着黄大茶粉粒度的减小,面团中蛋白质的弱化度呈现下降趋势。该结果可能是由于黄大茶粉中蛋白质含量较高,且随着黄大茶粉颗粒的减小,其溶出度更好。同时,由于黄大茶粉的接触面积增大,从而会吸收更多的水分,进而使得面团稳定性提高。在加热和冷却循环过程中面团系统中的淀粉糊化特性可以用峰值粘度反应[24]。小麦面团中添加超微黄大茶粉后峰值粘度显著变化(P<0.05),当添加超微Ⅰ时峰值粘度最小。产生该结果的原因可能是淀粉颗粒结构被黄大茶粉破坏,造成淀粉进行部分降解,并且随着黄大茶粉粒度的减小,茶多酚和多糖等物质更容易溶出,导致其发生了变化。此外,在这个糊化过程中,形成的淀粉酶混合物以及析出的支链淀粉链均会对糊化产生影响,而且黄大茶粉中的某些物质会和淀粉竞争水分。

最终粘度和最低粘度之差被称为回生值,冷却阶段淀粉的稳定性可以通过回生值来进行反应,回生值越小,稳定性越大[25],并且和最终产品的保质期有关。本研究结果显示,与小麦面团对比,混合面团回生值显著下降(P<0.05),其中添加了超微Ⅱ的混合粉回生值最小,可见相同添加量下,添加超微Ⅱ的混合面团稳定性最好,更能抑制面团的回生。因为黄大茶粉中含有大量的酚类物质,可以抑制淀粉的老化。添加黄大茶粉可以改变面团的面筋强度。类似研究显示[26],绿茶粉、可溶性茶和茶多酚均能对面团的物理化学和结构性质产生影响,三种茶原料添加均能够提高面制品中的面筋强度。由表3可知,与小麦面团相比,黄大茶粉的加入会让面团的面筋含量降低,当添加的黄大茶粉为超微粉后,可以有效提高面团的筋力。

2.5 含茶面团动态流变学特性分析

小麦面团G'和G''的增加被认为与聚合物体系的交联强度有关。其中面筋通过肽羰基和酚羟基之间的氢键与多酚形成络合物,从而增强面团网络并改善面团的粘弹性[27]。由图5可以看出,对于所有样品,无论扫描频率如何变化,其损耗角正切值始终小于1,而面团样品的G'始终大于G''。这表明混合面团表现的是弹性行为而不是粘性行为[28]。同时,G'和G''值随着角频率的增加而增加(图3、图4)。该结果表明,在同等添加量的情况下,添加黄大茶粉可以提高面团的粘弹性,这是弱凝胶的典型动态流变曲线。因为在高频的情况下,面团恢复或者松弛的时间更少[29]。与小麦粉面团相比,混合面团的G'和G''明显提高。这说明黄大茶粉的添加能够增加面团的弹性,且能增强面筋强度。该结果可能是由于面团中的淀粉-麸质网络被黄大茶粉中含有的纤维素所影响所导致[30]。类似研究已证实葡萄籽粉粒度的增加可以增加面团的弹性和黏性,会对面包的品质产生影响[31]。

在固定角频率下,随着添加黄大茶粉的粒度的减小,G'和G''总体都呈现上升趋势,其中黄大茶粉超微Ⅰ和超微Ⅱ变化较为显著,这说明混合面团里分子间产生强烈的交联作用。正常情况下,麦谷蛋白和麦醇溶蛋白组成面筋蛋白,这两者都与面团的粘弹性有着很大的关系。其中醇溶蛋白与面团的黏性有关,而麦谷蛋白与面团的弹性有关。黄大茶粉中含有大量的茶多酚和单宁物质,该类物质可能会影响面团的粘弹性[32−33]。通常,单宁的添加能促进面筋蛋白之间的非共价相互作用和麸质蛋白的聚集,进而改变面筋网络的微观结构,改善混合性能[34]。由此可见,面筋蛋白逐渐吸收水分并膨胀,从而相互结合形成紧密的网络结构。同时,黄大茶中富含的纤维也会吸收水分并膨胀,进而与麸质蛋白片段缠绕交联,形成高弹性的麸质纤维混合物。类似报道显示,面筋蛋白和纤维成分两者同时作用并相互交叉结合,进而形成具有一定弹性、粘度和可塑性的三维网络结构[35−36]。

2.6 含茶面团热力学特性分析

糊化温度可以反应淀粉的结晶热稳定性,而淀粉熔融的双螺旋数目与糊化焓值相关[37],淀粉糊化可以被解释为吸水。在颗粒特定区域的膨胀和结晶秩序的丧失的过程中,面筋蛋白会由于糊化淀粉颗粒吸收水分从而失去弹性[38]。由表4可知,随着添加的黄大茶粉粒度的减小,混合粉的最终温度呈先下降后上升的趋势,但差异并不大。ΔH表示淀粉颗粒中支链淀粉糊化所需的能量。如表4所示,样品之间的ΔH从5.48 J/g明显下降到4.63 J/g,其中超微Ⅱ的面团最低。这可能是加热过程中淀粉颗粒的氢键会在分子内和分子间断裂,进而促进淀粉的糊化。较低的ΔH表明,淀粉颗粒的晶体结构更容易被破坏,得到无序的凝胶状态[39]。通常,茶制品中添加的茶叶成分可有效抑制淀粉回生,还可以降低面包的水分含量、硬度和吸热焓的损失[40]。此外,水作为一种增塑剂,也会对淀粉分子的迁移产生影响,进而影响到淀粉分子链间的聚合速率,尤其对淀粉的糊化和老化特性影响较大[41]。本研究中ΔH的减少,可能是由于添加黄大茶粉限制淀粉吸水性。而黄大茶粉在加热过程中能够插入淀粉分子内部,会影响颗粒结晶区域的双螺旋结构,进而削弱一些淀粉晶体的稳定性,最终导致ΔH值的降低[42]。

表 4 不同粒度黄大茶粉对面团热力学特性的影响Table 4. Effects of different grain sizes of yellow tea powder on thermodynamic characteristics of dough类别 T0(℃) TP(℃) TC(℃) ΔH(J/g) 空白 59.08±0.18ab 63.87±0.09a 68.19±0.54ab 5.48±0.16a 粗粉 58.80±0.27b 63.45±0.15bc 68.61±0.30a 5.47±0.14a 细粉 58.91±0.13b 63.37±0.15c 67.93±0.09ab 5.29±0.12ab 超微Ⅰ 58.99±0.40b 63.66±0.23ab 67.84±0.82abc 5.27±0.38ab 超微Ⅱ 59.57±0.59a 63.36±0.03c 67.11±0.35c 4.63±0.26c 超微Ⅲ 59.22±0.54ab 63.77±0.28a 67.79±0.87bc 4.87±0.59bc 2.7 含茶面团拉伸特性分析

面团拉伸性质通常是指将当外力作用在面团上所导致面团发生变形,而外力消失后面团所表现出来的弹性和可塑特性。面团的强度和筋力可以通过面团拉伸阻力来反映,拉伸的阻力越大,面团的筋力越强[43];面团的拉伸距离与面团的延展性和黏性有关[44],拉伸距离越大,面团的延展性越好。拉伸比是拉伸阻力和拉伸距离的比值,可以用来评判面团的烘焙品质和筋力强度。拉伸比越大,则拉伸距离越小,拉伸阻力越大。由图6可知,与空白组相比,混合粉的拉伸阻力显著上升(P<0.05),而随着黄大茶粉粒度的减小,混合粉的拉伸阻力先上升后下降,当茶粉为超微Ⅱ时拉伸阻力最大。由图7可知,空白组和混合粉的拉伸长度也有显著变化(P<0.05),呈先上升后下降的趋势,且超微Ⅲ的拉伸长度低于空白组。由图8可知,混合粉的拉伸比显著高于空白组(P<0.05),且随着粒度的减小呈现先上升后稳定的趋势。推测随着粒度的降低,其接触面积增大,纤维更有利于连接面团中的不同成分发挥作用,而粒度过小释放出来的纤维会破坏面团的稳定性。因此,选择合适的添加粒度尤为重要。

3. 结论

不同粒度的黄大茶粉添加到小麦粉中会在一定程度上对面团热机械学特性、流变特性、糊化特性以及拉伸特性产生影响。本研究显示,随着黄大茶粉粒度的减小,面团的吸水率呈上升趋势,弱化度呈下降趋势。添加黄大茶粉后,面团的形成和稳定时间有所提高,而糊化温度和糊化焓有所下降,但随着粒度的减小,混合面团的糊化温度上升,糊化焓下降。此外,混合面团的G'和G''明显提高,拉伸阻力和拉伸长度均呈现先上升后下降的趋势。尤其是超微Ⅱ的添加会大大改善面团的热机械学特性及流变特性。综上所述,本研究有望为黄大茶粉在含茶面制品中的广泛应用提供理论参考。然而,本研究主要以黄大茶为原料,其他茶类不同粒度茶粉的添加对面团特性的相关研究还值得深入探讨。

-

表 1 黄大茶粉添加量对面团质构的影响

Table 1 Effects of the addition of yellow tea powder on dough texture

添加量(%) 硬度(g) 弹性 内聚性 胶粘性 0 226.50±11.16e 0.45±0.03c 0.44±0.03c 167.64±9.12b 1 262.95±20.01e 0.64±0.03a 0.57±0.02a 226.91±5.12a 3 335.42±22.01d 0.54±0.02b 0.53±0.01b 176.14±11.22b 5 392.10±19.64c 0.44±0.03c 0.43±0.02c 165.91±5.22b 7 514.13±19.66b 0.38±0.01d 0.41±0.01c 145.25±4.32c 9 670.37±16.89a 0.33±0.01e 0.37±0.01d 117.80±3.16d 注:每组试验重复三次,同列中不同小写字母表示差异显著(P<0.05),表2~表4同。 表 2 黄大茶粉粒度分布

Table 2 Particle size distribution of Huangda tea powder

类别 D(0.1)(µm) D(0.5)(µm) D(0.9)(µm) D(4.3)(µm) 粗粉 32.21±0.38a 199.21±3.00a 588.19±31.97a 263.97±8.76a 细粉 18.62±0.13b 104.21±2.00b 230.50±4.51b 116.19±2.08b 超微Ⅰ 10.06±0.09c 87.13±0.98c 242.45±5.97b 108.26±1.92c 超微Ⅱ 5.25±0.01d 25.31±0.15d 69.42±1.26c 31.98±0.41d 超微Ⅲ 4.65±0.05e 12.22±0.21e 27.58±0.83d 14.93±0.62e 表 3 不同粒度黄大茶粉对小麦粉质特性的影响

Table 3 Effects of different grain sizes of yellow tea powder on wheat flour characteristics

类别 吸水率(%) 形成时间(min) 稳定时间(min) 蛋白弱化度(Nm) 峰值粘度(Nm) 回生值(Nm) 空白 54.50±0.20e 3.51±0.44d 5.80±0.10e 0.51±0.01a 1.73±0.01a 0.85±0.06a 粗粉 55.00±0.10d 4.04±0.15cb 7.15±0.25d 0.51±0.03a 1.71±0.07a 0.74±0.01b 细粉 55.50±0.10c 4.11±0.12bc 8.60±0.10c 0.51±0.01a 1.73±0.03a 0.77±0.09b 超微Ⅰ 56.05±0.25b 4.44±0.24b 8.70±0.13c 0.47±0.01b 1.62±0.01c 0.76±0.02b 超微Ⅱ 56.90±0.10a 4.93±0.12a 8.40±0.10b 0.49±0.02ab 1.65±0.02bc 0.66±0.02c 超微Ⅲ 57.10±0.20a 5.05±0.13a 9.75±0.15a 0.49±0.01ab 1.71±0.02ab 0.68±0.06c 表 4 不同粒度黄大茶粉对面团热力学特性的影响

Table 4 Effects of different grain sizes of yellow tea powder on thermodynamic characteristics of dough

类别 T0(℃) TP(℃) TC(℃) ΔH(J/g) 空白 59.08±0.18ab 63.87±0.09a 68.19±0.54ab 5.48±0.16a 粗粉 58.80±0.27b 63.45±0.15bc 68.61±0.30a 5.47±0.14a 细粉 58.91±0.13b 63.37±0.15c 67.93±0.09ab 5.29±0.12ab 超微Ⅰ 58.99±0.40b 63.66±0.23ab 67.84±0.82abc 5.27±0.38ab 超微Ⅱ 59.57±0.59a 63.36±0.03c 67.11±0.35c 4.63±0.26c 超微Ⅲ 59.22±0.54ab 63.77±0.28a 67.79±0.87bc 4.87±0.59bc -

[1] GUO X Y, HO C, SCHWAB W, et al. Aroma compositions of large-leaf yellow tea and potential effect of theanine on volatile formation in tea[J]. Food Chemistry,2019,280:73−82. doi: 10.1016/j.foodchem.2018.12.066

[2] SILVA F M R, MAGALHAES F E A, BATISTA F L A, et al. Microencapsulation of green tea (Camellia sinensis) phenolic extract:Physical-chemical characterization, antimicrobial and toxicological properties[J]. Food Chemistry Advances,2023,3:100360. doi: 10.1016/j.focha.2023.100360

[3] GUO X Y, HO C, SCHWAB W, et al. Effect of the roasting degree on flavor quality of large-leaf yellow tea[J]. Food Chemistry,2021,347:129016. doi: 10.1016/j.foodchem.2021.129016

[4] XU N, CHU J, WANG M, et al. Large yellow tea attenuates macrophage-related chronic inflammation and metabolic syndrome in high-fat diet treated mice[J]. Journal of Agricultural and Food Chemistry,2018,66(15):145−158.

[5] ZHAO G S, TENG J Y, DONG R X, et al. Alleviating effects and mechanisms of action of large-leaf yellow tea drinking on diabetes and diabetic nephropathy in mice[J]. Food Science and Human Wellness,2023,12(5):1660−1673. doi: 10.1016/j.fshw.2023.02.023

[6] 崔会娟, 郭兴凤. 面团流变学特性与面制品品质的关系[J]. 粮食加工,2015,40(2):28−31. [CUI Huijuan, GUO Xingfeng. Relationship between rheological properties of dough and quality of pasta products[J]. Grain Processing,2015,40(2):28−31.] CUI Huijuan, GUO Xingfeng. Relationship between rheological properties of dough and quality of pasta products[J]. Grain Processing, 2015, 40(2): 28−31.

[7] 汪名春, 钱秀丽, 夏传礼, 等. 黄秋葵全粉对小麦面团流变学特性的影响[J]. 食品工业科技,2022,43(22):122−128. [WANG Mingchun, QIAN Xiuli, XIA Chuanli, et al. Effects of whole okra flour on rheological properties of wheat dough[J]. Science and Technology of Food Industry,2022,43(22):122−128.] WANG Mingchun, QIAN Xiuli, XIA Chuanli, et al. Effects of whole okra flour on rheological properties of wheat dough[J]. Science and Technology of Food Industry, 2022, 43(22): 122−128.

[8] 梁靖, 刘学强, 邢芮蓁, 等. 食叶草粉对面团及面条品质特性的影响[J]. 食品工业科技:2023, 44:1−13. [LIANG Jing, LIU Xueqiang, XING Ruizhen, et al. Effects of leafy grass powder on the quality characteristics of dough and noodles[J]. Science and Technology of Food Industry, 2023, 44:1−13.] LIANG Jing, LIU Xueqiang, XING Ruizhen, et al. Effects of leafy grass powder on the quality characteristics of dough and noodles[J]. Science and Technology of Food Industry, 2023, 44: 1−13.

[9] 钱鑫, 李良怡, 周文化, 等. 银杏粉对小麦面团流变学特性和水分分布及迁移规律的影响[J]. 食品科学,2022,43(12):74−80. [QIAN Xin, LI Liangyi, ZHOU Wenhua, et al. Effects of ginkgo biloba powder on rheological properties and water distribution and migration patterns of wheat dough[J]. Food Science,2022,43(12):74−80.] doi: 10.7506/spkx1002-6630-20210507-065 QIAN Xin, LI Liangyi, ZHOU Wenhua, et al. Effects of ginkgo biloba powder on rheological properties and water distribution and migration patterns of wheat dough[J]. Food Science, 2022, 43(12): 74−80. doi: 10.7506/spkx1002-6630-20210507-065

[10] 张艳荣, 马宁鹤, 刘婷婷, 等. 香菇粉对干脆面面团流变特性及其油脂含量和分布的影响[J]. 食品科学,2020,41(10):47−52. [ZHANG Yanrong, MA Ninghe, LIU Tingting, et al. Effects of mushroom powder on the rheological properties of dry and crumbly pasta dough and its oil content and distribution[J]. Food Science,2020,41(10):47−52.] ZHANG Yanrong, MA Ninghe, LIU Tingting, et al. Effects of mushroom powder on the rheological properties of dry and crumbly pasta dough and its oil content and distribution[J]. Food Science, 2020, 41(10): 47−52.

[11] 冉隆贵, 高翔, 肖斌, 等. 茶叶粉对小麦面粉流变学及糊化特性的影响[J]. 麦类作物学报,2016,36(9):1234−1240. [RAN Longgui, GAO Xiang, XIAO Bin, et al. Effect of tea powder on rheological and pasting characteristics of wheat flour[J]. Journal of Wheat Crops,2016,36(9):1234−1240.] RAN Longgui, GAO Xiang, XIAO Bin, et al. Effect of tea powder on rheological and pasting characteristics of wheat flour[J]. Journal of Wheat Crops, 2016, 36(9): 1234−1240.

[12] 汪金萍, 曹蒙, 王雪菲, 等. 抹茶粉对面团流变学特性及面条品质的影响[J]. 现代食品科技,2022,38(8):229−235,115. [WANG Jinping, CAO Meng, WANG Xuefei, et al. Effects of matcha powder on rheological properties of dough and noodle quality[J]. Modern Food Science and Technology,2022,38(8):229−235,115.] WANG Jinping, CAO Meng, WANG Xuefei, et al. Effects of matcha powder on rheological properties of dough and noodle quality[J]. Modern Food Science and Technology, 2022, 38(8): 229−235,115.

[13] 冷进松, 朱珠, 王磊鑫, 等. 添加不同粒度紫苏粕对蒸烤馒头面团流变学特性的影响[J]. 食品工业,2016,37(12):17−21. [LENG Jinsong, ZHU Zhu, WANG Leixin, et al. Effects of adding different particle size perilla meal on the rheological properties of steamed bun dough[J]. Food Industry,2016,37(12):17−21.] LENG Jinsong, ZHU Zhu, WANG Leixin, et al. Effects of adding different particle size perilla meal on the rheological properties of steamed bun dough[J]. Food Industry, 2016, 37(12): 17−21.

[14] 王君荣, 曹佳兴, 刘翀, 等. 预处理不同粒度荞麦麸皮对面团及荞麦挂面品质的影响[J]. 食品研究与开发,2023,44(7):30−38. [WANG Junrong, CAO Jiaxing, LIU Chong, et al. Effects of pretreatment of buckwheat bran with different particle sizes on the quality of dough and buckwheat noodles[J]. Food Research and Development,2023,44(7):30−38.] WANG Junrong, CAO Jiaxing, LIU Chong, et al. Effects of pretreatment of buckwheat bran with different particle sizes on the quality of dough and buckwheat noodles[J]. Food Research and Development, 2023, 44(7): 30−38.

[15] 戴瑞, 杜密英, 付晶晶, 等. 桑叶粉添加量对生鲜面条品质及抗氧化活性的影响[J]. 现代食品科技,2023,39(12):226−233. [DAI Rui, DU Miying, FU Jingjing, et al. Effects of mulberry leaf powder addition on the quality and antioxidant activity of raw noodles[J]. Modern Food Science and Technology,2023,39(12):226−233.] DAI Rui, DU Miying, FU Jingjing, et al. Effects of mulberry leaf powder addition on the quality and antioxidant activity of raw noodles[J]. Modern Food Science and Technology, 2023, 39(12): 226−233.

[16] 牛希, 史乾坤, 赵城彬, 等. 超声改性对燕麦膳食纤维理化性质及结构的影响[J]. 食品科学,2020,41(23):130−136. [NIU Xi, SHI Qiankun, ZHAO Chengbin, et al. Effects of ultrasonic modification on the physicochemical properties and structure of oat dietary fiber[J]. Food Science,2020,41(23):130−136.] NIU Xi, SHI Qiankun, ZHAO Chengbin, et al. Effects of ultrasonic modification on the physicochemical properties and structure of oat dietary fiber[J]. Food Science, 2020, 41(23): 130−136.

[17] 鲍雨婷, 孙玥, 李雪玲, 等. 滁菊粉对面团特性和面包风味及其抗氧化活性的影响[J]. 食品科学, 2022:1−13. [BAO Yuting, SUN Yue, LI Xueling, et al. Effects of chu-chu powder on dough properties and bread flavor and its antioxidant activity[J]. Food Science, 2022:1−13.] BAO Yuting, SUN Yue, LI Xueling, et al. Effects of chu-chu powder on dough properties and bread flavor and its antioxidant activity[J]. Food Science, 2022: 1−13.

[18] BERNAERT N, DEBONNE E, De LEYN I, et al. Incorporation of leek powder (Allium ampeloprasum var. porrum) in wheat bread:Technological implications, shelf life and sensory evaluation[J]. LWT,2022,153:112517. doi: 10.1016/j.lwt.2021.112517

[19] ZHOU Y B, WANG D F, WAN X C, et al. Effect of tea polysaccharide addition on the properties of bread made from two flours[J]. Journal of Food Processing and Preservation.,2009,33(6):798−813. doi: 10.1111/j.1745-4549.2008.00312.x

[20] LI M, ZHANG J H, ZHU K X, et al. Effect of superfine green tea powder on the thermodynamic, rheological and fresh noodle making properties of wheat flour[J]. LWT - Food Science and Technology,2012,46(1):23−28. doi: 10.1016/j.lwt.2011.11.005

[21] 皮俊翔, 张根义. 茶多酚对面团中面筋蛋白结构的影响[J]. 食品工业科技,2020,41(18):1−7. [PI Junxiang, ZHANG Genyi. Effects of tea polyphenols on the structure of gluten proteins in dough[J]. Science and Technology of Food Industry,2020,41(18):1−7.] PI Junxiang, ZHANG Genyi. Effects of tea polyphenols on the structure of gluten proteins in dough[J]. Science and Technology of Food Industry, 2020, 41(18): 1−7.

[22] 段译霆. 亚麻籽粉添加对面团特性及挂面品质影响研究[D]. 咸阳:西北农林科技大学, 2022. [DUAN Yiting. Study on the effect of linseed flour on dough characteristics and quality of hanging noodles[D]. Xianyang:Northwest Agriculture and Forestry University, 2022.] DUAN Yiting. Study on the effect of linseed flour on dough characteristics and quality of hanging noodles[D]. Xianyang: Northwest Agriculture and Forestry University, 2022.

[23] 谭亦成, 陈丽, 张喻. 谷朊粉添加量对大米粉粉质特性影响研究[J]. 农产品加工(学刊),2014(21):13−15. [TAN Yicheng, CHEN Li, ZHANG Yu. Study on the effect of gluten addition on rice flour quality characteristics[J]. Agricultural Product Processing (Journal),2014(21):13−15.] TAN Yicheng, CHEN Li, ZHANG Yu. Study on the effect of gluten addition on rice flour quality characteristics[J]. Agricultural Product Processing (Journal), 2014(21): 13−15.

[24] DING J, HOU G G, NEMZER B V, et al. Effects of controlled germination on selected physicochemical and functional properties of whole-wheat flour and enhanced γ-aminobutyric acid accumulation by ultrasonication[J]. Food Chemistry,2018,243:214−221. doi: 10.1016/j.foodchem.2017.09.128

[25] 吕佳琪. 谷朊粉对五种杂粮面团特性和面条品质的影响[D]. 石家庄:河北经贸大学, 2021. [LÜ Jiaqi. Effects of gluten on dough characteristics and noodle quality of five kinds of mixed grains[D]. Shijiazhuang:Hebei University of Economics and Trade, 2021.] LÜ Jiaqi. Effects of gluten on dough characteristics and noodle quality of five kinds of mixed grains[D]. Shijiazhuang: Hebei University of Economics and Trade, 2021.

[26] HAN C W, MA M, ZHANG H H, et al. Progressive study of the effect of superfine green tea, soluble tea, and tea polyphenols on the physico-chemical and structural properties of wheat gluten in noodle system[J]. Food Chemistry,2020,308(C):64−75.

[27] HAN L H, ZHANG J J, CAO X H. Effects of orange peel powder on rheological properties of wheat dough and bread aging[J]. Food Science & Nutrition,2020,9(2):58−64.

[28] HAN T, PEI W, BARKAT A, et al. Fractionation and reconstitution experiments provide insight into the role of wheat starch in frozen dough[J]. Food Chemistry,2016,190:136−143.

[29] 朱香杰, 魏莹莹, 赵双丽, 等. 马铃薯蛋白微凝胶对无麸质面团流变特性和微观结构的影响[J]. 食品与发酵工业,2022,76:1−9. [ZHU Xiangjie, WEI Yingying, ZHAO Shuangli, et al. Effects of potato protein microgels on rheological properties and microstructure of gluten-free dough[J]. Food and Fermentation Industry,2022,76:1−9.] ZHU Xiangjie, WEI Yingying, ZHAO Shuangli, et al. Effects of potato protein microgels on rheological properties and microstructure of gluten-free dough[J]. Food and Fermentation Industry, 2022, 76: 1−9.

[30] ALINA C, GABRIELA M, DENISA E D. Rheological characterization of the dough with added dietary fiber by rheometer:A review[J]. Bulletin of University of Agricultural Sciences and Veterinary Medicine Cluj-Napoca Food Science and Technology,2020,77(1):87−94.

[31] VALKOVÁ V, ĎÚRANOVÁ H, ŠTEFÁNIKOVÁ J, et al. Wheat bread with grape seeds micropowder:Impact on dough rheology and bread properties[J]. 2020, 30(1):138−150.

[32] MENG Y C, SUN M H, SHENG F, et al. Effect of sucrose fatty acid esters on pasting, rheological properties and freeze–thaw stability of rice flour[J]. Food Hydrocolloids,2014,40:67−78.

[33] XU M, WU Y, HOU G G, et al. Evaluation of different tea extracts on dough, textural, and functional properties of dry Chinese white salted noodle[J]. LWT,2019,101:456−462. doi: 10.1016/j.lwt.2018.11.066

[34] QIONG W, YIN L, FUSHENG S, et al. Tannins improve dough mixing properties through affecting physicochemical and structural properties of wheat gluten proteins[J]. Food Research International,2015,69:115−123.

[35] YAO Z, TINGTING H, WENJIE Y, et al. Structural, thermal and rheological properties of gluten dough:Comparative changes by dextran, weak acidification and their combination[J]. Food Chemistry,2020,330(prepublish):36−47.

[36] HAN L H, ZHANG J J, CAO X H. Effects of orange peel powder on rheological properties of wheat dough and bread aging[J]. Food Science & Nutrition,2021,9(2):1061−1069.

[37] DING L, HUANG Q, LI H T, et al. Controlled gelatinization of potato parenchyma cells under excess water condition:structural and in vitro digestion properties of starch[J]. Food & Function,2019,10(9):123−139.

[38] 周童童. 马铃薯淀粉粒度对模拟面团特性的影响[D]. 北京:中国农业科学院, 2021. [ZHOU Tongtong. Effect of potato starch particle size on simulated dough properties[D]. Beijing:Chinese Academy of Agricultural Sciences, 2021.] ZHOU Tongtong. Effect of potato starch particle size on simulated dough properties[D]. Beijing: Chinese Academy of Agricultural Sciences, 2021.

[39] LIU D X, SONG S X, TAO L, et al. Effects of common buckwheat bran on wheat dough properties and noodle quality compared with common buckwheat hull[J]. LWT,2022,155:236−248.

[40] ZHOU Y B, WANG D F, ZHANG L, et al. Effect of polysaccharides on gelatinization and retrogradation of wheat starch[J]. Food Hydrocolloids,2007,22(4):341−357.

[41] 陈芳芳. 紫薯粉对面团烘焙特性的影响及其机理[D]. 上海:华东理工大学, 2014. [CHEN Fangfang. Effect of purple potato flour on dough baking characteristics and its mechanism[D]. Shanghai:East China University of Science and Technology, 2014.] CHEN Fangfang. Effect of purple potato flour on dough baking characteristics and its mechanism[D]. Shanghai: East China University of Science and Technology, 2014.

[42] ZENG J, GAO H, LI G L, et al. Effect of some oligosaccharides on functional properties of wheat starch[J]. Tropical Journal of Pharmaceutical Research,2015,14(1):167−178.

[43] 母梦羽, 张霞, 田郁, 等. 新收获不同筋力小麦后熟期间面团特性及微观结构变化[J]. 河南工业大学学报(自然科学版),2022,43(1):58−64. [MU Mengyu, ZHANG Xia, TIAN Yu, et al. Changes in dough characteristics and microstructure during post-ripening of newly harvested wheat with different gluten[J]. Journal of Henan University of Technology (Natural Science Edition),2022,43(1):58−64.] MU Mengyu, ZHANG Xia, TIAN Yu, et al. Changes in dough characteristics and microstructure during post-ripening of newly harvested wheat with different gluten[J]. Journal of Henan University of Technology (Natural Science Edition), 2022, 43(1): 58−64.

[44] WANG N F, GARY G H, ARNAUD D. Effects of flour particle size on the quality attributes of reconstituted whole-wheat flour and Chinese southern-type steamed bread[J]. LWT - Food Science and Technology,2017,82:257−264.

下载:

下载:

下载:

下载: