Characteristics Analysis of Different Glutinous Rice Flour and Its Influence on Freezing Point Temperature

-

摘要: 为明确不同糯米的粉质特性对冰点温度的影响,以实际应用中具有代表性的25种糯米粉为试验材料,测定其理化特性,通过相关性分析和主成分分析,探讨糯米粉原料特性对冰点温度的影响。结果表明,25种糯米粉粉团的冰点温度分布在−1.35~−2.65 ℃之间;脂肪含量与冰点温度成显著负相关(P<0.05),而蛋白质、淀粉、灰分与冰点温度之间不存在明显的依存关系;糯米粉热特性、吸水率、溶解度、胶稠度和平均粒径与冰点温度均呈极显著负相关(P<0.01)。主成分分析结果显示,影响糯米粉冰点温度的关键特性为糯米粉的平均粒径、热特性(峰值温度、起始温度、终止温度)、最终粘度、粗脂肪含量和溶解度。研究结果可为冰点冷冻汤圆工业化生产时合理选择糯米粉提供理论依据,实验范围内,优糯6211、黑糯米纯粉、预糊化糯米粉较为适合制作冰点冷冻汤圆。Abstract: In order to the main influence factors of glutinous rice farinographical properties on freezing point temperature, 25 representative glutinous rice flours in practical applications were used as test materials, and the physical and chemical properties of the glutinous rice flours were measured. Through correlation analysis and principal component analysis, the influence of the raw material characteristics of glutinous rice flour on the freezing point temperature was discussed. The results showed that the freezing point temperature of the 25 kinds of glutinous rice flour was between −1.35~−2.65 ℃. The fat content had a significant negative correlation with the freezing point temperature (P<0.05), while there was no obvious dependence between protein, starch, ash and freezing point temperature. The thermal properties, water absorption, solubility, gel consistency and average particle size of glutinous rice flour were all significantly negatively correlated with the freezing point temperature (P<0.01). Principal component analysis results showed that the key factors affecting the freezing point temperature of glutinous rice flour were mainly the average particle size of glutinous rice flour, the thermal characteristics of glutinous rice flour (peak temperature, starting temperature, ending temperature), final viscosity, crude fat content and solubility. The research results could provide a theoretical basis for the rational selection of raw materials for the industrial production of glutinous rice flour with freezing point frozen glutinous rice balls. Within the scope of the experiment, Younuo 6211, pure black glutinous rice flour, and pre-gelatinized glutinous rice flour are more suitable for making freezing point frozen tangyuan.

-

Keywords:

- glutinous rice flour /

- composition /

- physical and chemical index /

- freezing point

-

目前,城市化步伐的加快和人们消费习惯的改变,增加了消费者对方便食品的需求。汤圆是人们喜爱的传统糯米制品[1],虽已被消费者广泛接受,但速冻汤圆加工过程中仍存在诸多问题,例如:汤圆速冻后易出现塌陷、扁平、偏馅、漏馅、形状不规则、色泽灰暗、无光泽等,经过一段时间的冻藏后,还易出现不同程度的龟裂甚至开裂现象[2-4]。更需要注意的是,速冻食品冻结温度低、冻结时间长、贮藏温度较低,导致速冻食品生产和贮藏总体能耗较高。因此,有必要寻求一种既能保持速冻汤圆的优良品质又能节能降耗的新工艺来加工汤圆等面米制品。本团队前期研究结果表明(未发表),与速冻汤圆相比,冰点冷冻汤圆的整体品质与其差异不大,且由于冰点冷冻和冻结比传统汤圆冻结和贮藏温度均高很多,所以与传统速冻汤圆相比,冰点温度冻结的加工与贮藏过程中能耗降低,符合我国节能减排的政策措施要求,具有开发成为短保且节能减排的新型冻结食品的巨大潜力。

糯米粉是制作汤圆的主要原料之一。目前对于糯米粉的研究主要集中在糯米粉改良添加剂的研制[5-6]、复合糯米粉的调制等方面[7-8],以及不同品种糯米粉特性与速冻汤圆品质之间的关系等[9],而目前对于糯米粉冰点温度及其与理化指标相关性的研究还未见报道。

因此,本文从不同糯米粉原料特性出发,以25种糯米粉为试验材料,对它们的基本成分、理化指标、热特性、冰点温度等进行测定,并与冰点温度进行相关性分析和主成分分析,确定影响糯米粉冰点温度的关键指标,为后期冰点温度冻结和贮藏技术在汤圆中的应用及实际生产中冰点温度冻结汤圆原料的选择提供理论依据,也为传统冷冻食品寻找既能保持产品品质又可达到节能降耗效果的新技术奠定基础。

1. 材料与方法

1.1 材料与仪器

糯优2号、优糯6211、绍糯9714、血糯、嘉糯1优6号、皖垦糯、武育糯16号、苏御糯、丹旱稻53、连糯1号、南粳46 由河南农业大学农学院赵全志老师提供;东北粳糯、江西籼糯、安徽粳糯、信阳籼糯、浙江籼糯、2014越南籼糯、吉林粳糯、湖南水磨籼糯米粉、泰国水磨糯米粉、河北粳糯水磨粉、半干法黑糯米纯粉、黑糯米纯粉、半干法辊磨粳糯米、预糊化糯米粉 由河南黄国粮业股份有限公司提供;硼酸、硫酸、乙醚、硫代硫酸钠、氢氧化钠、硫酸钾 均为化学纯,国药集团化学试剂有限公司;碘化钾 化学纯,天津市科密欧化学试剂有限公司;乙醇 化学纯,天津市富宇精细化工有限公司;盐酸 优级纯,洛阳昊华化学试剂有限公司;硫酸铜 化学纯,天津市凯通化学试剂有限公司。

SZF-06A脂肪测定仪 乐清市精诚仪器仪表有限公司;KJELTEC 2300全自动凯氏定氮仪 丹麦福斯公司;Y410020破损淀粉测定仪 北京天翔飞域科技有限公司;RVA4500快速黏度分析仪 瑞典波通仪器公司;DSC 214 Polyma差示扫描量热仪 德国耐驰公司;Rise-2008激光粒度分析仪 济南润之科技有限公司。

1.2 实验方法

1.2.1 水磨糯米粉的制备

将水稻脱壳后清水洗涤,浸泡1 h,粉碎,胶体磨二次研磨制浆,4800 r/min离心10 min,弃去上清液,沉淀物45 ℃干燥24 h,研磨后过100目筛备用。

1.2.2 基本成分

糯米粉中水分、灰分、蛋白质、脂肪、淀粉等指标分别采用国标方法GB 5009.3-2016、GB 5009.4-2016、GB 5009.5-2016、GB 5009.6-2016、GB 5009.9-2016进行测定。

1.2.3 破损淀粉含量

使用损伤淀粉测定仪对糯米粉破损淀粉含量进行测定。在样品杯内加入3.0 g硼酸、3.0 g碘化钾、120 g蒸馏水,摇晃均匀,再加入1滴0.1 mol/L的硫代硫酸钠溶液,摇匀,将反应杯放进仪器卡槽内。称取1 g样品放入样品池中,开始测定,破损淀粉含量用碘吸收率(%)表示。

1.2.4 理化性质的测定

1.2.4.1 粒径

使用Rise-2008激光粒度分析仪对糯米粉粒径大小与分布进行检测。测验范围:0.01~3000 μm,使用仪器自带分析软件对数据进行分析。仪器会自动记录待测样品D50、Dav等数据[10]。

1.2.4.2 溶解度与吸水率

称取1 g(干基)糯米粉样品于已知质量P1的离心管中,加水定容至50 mL,25 ℃水浴锅振荡30 min,4800 r/min离心15 min,上清液倒入已恒重的铝盒内,105 ℃烘干至恒重,得到溶解的粉的质量A。称取此时离心管质量P2,根据公式确定糯米粉的溶解度和吸水率[11]。

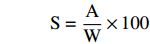

S=AW×100 B=P2−P1W(100−S)×100 式中:S表示溶解度,%;B表示吸水率,%;A表示滤液烘干恒重后的质量,g;W表示样品干基质量,g。

1.2.4.3 胶稠度

胶稠度按照 GB /T 22294 -2008 进行测定。

1.2.4.4 膨胀能力

精确称量0.25 g糯米粉样品(干基)于烧杯内,倒入25 mL蒸馏水并不停搅拌,95 ℃水浴锅中加热30 min后将淀粉溶液迅速倒入25 mL量筒中,室温下放置24 h,读出糯米粉粒在量筒中沉降的体积[12],每克糯米粉的沉降颗粒所占的体积即为膨胀能力,即:

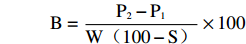

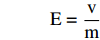

E=vm 式中:E表示膨胀能力,mL/g;v表示沉降颗粒所占的体积,mL;m表示样品质量,g。

1.2.5 糊化特性

使用快速粘度分析仪进行糯米粉糊化特性测定[13],准确称取(2.50±0.01)g糯米粉样品和(25.0±0.2)mL蒸馏水于特制铝盒内,充分搅拌后,置于RVA样品槽内,开始测试。测试程序如下:初始搅拌速率1000 r/min,时间5 s,使溶液充分搅拌均匀,起始温度50 ℃,以12 ℃/min由50 ℃上升至95 ℃,并恒温5 min,以同样的速率由95 ℃下降至50 ℃,全过程总计13 min,测试结束。

1.2.6 冰点温度

采用差示扫描量热仪法测定糯米粉冰点温度,参考钟志友等[14]的方法稍有改进。称取一定量的糯米粉于10 mL离心管中,按照粉体:水=1:3的体积向离心管中加入蒸馏水,使用涡旋振荡器振荡15 s使溶液混匀,使用移液枪精确吸取10 mg糯米粉溶液于特制的铝制坩埚中,用专用的压盖器将坩埚压盖紧,置于差示扫描量热仪炉体内,同时放入空白坩埚作为对照,温度程序设置:以5.0 ℃/min 速率降温至−30.0 ℃;保持温度5.0 min;以5.0 ℃/min的速率升温至25 ℃,紧急复位温度为30 ℃,停止记录数据,取升温曲线峰值相变起始温度(即将结晶刚刚开始熔化的温度)定为冰点温度。

1.2.7 热力学特性

样品制备与1.2.6相同。空白坩埚作为对照,设置扫描温度为25~135 ℃,升温速率为10 ℃/min,根据DSC特性曲线分析峰的特征,进行热焓值(ΔH)测定[15-16]。

1.3 数据分析

每组试验均重复3次,结果用

¯X ±SD表示。采用SPSS 23软件进行主成分分析(P<0.05代表显著性差异,P<0.01代表极显著差异)。2. 结果与分析

2.1 不同糯米粉基本成分分析

如表1所示,整体来看,经过机器脱壳研磨过的糯米粉灰分含量集中在0.16%~1.22%,蛋白质含量分布在5.38%~9.15%之间,淀粉含量主要在83.31%~91.65%之间,脂肪含量为0.59%~3.18%。蛋白质含量最高可达9.15%(皖垦糯、丹旱稻53);脂肪含量相对较低,大部分集中在1%左右,除血糯、半干法黑糯米纯粉、黑糯米纯粉以外其余糯米粉品种脂肪含量均不超过2%,灰分含量所占比例最低,基本不超过1%。由表1可知,25种糯米粉的破损淀粉含量分布在3.52%~6.51%区间。糯优2号、绍糯9714、连糯1号、预糊化糯米粉这4种糯米粉的破损淀粉含量较低,均不到4%,由这几种粉揉制而成的粉团加工特性会更好。而武育糯16号、苏御糯、信阳籼糯、湖南水磨籼糯米粉、泰国水磨糯米粉、河北粳糯水磨粉的破损淀粉含量较高,超出6%。Lin等[17]通过分析破损淀粉对糯米粉性能和汤圆品质的影响发现,随着破损淀粉含量的增高,糯米粉制得的汤圆切面结构变得松散,水分流动性增强。因此,在糯米粉加工过程中,应当对糯米加工方法、研磨强度、温度、含水量等工艺参数进行优选,保护淀粉颗粒的完整性,降低破损淀粉含量,最终获得品质优质的糯米粉。

表 1 不同糯米粉基本成分分析Table 1. Analysis of the basic components of different glutinous rice flour样品 水分(%) 灰分(%) 淀粉(%) 破损淀粉(%) 蛋白质(%) 脂肪(%) 糯优2号 11.2±0.11h 0.23±0.01m 86.49±0.37i 3.52±0.01u 5.89±0.08o 0.71±0.01lm 优糯6211 9.70±0.15l 0.16±0.00o 90.40±0.11cd 4.24±0.03p 5.62±0.06p 0.61±0.03n 绍糯9714 10.50±0.14j 0.21±0.01n 86.30±0.45i 3.82±0.05t 8.44±0.04c 1.22±0.01g 血糯 10.10±0.13k 0.23±0.01m 90.85±0.11bc 5.22±0.01m 6.54±0.06lm 2.65±0.05b 嘉糯1优6号 10.30±0.15jk 0.33±0.01i 91.13±0.13ab 5.62±0.01j 8.23±0.05d 1.05±0.04h 皖垦糯 8.60±0.20n 0.23±0.00m 88.29±0.11g 5.76±0.04g 9.15±0.06a 0.84±0.01k 武育糯16号 11.50±0.42efg 0.17±0.01o 85.15±0.17jk 6.20±0.01c 8.73±0.06b 0.76±0.02l 苏御糯 11.30±0.10gh 0.53±0.01e 83.46±0.41m 6.06±0.03e 7.48±0.04g 0.68±0.01m 丹旱稻53 10.30±0.21jk 0.17±0.01o 91.49±0.31a 4.91±0.04n 9.15±0.08a 0.73±0.06lm 连糯1号 9.50±0.09l 0.26±0.01l 86.59±0.21i 3.84±0.08t 7.24±0.06hi 0.60±0.01n 南粳46 9.20±0.08m 0.38±0.01g 90.12±0.37de 5.36±0.04l 5.38±0.06q 0.82±0.05k 东北粳糯 11.60±0.01ef 0.43±0.01f 91.65±0.20a 4.94±0.01n 6.20±0.03n 0.84±0.01k 江西籼糯 11.20±0.02h 0.23±0.01m 88.88±0.19f 5.74±0.02gh 6.44±0.03m 0.98±0.02i 安徽粳糯 10.50±0.01j 0.31±0.01j 86.62±0.66i 5.65±0.03ij 6.57±0.08l 1.76±0.03d 信阳籼糯 10.90±0.01i 0.56±0.01d 87.40±0.17h 6.10±0.03de 6.74±0.11k 0.84±0.02k 浙江籼糯 11.40±0.01fgh 0.36±0.00h 83.31±0.31n 5.85±0.05f 7.74±0.02e 0.59±0.04n 2014越南籼糯 12.40±0.02b 0.26±0.01l 84.77±0.31kl 4.53±0.02o 7.61±0.04f 0.76±0.01l 吉林粳糯 12.10±0.03c 0.28±0.01k 91.49±0.13a 5.46±0.01k 7.01±0.10j 1.27±0.08g 湖南水磨籼糯米粉 11.90±0.01cd 0.29±0.01k 88.40±0.07fg 6.34±0.01b 7.17±0.06i 0.74±0.03lm 泰国水磨糯米粉 12.60±0.01b 0.28±0.01k 85.47±0.10j 6.51±0.02a 7.32±0.09h 1.54±0.06e 河北粳糯水磨粉 12.90±0.02a 0.58±0.01c 91.24±0.60ab 6.13±0.03d 5.99±0.13o 1.33±0.01f 半干法黑糯米纯粉 11.70±0.03de 1.14±0.01b 89.54±0.54e 4.04±0.01r 8.67±0.06b 2.07±0.03c 黑糯米纯粉 10.30±0.05jk 1.22±0.02a 89.76±0.11e 4.10±0.01q 8.22±0.04d 3.18±0.05a 半干法辊磨粳糯米 11.60±0.08ef 0.34±0.01i 89.94±0.38de 5.69±0.04hi 8.27±0.05d 0.92±0.01j 预糊化糯米粉 7.80±0.08o 0.22±0.01mn 84.56±0.28lm 3.92±0.01s 5.65±0.10p 1.72±0.02d 注:表中基本成分(除水分)的数据均为干基;同列不同小写字母表示差异显著(P<0.05),表2~表4同。 2.2 不同糯米粉理化性质分析

(D90-D10)/D50代表了糯米粉粒径的分布宽窄度,数值越小,说明糯米粉的颗粒体积较集中。由表2可知,湖南水磨籼糯米粉、2014越南籼糯、半干法辊磨粳糯米的粒径分布较窄,颗粒体积大小较集中,安徽粳糯、东北粳糯、苏御糯的颗粒体积大小分布相对较散。本试验范围内选用的糯米粉平均粒径数值主要分为两大类,一类糯米粉的平均粒径较小,主要集中在6.59~23.53 μm之间,另一类糯米粉平均粒径较大,主要分布在38.61~88.05 μm之间。血糯的平均粒径最小为6.59 μm,而预糊化糯米粉平均粒径最大为88.05 μm,制备工艺不同导致了不同品种糯米粉的平均粒径不同。

表 2 糯米粉的理化性质Table 2. The physicochemical properties of glutinous rice flour样品 (D90-D10)/D50 Dav(μm) 吸水率(%) 溶解度(%) 胶稠度(mm) 膨胀能力(mL·g−1) 糯优2号 1.58±0.01c 6.87±0.57q 2.24±0.01efghij 0.77±0.03i 142.20±0.48i 4.30±0.21t 优糯6211 1.46±0.01f 7.47±0.04p 2.15±0.03ghijk 1.25±0.02e 162.20±0.27c 3.90±0.19t 绍糯9714 1.57±0.02c 8.56±0.02mn 2.15±0.01ghijk 1.15±0.01f 109.00±0.11p 7.70±0.17r 血糯 1.69±0.03b 6.59±0.06q 2.26±0.02efghi 0.51±0.04m 129.40±0.61l 35.70±0.21a 嘉糯1优6号 1.43±0.01f 8.26±0.03n 2.21±0.02fghij 0.68±0.01j 155.50±0.33e 17.30±0.46m 皖垦糯 1.43±0.01f 7.77±0.01op 2.08±0.01jkl 0.55±0.00kl 116.40±0.20n 32.70±0.29d 武育糯16号 1.57±0.05c 7.92±0.11o 2.14±0.02hijk 0.27±0.02p 155.40±0.52e 34.00±0.18c 苏御糯 1.66±0.11b 9.60±0.12l 1.95±0.01l 0.38±0.01no 85.00±0.49r 12.30±0.50o 丹旱稻53 1.45±0.02f 8.86±0.03m 2.09±0.01ijkl 0.41±0.00n 115.10±0.60o 4.90±0.050s 连糯1号 1.52±0.03de 7.79±0.07op 2.22±0.02efghij 0.25±0.02p 146.00±0.45g 35.20±0.30b 南粳46 1.50±0.00e 8.26±0.03n 2.00±0.01kl 0.41±0.01n 72.90±0.50s 11.70±0.20p 东北粳糯 1.70±0.01b 6.62±0.02q 2.34±0.01def 0.87±0.02h 108.60±0.38p 9.90±0.18q 江西籼糯 1.28±0.01g 7.54±0.01p 2.07±0.01jkl 0.52±0.04lm 119.30±0.11m 19.90±0.06j 安徽粳糯 1.82±0.02a 10.53±0.19k 2.15±0.02ghijk 0.56±0.01k 132.70±0.16k 35.50±0.04ab 信阳籼糯 1.55±0.05cd 8.44±0.27n 2.27±0.00efgh 0.85±0.02h 143.80±0.06h 20.40±0.22i 浙江籼糯 1.29±0.06g 60.47±0.14c 2.44±0.01d 1.07±0.01g 155.60±0.29e 25.10±0.47g 2014越南籼糯 0.80±0.01k 45.79±0.06f 2.35±0.00def 1.65±0.00c 154.90±0.24e 27.70±0.04f 吉林粳糯 1.12±0.02h 55.46±0.42e 2.16±0.01ghijk 0.37±0.02o 142.80±0.26i 13.90±0.02n 湖南水磨籼糯米粉 0.86±0.00j 39.13±0.02g 2.22±0.04efghij 0.40±0.01no 162.10±0.30c 19.10±0.17k 泰国水磨糯米粉 0.92±0.02i 38.61±0.04h 2.38±0.01de 0.67±0.01j 151.40±0.45f 28.40±0.31e 河北粳糯水磨粉 1.15±0.01h 57.67±0.22d 2.32±0.01defg 0.53±0.04klm 170.00±0.78a 25.50±0.21g 半干法黑糯米纯粉 1.12±0.00h 21.61±0.03j 3.01±0.04b 1.67±0.03c 134.30±0.16j 7.80±0.11r 黑糯米纯粉 1.42±0.02f 23.53±0.20i 2.43±0.03d 2.17±0.01b 160.00±0.62d 9.70±0.15q 半干法辊磨粳糯米 0.89±0.01ij 78.11±0.28b 2.60±0.01c 1.53±0.01d 89.40±0.45q 18.30±0.45l 预糊化糯米粉 1.30±0.01g 88.05±0.22a 6.86±0.43a 2.26±0.02a 165.20±0.45b 21.50±0.11h 由表2可知,糯米粉的胶稠度分布较分散,河北粳糯水磨粉胶稠度达到170.00 mm,优糯6211的胶稠度达162.20 mm,而南粳46、苏御糯、半干法辊磨粳糯米的胶稠度较低,仅有72.90、85.00、89.40 mm;不同品种糯米粉的膨胀能力数值相差较大,糯优2号、优糯6211、丹旱稻53的膨胀度分别为4.30、3.90、4.90 mL·g−1,而血糯、皖垦糯、武育糯16号、连糯1号、安徽粳糯的膨胀度较大,均达到30.00 mL·g−1以上。不同糯米粉溶解度差异较大,预糊化糯米粉、黑糯米纯粉达到2%以上,而武育糯16号、连糯1号溶解度在0.25%左右。吸水率方面只有预糊化糯米粉较大,达到6%以上,其余品种糯米粉吸水率较集中在2%左右。主要可能是和预糊化糯米粉水分含量最低有关(仅7.80%),宋莹莹[18]通过相关性分析表明,糯米粉的吸水率与初始水分含量呈负相关。

2.3 糊化特性

由表3可知,泰国水磨糯米粉具有最大的峰值粘度为4019 mP·s,而丹旱稻53与黑糯米纯粉峰值粘度最低分别为576.5与573 mP·s,可能与泰国水磨糯米粉具有较大膨胀程度(其膨胀能力为28.40 mL·g−1),而丹旱稻53与黑糯米纯粉膨胀度较小有关,它们的膨胀能力分别为4.90和9.70 mL·g−1,但此两种糯米粉衰减值最小,分别为313.00、398.00 mP·s,说明其在热膨胀的过程中可以承受较大压力,不易破裂,具有更高强度,热糊稳定性好[19],而预糊化糯米粉稳定性最差。半干法黑糯米纯粉的回生值最大,达到了1176.00 mP·s,其次是苏御糯回生值为463.50 mP·s,说明两种粉稳定性最好,不易老化,而黑糯米纯粉回生值只有76.5 mP·s,说明其最容易老化,稳定性差。

表 3 糯米粉糊化特性分析Table 3. The pasting characteristics of the glutinous rice flour样品 峰值粘度(mP·s) 谷值粘度(mP·s) 衰减值(mP·s) 最终粘度(mP·s) 回生值(mP·s) 糊化温度(℃) 糯优2号 1242.00±2.80h 572.00±1.40p 670.00±1.40hijk 741.00±5.70o 169.00±4.20k 80.40±0.60b 优糯6211 1449.00±9.90gh 768.00±0.00m 681.00±9.90hijk 952.00±4.20l 184.00±4.20j 83.23±0.10b 绍糯9714 616.00±7.10i 205.50±3.50r 410.50±3.50jk 297.00±4.20q 91.50±0.70m 71.88±0.00cde 血糯 1657.50±6.40efg 666.00±0.00o 991.50±6.40efghi 836.00±2.80n 170.00±2.80k 69.83±0.60def 嘉糯1优6号 1255.00±18.40h 570.50±14.80p 684.50±3.50hijk 756.50±19.10o 186.00±4.20j 80.40±0.60b 皖垦糯 1887.00±1.40def 965.00±7.10ij 922.00±5.70fghi 1270.50±4.90h 305.50±2.10d 72.68±0.00cde 武育糯16号 2198.50±6.40d 1016.50±0.70gh 1182.00±7.10defg 1250.50±3.50h 234.00±4.20gh 69.85±0.60def 苏御糯 2143.00±25.50d 1335.00±1.40e 808.00±240ghij 1798.50±3.50e 463.50±2.10b 72.60±0.00cde 丹旱稻53 576.50±4.90i 263.50±0.70q 313.00±5.70k 366.50±2.10p 103.00±1.40l 73.10±0.60cd 连糯1号 1844.00±19.80defg 856.00±4.20l 988.00±24.00efghi 1092.00±4.20k 236.00±0.00gh 70.25±0.00def 南粳46 1573.50±0.70fgh 855.00±33.90l 718.50±33.20hijk 1243.00±32.50h 388.00±1.40c 73.50±1.30cd 东北粳糯 2238.00±1.40d 948.50±0.70jk 1289.50±2.10def 1133.50±7.80j 185.00±7.10j 68.25±0.50ef 江西籼糯 1719.00±9.90efg 1000.00±0.00h 719.00±9.90hijk 1256.00±9.90h 256.00±9.90f 73.55±0.00cd 安徽粳糯 1713.00±5.70efg 715.00±7.10n 998.00±12.70efghi 912.50±2.10m 197.50±4.90i 69.90±0.70def 信阳籼糯 1693.50±26.20efg 1108.00±15.60f 585.50±10.60ijk 1346.50±7.80g 238.50±7.80gh 81.18±0.50b 浙江籼糯 3458.00±8.50b 1651.00±4.20c 1807.00±4.20b 1880.50±3.50d 229.50±0.70h 69.45±0.10def 2014越南籼糯 3233.00±0.00b 1811.00±5.70b 1422.00±5.70cd 2083.50±7.80c 272.50±2.10e 70.63±0.50def 吉林粳糯 1649.50±4.90efg 922.00±7.10k 727.50±12.00hijk 1127.00±12.70j 205.00±5.70i 72.28±0.70cde 湖南水磨籼糯米粉 2215.50±19.10d 986.00±2.80hi 1229.50±16.30def 1242.50±4.90h 256.50±7.80f 71.85±1.10cde 泰国水磨糯米粉 4019.00±28.30a 2302.50±2.10a 1716.50±26.20bc 2606.50±9.20a 304.00±7.10d 70.18±0.00def 河北粳糯水磨粉 2723.50±6.40c 1369.00±0.00d 1354.50±6.40cde 1612.50±3.50f 243.50±3.50g 66.075±0.00f 半干法黑糯米纯粉 1624.00±15.60efgh 1037.00±56.60g 587.00±41.00ijk 2213.00±55.20b 1176.00±1.40a 91.70±0.60a 黑糯米纯粉 573.00±7.10i 175.00±2.80s 398.00±4.20jk 251.50±3.50r 76.50±0.70n 71.025±0.00de 半干法辊磨粳糯米 2001.50±9.20de 933.50±6.40k 1068.00±2.80defgh 1208.50±3.50i 275.00±9.90e 68.10±0.60ef 预糊化糯米粉 3096.50±862.00b 565.00±5.70p 2531.50±867.60a 848.00±7.10n 283.00±1.40e 75.75±9.20c 2.4 糯米粉冰点温度与热特性分析

由图1、表4可知,不同品种糯米粉的冰点温度范围在−1.35~−2.65 ℃之间,由于糯米粉品种不同,淀粉颗粒大小、形成的空间网状结构不同,内部水分结晶的快慢亦不同,所以冰点温度有细微差别。预糊化糯米粉的冰点温度最低(−2.65 ℃),其次是优糯6211和黑糯米纯粉的冰点温度,均在−2.55 ℃。不同品种糯米粉的糊化起始温度大多集中于60.00~70.00 ℃之间,优糯6211和信阳籼糯起始糊化温度最高分别为74.60和74.55 ℃。峰值温度则集中在65.00~ 80.00 ℃ 之间,半干法辊磨粳糯米峰值温度最高为81.25 ℃。糊化焓ΔH大部分集中在1.00~3.00 J/g之间,最低的泰国水磨糯米粉只有0.78 J/g,糊化焓值最大的糯米粉为糯优2号,达到3.35 J/g。糯米粉中含有大量淀粉,而淀粉类食品的烹饪加工基本都是在高温条件下进行,测定糯米粉热特性尤其是对峰值温度、焓值的测定,有助于为食品的品质提升提供依据[20-21]。有研究[22-23]指出淀粉颗粒结构、淀粉-淀粉间的结构会影响到起始温度、峰值温度及终点温度,而直链淀粉含量则会影响糊化焓变[24]。

表 4 糯米粉的冰点与热特性测定Table 4. The freezing point and thermal properties of glutinous rice flour样品 冰点温度(℃) 起始温度(℃) 峰值温度(℃) 终止温度(℃) 糊化焓ΔH(J·g−1) 糯优2号 −2.10±0.00hij 74.40±0.28a 78.15±0.07c 83.75±0.21c 3.35±0.00a 优糯6211 −2.55±0.07l 74.60±0.14a 78.55±0.35c 82.65±0.64d 3.12±0.07b 绍糯9714 −1.75±0.07ef 60.25±0.07fg 68.45±0.07fg 73.65±0.21kl 1.94±0.07j 血糯 −1.85±0.07fg 65.00±0.28cd 66.75±0.35hi 72.80±0.28lmn 1.69±0.00l 嘉糯1优6号 −2.05±0.07hij 74.05±0.49a 78.35±0.64c 81.45±0.64e 1.52±0.02m 皖垦糯 −2.30±0.00k 64.90±0.42d 70.56±0.08de 75.90±0.85fgh 2.07±0.08i 武育糯16号 −2.20±0.14jk 63.30±0.57e 68.35±0.64fg 72.75±0.49lmn 1.81±0.02k 苏御糯 −1.50±0.14bc 59.90±0.14fg 65.95±0.64i 72.65±0.35mn 1.72±0.00l 丹旱稻53 −1.35±0.07a 64.60±0.85d 70.35±0.64de 75.25±0.35hi 2.63±0.01c 连糯1号 −1.97±0.06gh 62.80±0.42e 68.20±0.99fg 73.30±0.57klm 2.41±0.02e 南粳46 −1.68±0.05de 60.75±0.35f 67.35±0.21gh 72.55±0.64mn 2.21±0.10gh 东北粳糯 −1.40±0.14ab 59.60±0.57g 66.90±0.42hi 72.45±0.49mn 2.14±0.02hi 江西籼糯 −2.05±0.07hij 65.70±0.42c 71.30±0.28d 76.25±0.07fg 1.53±0.07m 安徽粳糯 −1.55±0.07cd 59.45±0.78g 65.75±0.78ij 72.80±0.28lmn 2.32±0.08f 信阳籼糯 −2.10±0.14hij 74.55±0.64a 80.00±0.99b 84.95±0.49b 2.37±0.05ef 浙江籼糯 −1.60±0.14cde 59.80±0.85fg 66.90±0.28hi 72.00±0.85n 2.50±0.09d 2014越南籼糯 −2.00±0.00ghi 62.40±0.28e 68.70±0.28f 74.60±0.28ij 2.24±0.03g 吉林粳糯 −2.05±0.07hij 62.65±0.21e 70.40±0.28de 76.45±0.35f 2.18±0.03gh 湖南水磨籼糯米粉 −2.05±0.07hij 64.50±0.85d 70.15±0.64de 75.35±0.78ghi 2.50±0.01d 泰国水磨糯米粉 −1.65±0.07cde 62.90±1.27e 69.90±0.99e 73.90±0.42jk 0.78±0.00p 河北粳糯水磨粉 −2.15±0.07ijk 54.35±0.78h 64.10±0.85k 69.30±0.57o 1.93±0.06j 半干法黑糯米纯粉 −1.85±0.07fg 60.50±0.42fg 64.70±1.70jk 68.95±0.21o 0.98±0.01o 黑糯米纯粉 −2.55±0.07l 62.40±0.42e 68.65±0.64f 75.55±0.49fgh 1.41±0.02n 半干法辊磨粳糯米 −2.15±0.07ijk 72.35±0.64b 81.25±0.21a 86.10±0.85a 1.35±0.02n 预糊化糯米粉 −2.65±0.07l 72.65±0.78b 77.80±0.85c 84.30±0.57bc 1.96±0.02j 2.5 冰点温度与指标的相关性分析

由表5可知,脂肪含量与冰点温度呈显著负相关(r=−0.30,P<0.05),即脂肪含量越高,冰点温度越低。这可能是由于脂肪中含有磷酸基团,可以与淀粉中的酯类物质相结合形成磷酸基复合物,而这些复合物可以促进淀粉颗粒吸水溶胀,使得细胞内水分较多,冻结结晶速度较慢,冰点也就越低[25]。也可能是由于脂肪与直链淀粉相结合形成聚合物,使得颗粒周围半固形区加速水解,水分可以更快进入淀粉颗粒内部,使得淀粉颗粒间自由水含量降低,从而导致结冰困难,从而冰点较低[26-27]。

表 5 糯米粉冰点温度与理化性质的相关性分析Table 5. Correlation analysis between the freezing point and physicochemical properties of glutinous rice flour指标 冰点温度 指标 冰点温度 蛋白质 0.12 膨胀能力 0.01 灰分 −0.11 胶稠度 −0.44** 脂肪 −0.30* 峰值粘度 0.05 淀粉 0.09 谷值粘度 0.22 峰值温度 −0.50** 衰减值 −0.12 起始温度 −0.52** 最终粘度 0.21 终止温度 −0.51** 回生值 0.08 糊化焓 −0.01 糊化温度 −0.25 吸水率 −0.41** Dav −0.31** 溶解度 −0.50** 注:**表示在0.01水平上极显著相关;*表示在0.05水平上显著相关。 吸水率、溶解度与冰点温度呈极显著负相关(r=−0.41、r=−0.50,P<0.01),即吸水率、溶解度越大,冰点温度越低。吸水率与溶解度大的糯米粉品种,其内部淀粉分子结晶区域的氢键通常较弱,晶体结构易被破坏,外部游离水进入分子,吸水率变大,溶解度高,进入分子内部的水分越多,分子间自由水就越少,结冰也就越困难,从而导致冰点温度降低[16]。有研究[28-29]指出胶稠度与直链淀粉数量有关,且呈极显著负相关,当胶稠度越大时,直链淀粉数量较少。而由表5得知,胶稠度与冰点温度呈极显著负相关(r=−0.44,P<0.01),即糯米粉胶稠度越大,冰点温度越低,这可能是由于糯米粉中的直链淀粉数量较少,支链淀粉含量较多,所形成的空间网状结构较疏松,水分流动受到的阻力较小流动较快,冻结成冰晶的速度较久,冰点温度较低。糯米粉平均粒径与冰点温度呈极显著负相关(r=−0.31,P<0.01),即糯米粉颗粒粒径越大,则冰点温度越低。曹松等[30]研究表明由于磨粉过程中粒度较大的淀粉颗粒比粒度小的淀粉颗粒有更好的保水性。而保水性强,抗冻性也是相对来说比较好,因此糯米粉颗粒粒径越大时使冻结较为困难,冰点温度降低。

由表5可知,冰点温度与峰值温度、起始温度、终止温度均呈极显著负相关(r=−0.50、r=−0.52、r=−0.51,P<0.01),峰值温度、起始温度、终止温度越高,冰点温度越低。余世锋等[31]研究表明,糯米粉的热特性温度与淀粉颗粒的网状结构、聚合度,以及淀粉分子结构有关,淀粉颗粒之间空隙越小,网状结构越紧密,聚合度越大,则糊化需要的热量越高,峰值温度、起始温度及终止温度就越高。而淀粉颗粒间的空隙小、结构紧密,大分子物质以空间网状结构存在,游离水较少,不易流动水较多,冰晶形成会受到阻碍,冰点温度就会降低[32-33]。

2.6 影响糯米粉冰点温度的指标主成分分析

对不同品种糯米粉的基本成分、理化指标、热特性数据进行主成分分析,结果如表6。

表 6 影响糯米粉冰点温度的指标主成分分析Table 6. Principal component analysis of indicators that affect the freezing point of glutinous rice flour项目 1 2 3 4 5 6 特征根 6.54 5.04 3.28 2.07 1.52 1.23 贡献率(%) 27.23 21.01 13.66 8.63 6.34 5.12 累计贡献率(%) 27.23 48.24 61.90 70.53 76.87 81.99 由表6可知,6个主成分的累计方差贡献率达到了81.99%,即涵盖了大部分信息,表明前6个主成分能够代表所有原始指标来分析影响糯米粉冰点温度的因素。

表7为原始载荷矩阵经正交旋转法得到的数据结果。在因子1上载荷较大的为糯米粉平均粒径Dav数据,其对冰点温度影响较大,主要反映的是糯米粉粒度对冰点温度的影响;因子2上载荷较大的有峰值温度、起始温度、终止温度,主要反映的是糯米粉热特性对冰点温度的影响;因子3上载荷较大的是谷值粘度与最终粘度,主要反映的是糯米粉糊化特性对冰点温度的影响;因子4上载荷较大的是膨胀能力、衰减值;因子5上载荷较大的是脂肪含量、溶解度;因子6上载荷较大的是蛋白质含量。对各指标的总贡献率进行分析,得到影响糯米粉冰点温度的主要因素为糯米粉的平均粒径Dav、峰值温度、起始温度、终止温度、最终粘度、膨胀能力、粗脂肪含量、溶解度。

表 7 影响冰点温度的指标正交旋转因子载荷Table 7. The orthogonal rotation factor load of the index that affects the freezing temperature1 2 3 4 5 6 共同度 Dav(μm) 0.98 0.05 0.09 0.06 0.08 0.01 0.98 粗蛋白(%) −0.06 0.00 −0.02 −0.02 0.03 0.84 0.72 粗灰分(%) −0.00 −0.28 0.20 −0.43 0.66 0.21 0.79 粗脂肪(%) 0.06 −0.23 −0.24 0.01 0.84 0.20 0.86 粗淀粉(%) −0.22 0.00 0.00 −0.09 0.00 −0.06 0.81 吸水率(%) 0.54 0.31 −0.04 0.17 0.50 −0.31 0.84 溶解度(%) 0.48 0.25 −0.02 −0.23 0.63 −0.01 0.73 膨胀能力(mL·g−1) 0.04 −0.15 0.08 0.89 −0.02 0.21 0.87 胶稠度(mm) 0.21 0.22 0.05 0.38 0.41 −0.14 0.59 峰值粘度(mP·s) 0.53 −0.09 0.59 0.54 −0.09 −0.14 0.96 谷值粘度(mP·s) 0.28 −0.18 0.80 0.33 −0.24 0.06 0.95 衰减值(mP·s) 0.63 0.01 0.25 0.60 0.09 −0.29 0.90 最终粘度(mP·s) 0.21 −0.20 0.93 0.18 −0.08 0.08 0.99 回生值(mP·s) −0.07 −0.12 0.72 −0.27 0.35 0.08 0.91 糊化温度(℃) −0.35 0.51 0.39 −0.41 0.39 −0.16 0.91 峰值温度(℃) 0.15 0.95 −0.12 −0.12 −0.11 −0.01 0.96 起始温度(℃) −0.03 0.97 −0.10 −0.07 0.00 −0.06 0.97 终止温度(℃) 0.20 0.92 −0.20 −0.12 −0.08 −0.06 0.94 糊化焓ΔH(J·g−1) −0.15 0.21 −0.28 −0.07 −0.42 −0.63 0.73 3. 结论

不同糯米粉冰点温度分布在−1.35~−2.65 ℃之间,主要集中在−1.5~−2.5 ℃范围内,并在不同理化指标的测定结果基础上,基于相关性分析和主成分分析分析,影响糯米粉冰点温度的关键因素主要为糯米粉的糯米粉平均粒径、糯米粉的热特性(峰值温度、起始温度、终止温度)、最终粘度、粗脂肪含量和溶解度,而这些指标均与糯米粉团的冰点温度呈负相关。因此,实际应用冰点温度冻结和贮藏技术时,若想降低糯米粉团的冰点温度,可考虑减小糯米粉的平均粒径,增加糯米粉里的脂肪含量及其溶解度,亦可通过提高糯米粉的峰值温度、起始温度和终止温度来实现。若要提高其冰点温度,则相反。实验范围内,优糯6211、黑糯米纯粉、预糊化糯米粉较为适合制作冰点冷冻汤圆。

-

表 1 不同糯米粉基本成分分析

Table 1 Analysis of the basic components of different glutinous rice flour

样品 水分(%) 灰分(%) 淀粉(%) 破损淀粉(%) 蛋白质(%) 脂肪(%) 糯优2号 11.2±0.11h 0.23±0.01m 86.49±0.37i 3.52±0.01u 5.89±0.08o 0.71±0.01lm 优糯6211 9.70±0.15l 0.16±0.00o 90.40±0.11cd 4.24±0.03p 5.62±0.06p 0.61±0.03n 绍糯9714 10.50±0.14j 0.21±0.01n 86.30±0.45i 3.82±0.05t 8.44±0.04c 1.22±0.01g 血糯 10.10±0.13k 0.23±0.01m 90.85±0.11bc 5.22±0.01m 6.54±0.06lm 2.65±0.05b 嘉糯1优6号 10.30±0.15jk 0.33±0.01i 91.13±0.13ab 5.62±0.01j 8.23±0.05d 1.05±0.04h 皖垦糯 8.60±0.20n 0.23±0.00m 88.29±0.11g 5.76±0.04g 9.15±0.06a 0.84±0.01k 武育糯16号 11.50±0.42efg 0.17±0.01o 85.15±0.17jk 6.20±0.01c 8.73±0.06b 0.76±0.02l 苏御糯 11.30±0.10gh 0.53±0.01e 83.46±0.41m 6.06±0.03e 7.48±0.04g 0.68±0.01m 丹旱稻53 10.30±0.21jk 0.17±0.01o 91.49±0.31a 4.91±0.04n 9.15±0.08a 0.73±0.06lm 连糯1号 9.50±0.09l 0.26±0.01l 86.59±0.21i 3.84±0.08t 7.24±0.06hi 0.60±0.01n 南粳46 9.20±0.08m 0.38±0.01g 90.12±0.37de 5.36±0.04l 5.38±0.06q 0.82±0.05k 东北粳糯 11.60±0.01ef 0.43±0.01f 91.65±0.20a 4.94±0.01n 6.20±0.03n 0.84±0.01k 江西籼糯 11.20±0.02h 0.23±0.01m 88.88±0.19f 5.74±0.02gh 6.44±0.03m 0.98±0.02i 安徽粳糯 10.50±0.01j 0.31±0.01j 86.62±0.66i 5.65±0.03ij 6.57±0.08l 1.76±0.03d 信阳籼糯 10.90±0.01i 0.56±0.01d 87.40±0.17h 6.10±0.03de 6.74±0.11k 0.84±0.02k 浙江籼糯 11.40±0.01fgh 0.36±0.00h 83.31±0.31n 5.85±0.05f 7.74±0.02e 0.59±0.04n 2014越南籼糯 12.40±0.02b 0.26±0.01l 84.77±0.31kl 4.53±0.02o 7.61±0.04f 0.76±0.01l 吉林粳糯 12.10±0.03c 0.28±0.01k 91.49±0.13a 5.46±0.01k 7.01±0.10j 1.27±0.08g 湖南水磨籼糯米粉 11.90±0.01cd 0.29±0.01k 88.40±0.07fg 6.34±0.01b 7.17±0.06i 0.74±0.03lm 泰国水磨糯米粉 12.60±0.01b 0.28±0.01k 85.47±0.10j 6.51±0.02a 7.32±0.09h 1.54±0.06e 河北粳糯水磨粉 12.90±0.02a 0.58±0.01c 91.24±0.60ab 6.13±0.03d 5.99±0.13o 1.33±0.01f 半干法黑糯米纯粉 11.70±0.03de 1.14±0.01b 89.54±0.54e 4.04±0.01r 8.67±0.06b 2.07±0.03c 黑糯米纯粉 10.30±0.05jk 1.22±0.02a 89.76±0.11e 4.10±0.01q 8.22±0.04d 3.18±0.05a 半干法辊磨粳糯米 11.60±0.08ef 0.34±0.01i 89.94±0.38de 5.69±0.04hi 8.27±0.05d 0.92±0.01j 预糊化糯米粉 7.80±0.08o 0.22±0.01mn 84.56±0.28lm 3.92±0.01s 5.65±0.10p 1.72±0.02d 注:表中基本成分(除水分)的数据均为干基;同列不同小写字母表示差异显著(P<0.05),表2~表4同。 表 2 糯米粉的理化性质

Table 2 The physicochemical properties of glutinous rice flour

样品 (D90-D10)/D50 Dav(μm) 吸水率(%) 溶解度(%) 胶稠度(mm) 膨胀能力(mL·g−1) 糯优2号 1.58±0.01c 6.87±0.57q 2.24±0.01efghij 0.77±0.03i 142.20±0.48i 4.30±0.21t 优糯6211 1.46±0.01f 7.47±0.04p 2.15±0.03ghijk 1.25±0.02e 162.20±0.27c 3.90±0.19t 绍糯9714 1.57±0.02c 8.56±0.02mn 2.15±0.01ghijk 1.15±0.01f 109.00±0.11p 7.70±0.17r 血糯 1.69±0.03b 6.59±0.06q 2.26±0.02efghi 0.51±0.04m 129.40±0.61l 35.70±0.21a 嘉糯1优6号 1.43±0.01f 8.26±0.03n 2.21±0.02fghij 0.68±0.01j 155.50±0.33e 17.30±0.46m 皖垦糯 1.43±0.01f 7.77±0.01op 2.08±0.01jkl 0.55±0.00kl 116.40±0.20n 32.70±0.29d 武育糯16号 1.57±0.05c 7.92±0.11o 2.14±0.02hijk 0.27±0.02p 155.40±0.52e 34.00±0.18c 苏御糯 1.66±0.11b 9.60±0.12l 1.95±0.01l 0.38±0.01no 85.00±0.49r 12.30±0.50o 丹旱稻53 1.45±0.02f 8.86±0.03m 2.09±0.01ijkl 0.41±0.00n 115.10±0.60o 4.90±0.050s 连糯1号 1.52±0.03de 7.79±0.07op 2.22±0.02efghij 0.25±0.02p 146.00±0.45g 35.20±0.30b 南粳46 1.50±0.00e 8.26±0.03n 2.00±0.01kl 0.41±0.01n 72.90±0.50s 11.70±0.20p 东北粳糯 1.70±0.01b 6.62±0.02q 2.34±0.01def 0.87±0.02h 108.60±0.38p 9.90±0.18q 江西籼糯 1.28±0.01g 7.54±0.01p 2.07±0.01jkl 0.52±0.04lm 119.30±0.11m 19.90±0.06j 安徽粳糯 1.82±0.02a 10.53±0.19k 2.15±0.02ghijk 0.56±0.01k 132.70±0.16k 35.50±0.04ab 信阳籼糯 1.55±0.05cd 8.44±0.27n 2.27±0.00efgh 0.85±0.02h 143.80±0.06h 20.40±0.22i 浙江籼糯 1.29±0.06g 60.47±0.14c 2.44±0.01d 1.07±0.01g 155.60±0.29e 25.10±0.47g 2014越南籼糯 0.80±0.01k 45.79±0.06f 2.35±0.00def 1.65±0.00c 154.90±0.24e 27.70±0.04f 吉林粳糯 1.12±0.02h 55.46±0.42e 2.16±0.01ghijk 0.37±0.02o 142.80±0.26i 13.90±0.02n 湖南水磨籼糯米粉 0.86±0.00j 39.13±0.02g 2.22±0.04efghij 0.40±0.01no 162.10±0.30c 19.10±0.17k 泰国水磨糯米粉 0.92±0.02i 38.61±0.04h 2.38±0.01de 0.67±0.01j 151.40±0.45f 28.40±0.31e 河北粳糯水磨粉 1.15±0.01h 57.67±0.22d 2.32±0.01defg 0.53±0.04klm 170.00±0.78a 25.50±0.21g 半干法黑糯米纯粉 1.12±0.00h 21.61±0.03j 3.01±0.04b 1.67±0.03c 134.30±0.16j 7.80±0.11r 黑糯米纯粉 1.42±0.02f 23.53±0.20i 2.43±0.03d 2.17±0.01b 160.00±0.62d 9.70±0.15q 半干法辊磨粳糯米 0.89±0.01ij 78.11±0.28b 2.60±0.01c 1.53±0.01d 89.40±0.45q 18.30±0.45l 预糊化糯米粉 1.30±0.01g 88.05±0.22a 6.86±0.43a 2.26±0.02a 165.20±0.45b 21.50±0.11h 表 3 糯米粉糊化特性分析

Table 3 The pasting characteristics of the glutinous rice flour

样品 峰值粘度(mP·s) 谷值粘度(mP·s) 衰减值(mP·s) 最终粘度(mP·s) 回生值(mP·s) 糊化温度(℃) 糯优2号 1242.00±2.80h 572.00±1.40p 670.00±1.40hijk 741.00±5.70o 169.00±4.20k 80.40±0.60b 优糯6211 1449.00±9.90gh 768.00±0.00m 681.00±9.90hijk 952.00±4.20l 184.00±4.20j 83.23±0.10b 绍糯9714 616.00±7.10i 205.50±3.50r 410.50±3.50jk 297.00±4.20q 91.50±0.70m 71.88±0.00cde 血糯 1657.50±6.40efg 666.00±0.00o 991.50±6.40efghi 836.00±2.80n 170.00±2.80k 69.83±0.60def 嘉糯1优6号 1255.00±18.40h 570.50±14.80p 684.50±3.50hijk 756.50±19.10o 186.00±4.20j 80.40±0.60b 皖垦糯 1887.00±1.40def 965.00±7.10ij 922.00±5.70fghi 1270.50±4.90h 305.50±2.10d 72.68±0.00cde 武育糯16号 2198.50±6.40d 1016.50±0.70gh 1182.00±7.10defg 1250.50±3.50h 234.00±4.20gh 69.85±0.60def 苏御糯 2143.00±25.50d 1335.00±1.40e 808.00±240ghij 1798.50±3.50e 463.50±2.10b 72.60±0.00cde 丹旱稻53 576.50±4.90i 263.50±0.70q 313.00±5.70k 366.50±2.10p 103.00±1.40l 73.10±0.60cd 连糯1号 1844.00±19.80defg 856.00±4.20l 988.00±24.00efghi 1092.00±4.20k 236.00±0.00gh 70.25±0.00def 南粳46 1573.50±0.70fgh 855.00±33.90l 718.50±33.20hijk 1243.00±32.50h 388.00±1.40c 73.50±1.30cd 东北粳糯 2238.00±1.40d 948.50±0.70jk 1289.50±2.10def 1133.50±7.80j 185.00±7.10j 68.25±0.50ef 江西籼糯 1719.00±9.90efg 1000.00±0.00h 719.00±9.90hijk 1256.00±9.90h 256.00±9.90f 73.55±0.00cd 安徽粳糯 1713.00±5.70efg 715.00±7.10n 998.00±12.70efghi 912.50±2.10m 197.50±4.90i 69.90±0.70def 信阳籼糯 1693.50±26.20efg 1108.00±15.60f 585.50±10.60ijk 1346.50±7.80g 238.50±7.80gh 81.18±0.50b 浙江籼糯 3458.00±8.50b 1651.00±4.20c 1807.00±4.20b 1880.50±3.50d 229.50±0.70h 69.45±0.10def 2014越南籼糯 3233.00±0.00b 1811.00±5.70b 1422.00±5.70cd 2083.50±7.80c 272.50±2.10e 70.63±0.50def 吉林粳糯 1649.50±4.90efg 922.00±7.10k 727.50±12.00hijk 1127.00±12.70j 205.00±5.70i 72.28±0.70cde 湖南水磨籼糯米粉 2215.50±19.10d 986.00±2.80hi 1229.50±16.30def 1242.50±4.90h 256.50±7.80f 71.85±1.10cde 泰国水磨糯米粉 4019.00±28.30a 2302.50±2.10a 1716.50±26.20bc 2606.50±9.20a 304.00±7.10d 70.18±0.00def 河北粳糯水磨粉 2723.50±6.40c 1369.00±0.00d 1354.50±6.40cde 1612.50±3.50f 243.50±3.50g 66.075±0.00f 半干法黑糯米纯粉 1624.00±15.60efgh 1037.00±56.60g 587.00±41.00ijk 2213.00±55.20b 1176.00±1.40a 91.70±0.60a 黑糯米纯粉 573.00±7.10i 175.00±2.80s 398.00±4.20jk 251.50±3.50r 76.50±0.70n 71.025±0.00de 半干法辊磨粳糯米 2001.50±9.20de 933.50±6.40k 1068.00±2.80defgh 1208.50±3.50i 275.00±9.90e 68.10±0.60ef 预糊化糯米粉 3096.50±862.00b 565.00±5.70p 2531.50±867.60a 848.00±7.10n 283.00±1.40e 75.75±9.20c 表 4 糯米粉的冰点与热特性测定

Table 4 The freezing point and thermal properties of glutinous rice flour

样品 冰点温度(℃) 起始温度(℃) 峰值温度(℃) 终止温度(℃) 糊化焓ΔH(J·g−1) 糯优2号 −2.10±0.00hij 74.40±0.28a 78.15±0.07c 83.75±0.21c 3.35±0.00a 优糯6211 −2.55±0.07l 74.60±0.14a 78.55±0.35c 82.65±0.64d 3.12±0.07b 绍糯9714 −1.75±0.07ef 60.25±0.07fg 68.45±0.07fg 73.65±0.21kl 1.94±0.07j 血糯 −1.85±0.07fg 65.00±0.28cd 66.75±0.35hi 72.80±0.28lmn 1.69±0.00l 嘉糯1优6号 −2.05±0.07hij 74.05±0.49a 78.35±0.64c 81.45±0.64e 1.52±0.02m 皖垦糯 −2.30±0.00k 64.90±0.42d 70.56±0.08de 75.90±0.85fgh 2.07±0.08i 武育糯16号 −2.20±0.14jk 63.30±0.57e 68.35±0.64fg 72.75±0.49lmn 1.81±0.02k 苏御糯 −1.50±0.14bc 59.90±0.14fg 65.95±0.64i 72.65±0.35mn 1.72±0.00l 丹旱稻53 −1.35±0.07a 64.60±0.85d 70.35±0.64de 75.25±0.35hi 2.63±0.01c 连糯1号 −1.97±0.06gh 62.80±0.42e 68.20±0.99fg 73.30±0.57klm 2.41±0.02e 南粳46 −1.68±0.05de 60.75±0.35f 67.35±0.21gh 72.55±0.64mn 2.21±0.10gh 东北粳糯 −1.40±0.14ab 59.60±0.57g 66.90±0.42hi 72.45±0.49mn 2.14±0.02hi 江西籼糯 −2.05±0.07hij 65.70±0.42c 71.30±0.28d 76.25±0.07fg 1.53±0.07m 安徽粳糯 −1.55±0.07cd 59.45±0.78g 65.75±0.78ij 72.80±0.28lmn 2.32±0.08f 信阳籼糯 −2.10±0.14hij 74.55±0.64a 80.00±0.99b 84.95±0.49b 2.37±0.05ef 浙江籼糯 −1.60±0.14cde 59.80±0.85fg 66.90±0.28hi 72.00±0.85n 2.50±0.09d 2014越南籼糯 −2.00±0.00ghi 62.40±0.28e 68.70±0.28f 74.60±0.28ij 2.24±0.03g 吉林粳糯 −2.05±0.07hij 62.65±0.21e 70.40±0.28de 76.45±0.35f 2.18±0.03gh 湖南水磨籼糯米粉 −2.05±0.07hij 64.50±0.85d 70.15±0.64de 75.35±0.78ghi 2.50±0.01d 泰国水磨糯米粉 −1.65±0.07cde 62.90±1.27e 69.90±0.99e 73.90±0.42jk 0.78±0.00p 河北粳糯水磨粉 −2.15±0.07ijk 54.35±0.78h 64.10±0.85k 69.30±0.57o 1.93±0.06j 半干法黑糯米纯粉 −1.85±0.07fg 60.50±0.42fg 64.70±1.70jk 68.95±0.21o 0.98±0.01o 黑糯米纯粉 −2.55±0.07l 62.40±0.42e 68.65±0.64f 75.55±0.49fgh 1.41±0.02n 半干法辊磨粳糯米 −2.15±0.07ijk 72.35±0.64b 81.25±0.21a 86.10±0.85a 1.35±0.02n 预糊化糯米粉 −2.65±0.07l 72.65±0.78b 77.80±0.85c 84.30±0.57bc 1.96±0.02j 表 5 糯米粉冰点温度与理化性质的相关性分析

Table 5 Correlation analysis between the freezing point and physicochemical properties of glutinous rice flour

指标 冰点温度 指标 冰点温度 蛋白质 0.12 膨胀能力 0.01 灰分 −0.11 胶稠度 −0.44** 脂肪 −0.30* 峰值粘度 0.05 淀粉 0.09 谷值粘度 0.22 峰值温度 −0.50** 衰减值 −0.12 起始温度 −0.52** 最终粘度 0.21 终止温度 −0.51** 回生值 0.08 糊化焓 −0.01 糊化温度 −0.25 吸水率 −0.41** Dav −0.31** 溶解度 −0.50** 注:**表示在0.01水平上极显著相关;*表示在0.05水平上显著相关。 表 6 影响糯米粉冰点温度的指标主成分分析

Table 6 Principal component analysis of indicators that affect the freezing point of glutinous rice flour

项目 1 2 3 4 5 6 特征根 6.54 5.04 3.28 2.07 1.52 1.23 贡献率(%) 27.23 21.01 13.66 8.63 6.34 5.12 累计贡献率(%) 27.23 48.24 61.90 70.53 76.87 81.99 表 7 影响冰点温度的指标正交旋转因子载荷

Table 7 The orthogonal rotation factor load of the index that affects the freezing temperature

1 2 3 4 5 6 共同度 Dav(μm) 0.98 0.05 0.09 0.06 0.08 0.01 0.98 粗蛋白(%) −0.06 0.00 −0.02 −0.02 0.03 0.84 0.72 粗灰分(%) −0.00 −0.28 0.20 −0.43 0.66 0.21 0.79 粗脂肪(%) 0.06 −0.23 −0.24 0.01 0.84 0.20 0.86 粗淀粉(%) −0.22 0.00 0.00 −0.09 0.00 −0.06 0.81 吸水率(%) 0.54 0.31 −0.04 0.17 0.50 −0.31 0.84 溶解度(%) 0.48 0.25 −0.02 −0.23 0.63 −0.01 0.73 膨胀能力(mL·g−1) 0.04 −0.15 0.08 0.89 −0.02 0.21 0.87 胶稠度(mm) 0.21 0.22 0.05 0.38 0.41 −0.14 0.59 峰值粘度(mP·s) 0.53 −0.09 0.59 0.54 −0.09 −0.14 0.96 谷值粘度(mP·s) 0.28 −0.18 0.80 0.33 −0.24 0.06 0.95 衰减值(mP·s) 0.63 0.01 0.25 0.60 0.09 −0.29 0.90 最终粘度(mP·s) 0.21 −0.20 0.93 0.18 −0.08 0.08 0.99 回生值(mP·s) −0.07 −0.12 0.72 −0.27 0.35 0.08 0.91 糊化温度(℃) −0.35 0.51 0.39 −0.41 0.39 −0.16 0.91 峰值温度(℃) 0.15 0.95 −0.12 −0.12 −0.11 −0.01 0.96 起始温度(℃) −0.03 0.97 −0.10 −0.07 0.00 −0.06 0.97 终止温度(℃) 0.20 0.92 −0.20 −0.12 −0.08 −0.06 0.94 糊化焓ΔH(J·g−1) −0.15 0.21 −0.28 −0.07 −0.42 −0.63 0.73 -

[1] LI Y, DING G, YOKOYAMA W, et al. Characteristics of annealed glutinous rice flour and its formation of fast-frozen dumplings[J]. Journal of Cereal Science,2018,79:106−112. doi: 10.1016/j.jcs.2017.09.016

[2] 夏露, 张超, 王立, 等. 冬小麦抗冻蛋白制备及其在汤圆中的应用研究[J]. 食品工业科技,2009,30(11):241−243, 310. [XIA L, ZHANG C, WANG L, et al. Preparation and application of antifreeze proteins extracted from winter wheat bran[J]. Science and Technology of Food Industry,2009,30(11):241−243, 310. XIA L, ZHANG C, WANG L, et al. Preparation and application of antifreeze proteins extracted from winter wheat bran[J]. Science and Technology of Food Industry, 2009, 30(11): 241-243, 310.

[3] 张国治. 糯米粉的品质分析及速冻汤圆品质改良[J]. 冷饮与速冻食品工业,2006,12(2):39−42. [ZHANG G Z. Property analysis of flour of glutinous rice and quality of deep-frozen glutinous rice dough[J]. Beverage & Fast Frozen Food Industry,2006,12(2):39−42. ZHANG G Z. Property analysis of flour of glutinous rice and quality of deep-frozen glutinous rice dough[J]. Beverage & Fast Frozen Food Industry, 2006, 12(2): 39-42.

[4] 周显青, 胡育铭, 张玉荣, 等. 我国速冻汤圆加工及其质量控制技术现状与展望[J]. 粮油食品科技,2014,22(2):6−11. [ZHOU X Q, HU Y M, ZHANG Y R, et al. Status and prospects of processing and quality control for the frozen rice dumplings in China[J]. Science and Technology of Cereals, Oils and Foods,2014,22(2):6−11. doi: 10.3969/j.issn.1007-7561.2014.02.002 ZHOU X Q, HU Y M, ZHANG Y R, et al. Status and prospects of processing and quality control for the frozen rice dumplings in China[J]. Science and Technology of Cereals, Oils and Foods, 2014, 22(2): 6-11. doi: 10.3969/j.issn.1007-7561.2014.02.002

[5] 李真, 安阳, 艾志录, 等. 基于响应面法优化工艺参数改善速冻汤圆品质[J]. 食品与发酵工业,2017,43(8):163−168. [LI Z, AN Y, AI Z L, et al. Optimization of quick-frozen Tang-yuan processing by response surface method[J]. Food and Fermentation Industries,2017,43(8):163−168. LI Z, AN Y, AI Z L, et al. Optimization of quick-frozen Tang-yuan processing by response surface method[J]. Food and Fermentation Industries, 2017, 43(8): 163-168.

[6] CAI J W, CHIANG J H, TAN M, et al. Physicochemical properties of hydrothermally treated glutinous rice flour and xanthan gum mixture and its application in gluten-free noodles[J]. Journal of Food Engineering,2016,186(10):1−9.

[7] LI Z N, WANG L, CHEN Z X, et al. Impact of protein content on processing and texture properties of waxy rice flour and glutinous dumpling[J]. Journal of Cereal Science,2018(81):30−36.

[8] 陈瑾. 速冻汤圆品质与糯米粉粉质相关性及糯米粉配粉研究[D]. 郑州: 河南农业大学, 2019 CHEN J. Study on the correlation between the quality of quick-frozen dumplings and the quality of gulutinous rice flour and the powdering of glutinous rice flour[D]. Zhengzhou: Henan Agricultural University, 2019.

[9] 黄忠民, 陈瑾, 宋会玲, 等. 糯米粉特性与速冻汤圆品质相关性分析[J]. 食品工业科技,2019,40(4):93−99. [HUANG Z M, CHEN J, SONG H L, et al. Correlation between the characteristics of glutinous rice flour and quality[J]. Science and Technology of Food Industry,2019,40(4):93−99. HUANG Z M, CHEN J, SONG H L, et al. Correlation between the characteristics of glutinous rice flour and quality[J]. Science and Technology of Food Industry, 2019, 40(4): 93-99.

[10] 孙威, 陈轩, 庄坤, 等. 调质温度和时间对黑糯米半干法制粉品质的影响[J]. 食品工业科技,2020,41(5):17−22, 30. [SUN W, CHEN X, ZHUANG K, et al. Effect of tempering temperature and time on the quality of semi-dry black glutinous rice flour[J]. Science and Technology of Food Industry,2020,41(5):17−22, 30. SUN W, CHEN X, , ZHUANG K, et al. Effect of tempering temperature and time on the quality of semi-dry black glutinous rice flour[J]. Science and Technology of Food Industry, 2020, 41(5): 17-2, 30.

[11] CJAM K, TVANV, WALSTRA P. Gelation and retrogradation of concentrated starch systems: 2. Retrogradation[J]. Food Hydrocolloids,1996,10(3):355−362. doi: 10.1016/S0268-005X(96)80012-9

[12] 付一帆, 甘淑珍, 赵思明. 几种淀粉的糊化特性及力学稳定性[J]. 农业工程学报,2008,24(10):255−257. [FU Y F, GAN S Z, ZHAO S M. Gelatinization characteristics and mechanical stability of various starch sources[J]. Transactions of the CSAE,2008,24(10):255−257. doi: 10.3321/j.issn:1002-6819.2008.10.052 FU Y F, GAN S Z, ZHAO S M. Gelatinization characteristics and mechanical stability of various starch sources[J]. Transactions of the CSAE, 2008, 24(10): 255-257. doi: 10.3321/j.issn:1002-6819.2008.10.052

[13] 顾玲, 张燕萍. 杂粮粉对糯米粉理化性质的影响[J]. 食品科技,2015,40(2):186−190. [GU L, ZHANG Y P. Impact of grains powder on the physicochemical properties of glutinous rice flour[J]. Food Science and Technology,2015,40(2):186−190. GU L, ZHANG Y P. Impact of grains powder on the physicochemical properties of glutinous rice flour[J]. Food Science and Technology, 2015, 40(2): 186-190.

[14] 钟志友, 张敏, 杨乐, 等. 果蔬冰点与其生理生化指标关系的研究[J]. 食品工业科技,2011,32(2):76−78. [ZHONG Z Y, ZHANG M, YANG L, et al. Study on relation between freezing and physiological and biochemical indexes of fruits and vegetable[J]. Science and Technology of Food Industry,2011,32(2):76−78. ZHONG Z Y, ZHANG M, YANG L, et al. Study on relation between freezing and physiological and biochemical indexes of fruits and vegetable[J]. Science and Technology of Food Industry, 2011, 32(2): 76-78.

[15] ISM Z, ABSAR N, KIM S J, et al. Dsc study of mixtures of wheat flour and potato, sweet potato, cassava, and yam starches[J]. Journal of Food Engineering,2008,86(1):68−73. doi: 10.1016/j.jfoodeng.2007.09.011

[16] CHANVRIER H, UTHAYAKUMARAN S, APPELQVIST I A M, et al. Influence of storage conditions on the structure, thermal behavior, and formation of enzyme-resistant starch in extruded starches[J]. Journal of Agricultural & Food Chemistry,2007,55(24):90−98,83.

[17] LIN Z, GENG D H, QIN W, et al. Effects of damaged starch on glutinous rice flour properties and sweet dumpling qualities[J]. International Journal of Biological Macromolecules,2021,181:390−397. doi: 10.1016/j.ijbiomac.2021.03.160

[18] 宋莹莹. 糯米粉吸水率影响因素的研究[D]. 武汉: 武汉轻工大学, 2013 SONG Y Y. Study on the impacting factors of water absorption of waxy rice flour[D]. Wuhan: Wuhan Polytechnic University, 2013.

[19] ZHANG H, WU F, XU D, et al. Effects of milling methods on the properties of glutinous rice flour and sweet dumplings[J]. Journal of Food Science and Technology Mysore,2020,58,(5):1848−1857.

[20] ERCOLINI D. Pcr-dgge fingerprinting: Novel strategies for detection of microbes in food[J]. Journal of Microbiological Methods,2004,56(3):297−314. doi: 10.1016/j.mimet.2003.11.006

[21] 田斌强, 邓乾春, 谢笔钧. 发芽燕麦淀粉的热特性[J]. 现代食品科技,2014,30(5):98−103. [TIAN B Q, DENG Q C, XIE B J. Thermal properties of the starch from germinated oat[J]. Modern Food Science and Technology,2014,30(5):98−103. TIAN B Q, DENG Q C, XIE B Y. Thermal properties of the starch from germinated oat[J]. Modern Food Science and Technology, 2014, 30(5): 98-103.

[22] KOZLOV I I, SIA S. Effect of amylose content on gelatinization, retrogradation and pasting properties of flours from different cultivars of thai rice[J]. Starch-Stärke,2003,55(9):410−415.

[23] PARK I M, IBANEZ A M, ZHONG F, et al. Gelatinization and pasting properties of waxy and non-waxy rice starches[J]. Starch-Stärke,2007,59(8):388−396.

[24] 余世锋, 张永春, 林佳楠, 等. 玉米淀粉、绿豆淀粉和皱皮豌豆淀粉热特性及回生性质的比较[J]. 食品科技,2013,38(9):136−140. [YU S F, ZHANG Y C, LIN J N, et al. Comparing the thermal and retrogradation properties of corn starch and mung bean starch and wrinkled pea starch[J]. Food Science and Technology,2013,38(9):136−140. YU S F, ZHANG Y C, LIN J N, et al. Comparing the thermal and retrogradation properties of corn starch and mung bean starch and wrinkled pea starch[J]. Food Science and Technology, 2013, 38(9): 136-140.

[25] REDDY C K, CHOI S M, LEE D J, et al. Complex formation between starch and stearic acid: Effect of enzymatic debranching for starch[J]. Food Chemistry,2018,244:136. doi: 10.1016/j.foodchem.2017.10.040

[26] 刘延奇, 秦令祥, 吴史博, 等. 淀粉-脂质复合物的相互作用及研究进展[J]. 食品科技,2009,34(7):209−213. [LIU Y Q, QIN L X, WU S B, et al. Interaction and progress of starch-lipid complex[J]. Food Science and Technology,2009,34(7):209−213. LIU Y Q, QIN L X, WU S B, et al. Interaction and progress of starch-lipid complex[J]. Food Science and Technology, 2009, 34(7): 209-213.

[27] 胡烨, 何建东, 王朋, 等. 养殖大黄鱼冰点调节剂研制[J]. 中国食品学报, 2013, 13(1): 51−60 HU Y, HE J D, WANG P, et al. Development of freezing-point regulator for cultured large yellow croaker[J]. Journal of Chinese Institute of Food Science and Technology, 2013, 13(1): 51−60.

[28] ABBAS T, LAVADIYA D N, KIRAN R. Exploring the use of polyols, corn, and beet juice for decreasing the freezing point of brine solution for deicing of pavements[J]. Sustainability,2021,13(11):5765. doi: 10.3390/su13115765

[29] 李贤勇, 王元凯, 王楚桃. 稻米蒸煮品质与营养品质的相关性分析[J]. 西南农业学报,2001,14(3):21−24. [LI X Y, WANG Y K, WANG C T. Analysis of correlation between quality characters of cooking and nutrition[J]. Southwest China Journal of Agricultural Sciences,2001,14(3):21−24. doi: 10.3969/j.issn.1001-4829.2001.03.005 LI X Y, WANG Y K, WANG C T. Analysis of correlation between quality characters of cooking and nutrition[J]. Southwest China Journal of Agricultural Sciences, 2001, 14(3): 21-24. doi: 10.3969/j.issn.1001-4829.2001.03.005

[30] 曹松, 周洲, 董明, 等. 不同实验室干法制备工艺对糯米粉品质特性的影响[J]. 现代食品,2021(17):60−63, 69. [CAO S, ZHOU Z, DONG M, et al. Effects of dry preparation processes in different laboratories on the quality characteristics of glutinous rice flour[J]. Modern Food,2021(17):60−63, 69. CHAO S, ZHOU Z, DONG M, et al. Effects of dry preparation processes in different laboratories on the quality characteristics of glutinous rice flour[J]. Modern Food, 2021(17): 60-63, 69.

[31] 余世锋, 杨秀春, MENAGER L, 等. 直链淀粉、蛋白质及脂类对大米粉热特性的影响[J]. 食品与发酵工业,2009,35(4):38−42. [YU S F, YANG X C, MENAGER L, et al. Effects of amylose, protein and lipid on the thermal properties of rice flour[J]. Food and Fermentation Industries,2009,35(4):38−42. YU S F, YANG X C, MENAGER L, et al. Effects of amylose, protein and lipid on the thermal properties of rice flour [J]. Food and Fermentation Industries, 2009, 35(4): 38-42.

[32] 应月, 李保国, 董梅, 等. 冰温技术在食品贮藏中的研究进展[J]. 制冷技术,2009,29(2):12−15. [YING Y, LI B G, DONG M, et al. Advances in ice-temperature technique for food storage[J]. Refrigeration Technology,2009,29(2):12−15. YING Y, LI B G, DONG M, et al. Advances in ice-temperature technique for food storage[J]. Refrigeration Technology, 2009, 29(2): 12-15.

[33] 赵凯, 张守文, 方桂珍, 等. 湿热处理对玉米淀粉颗粒结构及热焓特性的影响[J]. 食品与发酵工业,2004,30(10):17−20. [ZHAO K, ZHANG S W, FANG G Z, et al. Effects of HMT on the granule and crystalline property of maize starch[J]. Food and Fermentation Industries,2004,30(10):17−20. ZHAO K, ZHANG S W, FANG G Z, et al. Effects of HMT on the granule and crystalline property of maize starch[J]. Food and Fermentation Industries, 2004, 30(010): 17-20.

下载:

下载:

下载:

下载: